High-transmittance low-reflection electromagnetic screening structure for liquid crystal display screen and manufacturing method for structure

An electromagnetic shielding structure, liquid crystal display technology, applied in the fields of magnetic field/electric field shielding, electrical components, optics, etc., can solve the problems of high reflectivity of the transparent conductive shielding layer, affecting the display effect, etc. Readability, the effect of reducing distractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] Such as Figure 4 shown.

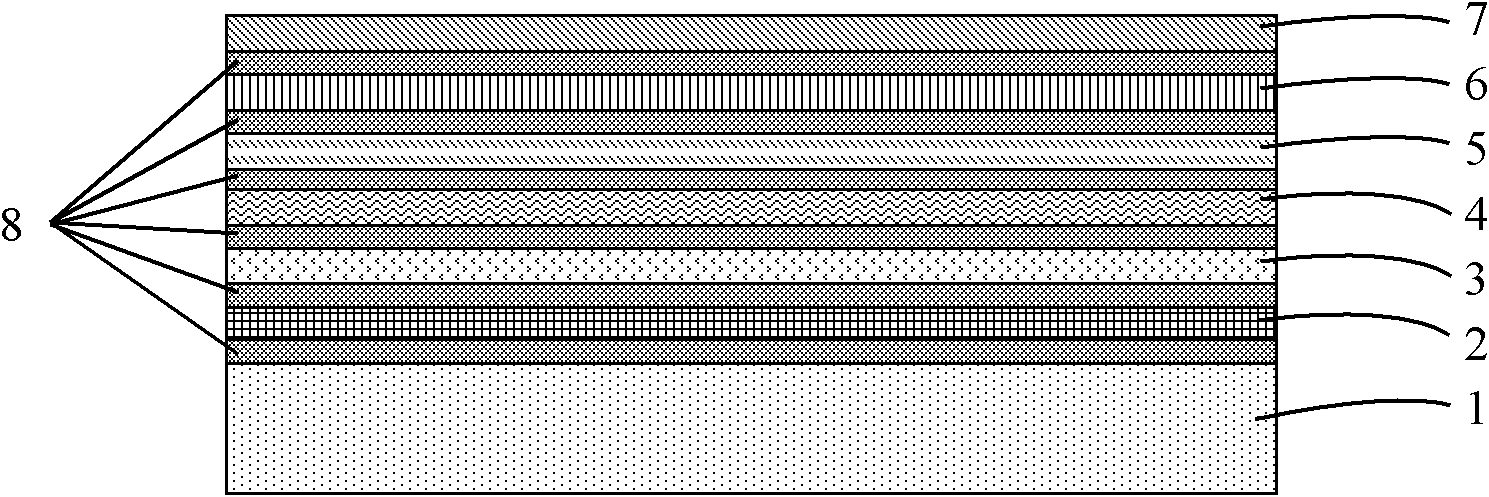

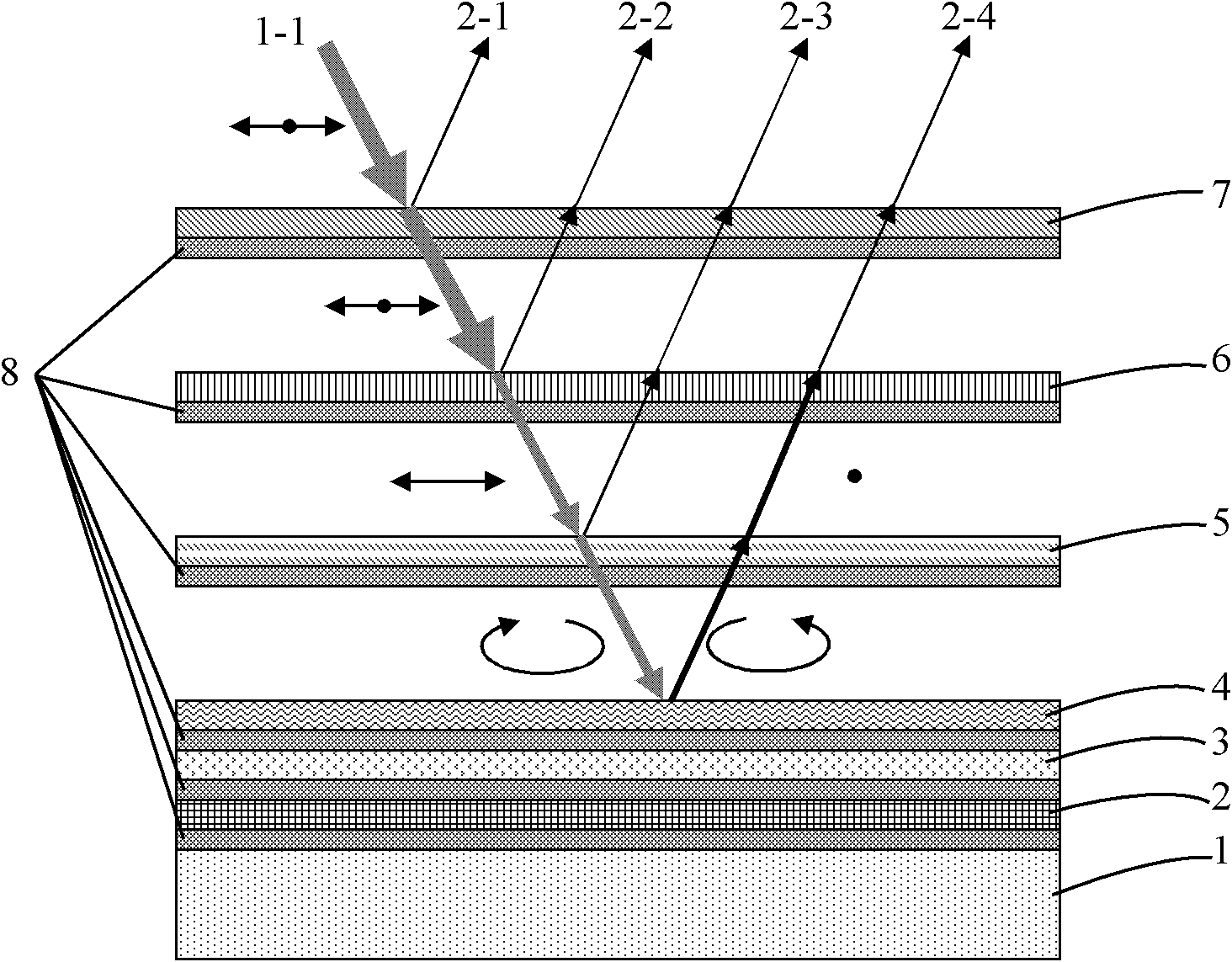

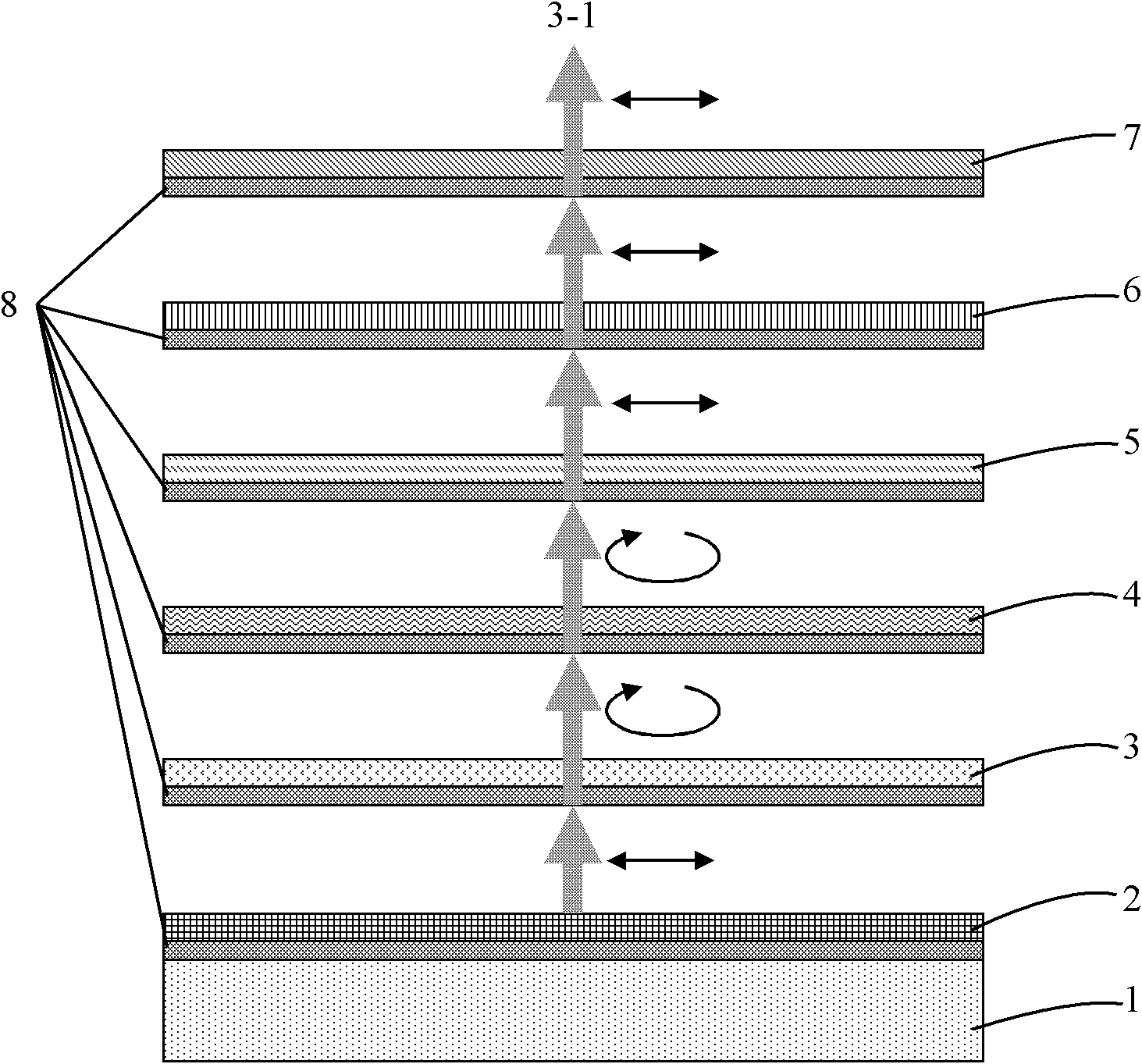

[0037] A method for manufacturing an electromagnetic shielding structure with high transmission and low reflection for a liquid crystal display, comprising the following steps: (1) optically bonding the anti-reflection layer 7 and the polarizing layer 6 through a transparent optical adhesive 8 (such as rolling bonding, Liquid glue bonding, etc., the same below) The binding process is solidified into a double-layer structure. (2) The double-layer structure and the quarter-wave retardation layer 5 are cured into a three-layer structure through the transparent optical adhesive 8 by optical bonding and binding process. (3) The three-layer structure and the indium tin oxide transparent conductive layer 4 are cured into a four-layer structure through the transparent optical adhesive 8 by an optical bonding process. (4) The four-layer structure and the quarter-wave retardation layer 3 are cured through the transparent optical adhesive 8 by an optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com