Irradiation method for reducing mercury ion valence state in refrigerated livestock, poultry and fish

A mercury ion and irradiation technology, which is applied in the field of radiation processing, can solve the problems such as the content of positive divalent mercury ions exceeds the standard, and achieve the effects of improving safety, simple process, and improving hygienic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

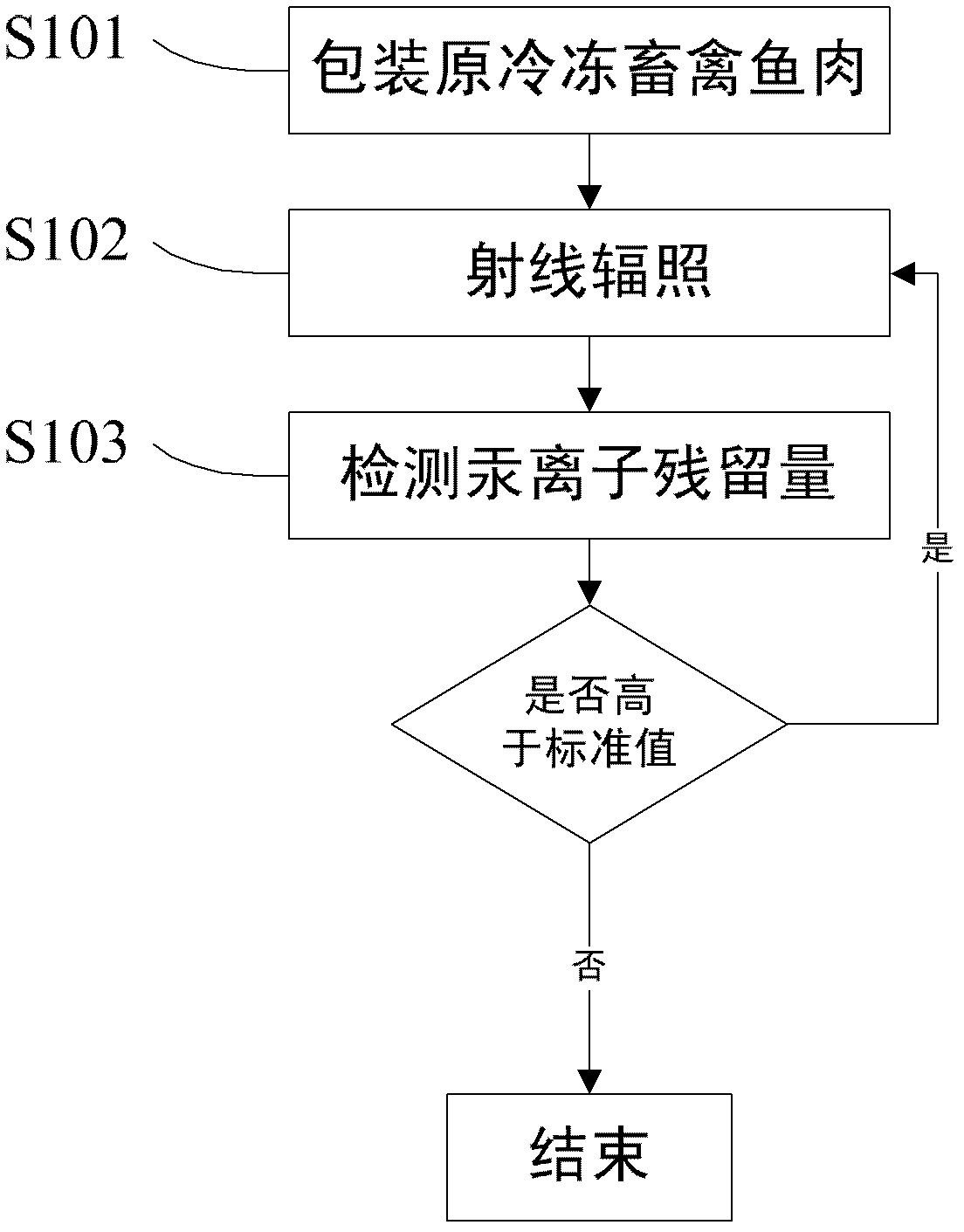

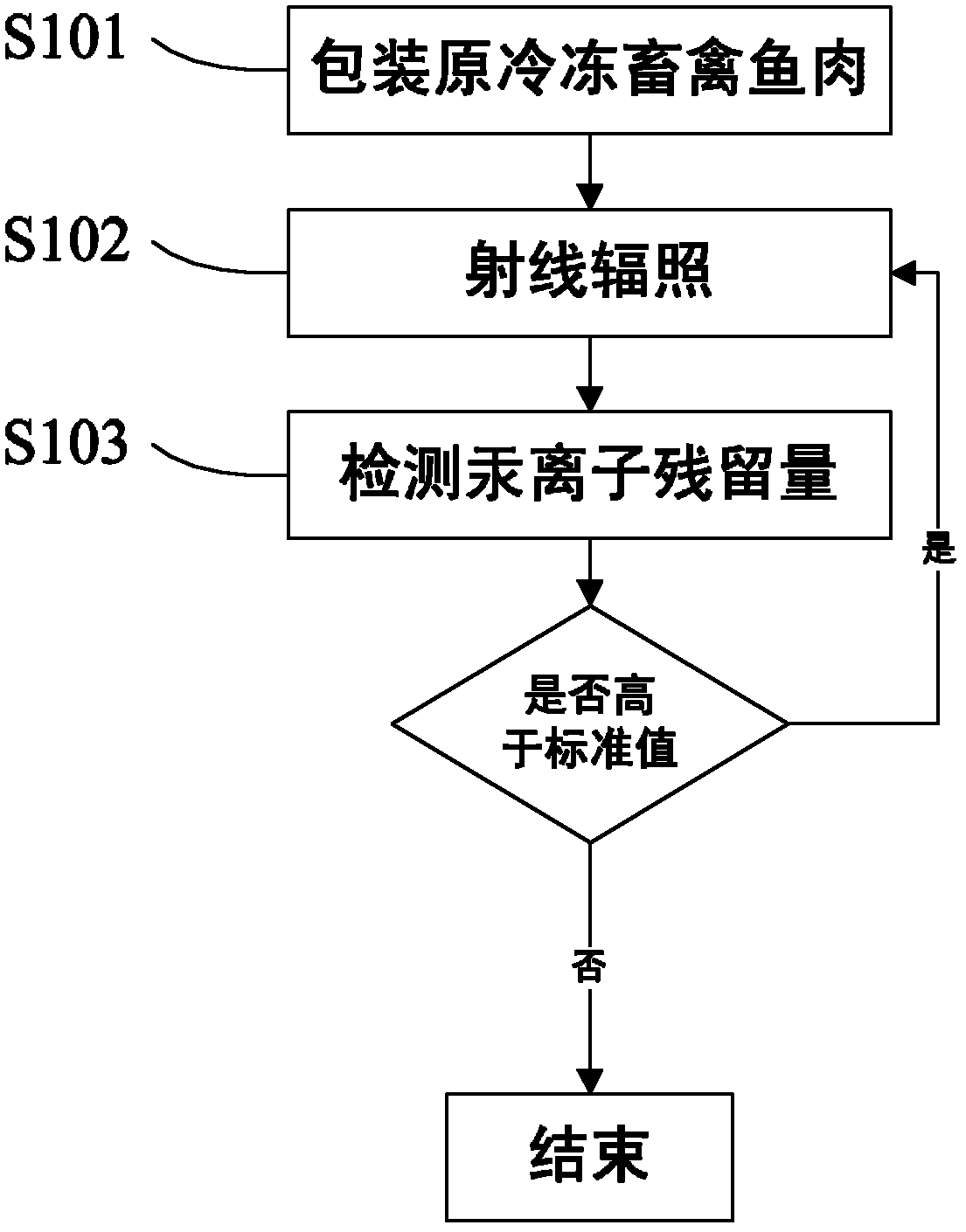

[0031] as attached figure 1 Shown, a kind of irradiation method that reduces the valence state of mercury ion in frozen livestock and poultry fish, comprises the following steps:

[0032] Step S101, packaging the original frozen livestock, poultry and fish meat with excess positive divalent mercury ion residues;

[0033] Step S102, use 60 Co gamma ray or 10MeV electron beam irradiation, the total irradiation dose is 6-30kGy, and the unevenness of irradiation dose is less than 1.25;

[0034] Step S103: Detect the residual amount of positive divalent mercury ions in the original frozen livestock, poultry and fish meat irradiated in step 2. If it is higher than the standard value, repeat step 2 under the premise that the total irradiation dose does not exceed 30 kGy until positive divalent mercury ion Ion residues are equal to or lower than the standard value.

