Method for improving resistance accuracy of buried resistor in PCB (printed circuit board)

A technology of PCB board and embedded resistors, which is applied in the direction of assembling printed circuits with electrical components, containing printed electrical components, etc., can solve the problems of poor resistance value accuracy and difficulty in meeting special application requirements for resistance value accuracy, so as to reduce difficulty and improve The effect of commercialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

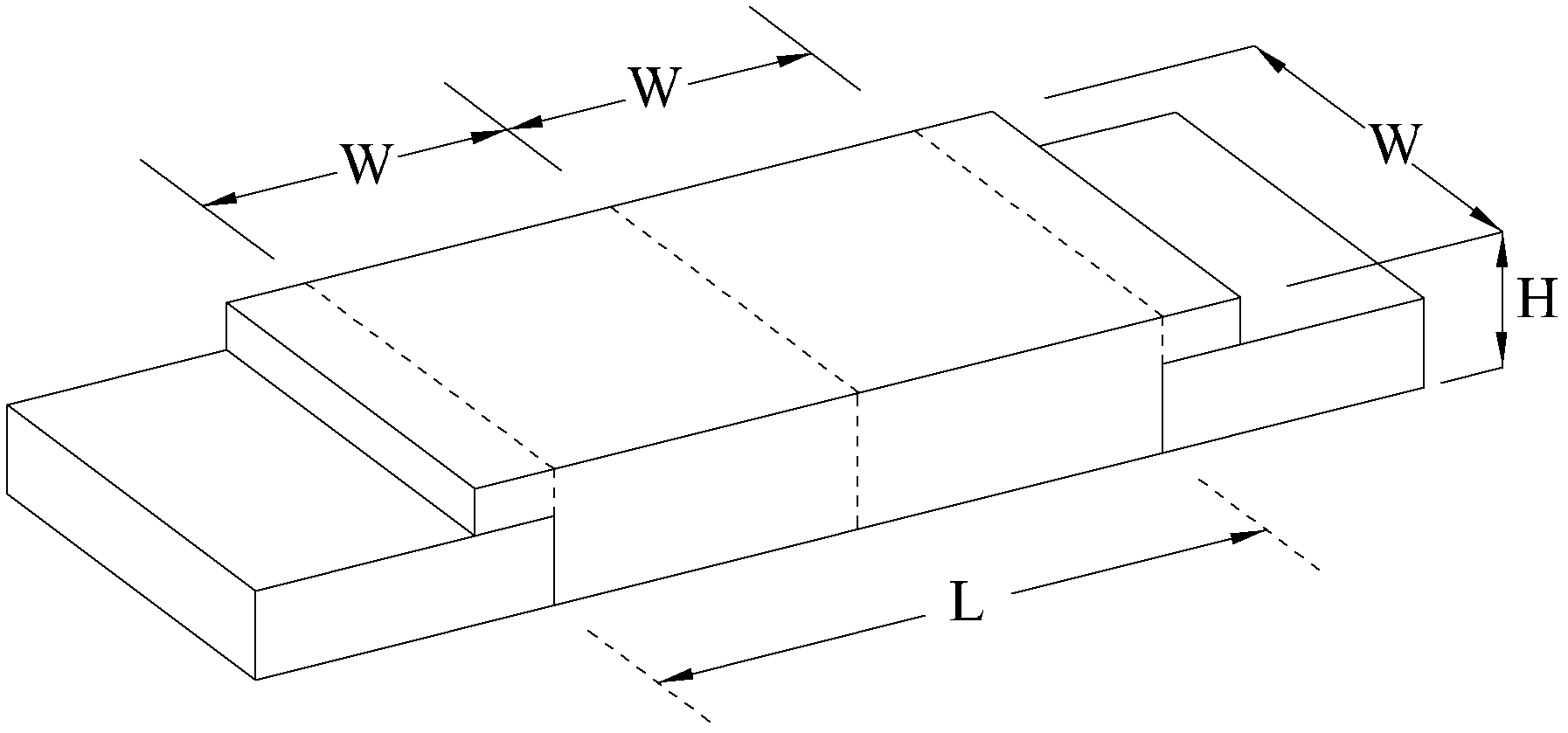

[0022] Such as figure 1 Shown is a schematic diagram of the calculation of the resistance value of the silk-printed buried resistor.

[0023] The calculation formula of buried resistance is: R=ρ×L / (W×H).

[0024] For a square resistance with a specified thickness, the formula for calculating the buried resistance is: R=R◇×L / W. In the formula, R represents the resistance value, R◇ represents the square resistance value, L represents the length of the resistance, and W represents the width of the resistance.

[0025] Square resistance value: When the resistance material is the same and the resistance thickness is the same, the resistance value of the square area per unit area is the same.

[0026] It can be seen from the definition that the square resistance value is not only related to the material properties, but also related to the resistance thickness (for example: R◇=1000Ω / square / 14μm, which means that the square resistance thickness after complete baking is required to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com