High-speed structure illumination optical microscope system and method based on digital micromirror device

A digital micromirror device and structured lighting technology, applied in optics, microscopes, optical components, etc., can solve the problems of slow speed and low utilization rate of microscopic light energy, and achieve the elimination of image quality. The effect of high utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

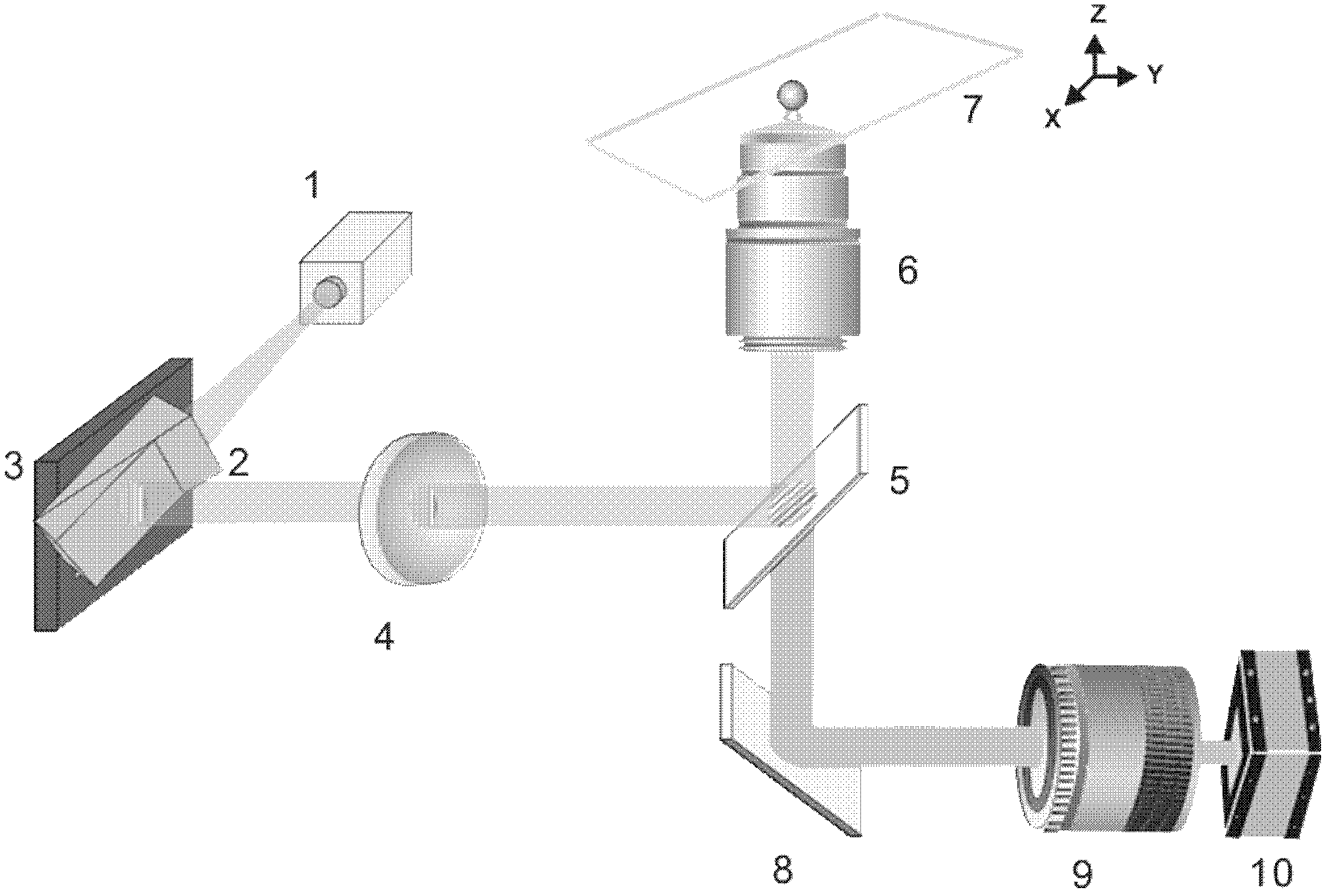

[0050] Such as figure 1 As shown, a high-speed structured illumination optical microscope system based on a digital micromirror device includes an illumination source 1, a beam splitting prism 2 arranged on the light path of the illumination source, and a structured light generator 3 arranged on the reflected light path of the beam splitting prism 2 , the lens 4 that is arranged on the transmitted light path of the beam splitter 2, the beam splitter 5 that is arranged on the lens light path, the microscopic objective lens 6 and the stage 7 that are arranged on the light path above the beam splitter 5, and the light beam that is arranged under the beam splitter 5 Reflective mirror 8 and tube lens 9 on the road, the CCD camera 10 that is arranged on the tube lens rear.

[0051] Generally, the structured light generator 3 is a digital micromirror device DMD. Illumination light source can choose single-color or double-color LED light source according to different samples

[0052...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com