Embodiment 2

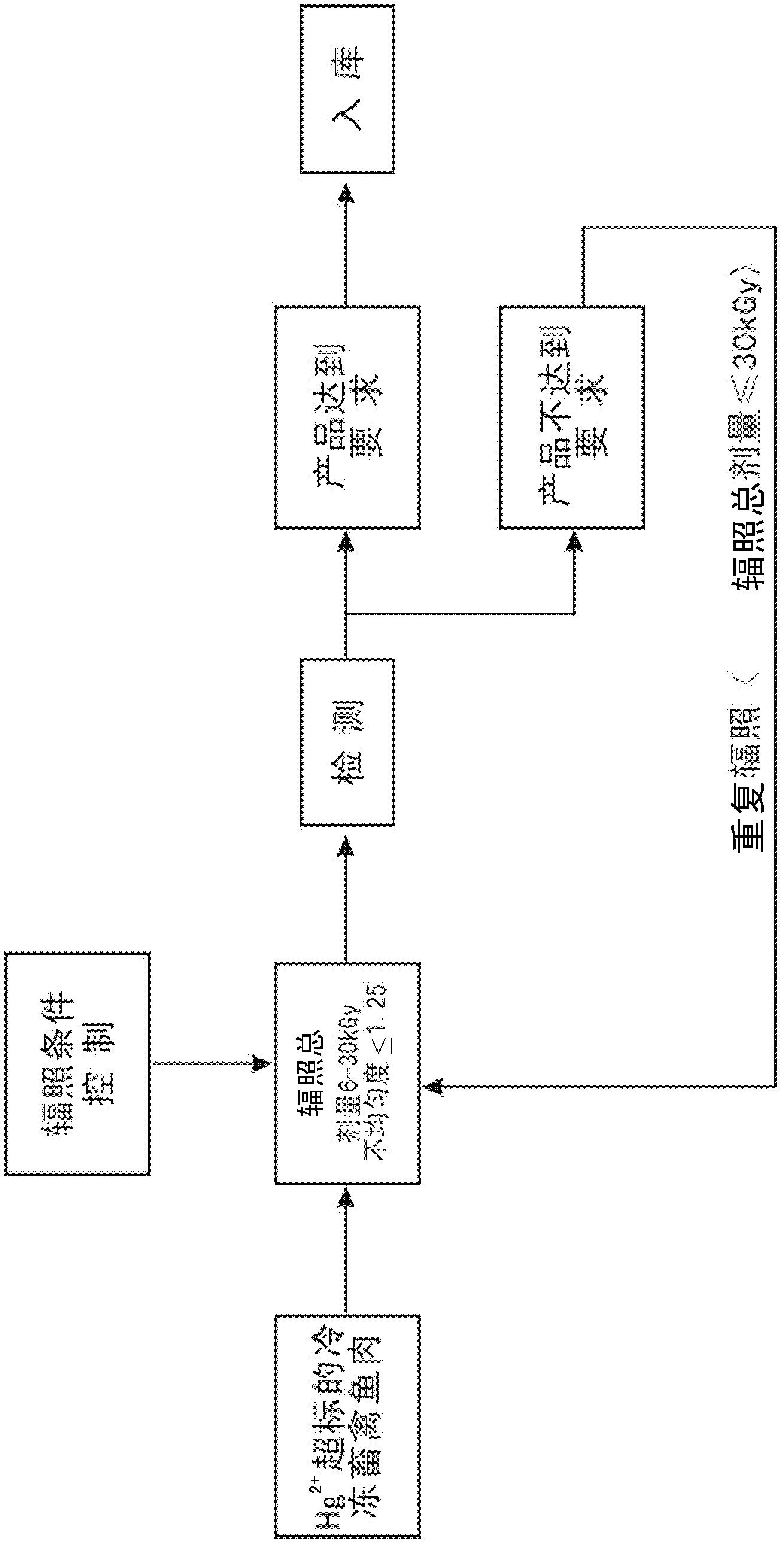

[0036] Electron beam irradiation -18 ℃ frozen beef:

[0037] as attached figure 2 As shown, positive divalent mercury ions (Hg 2+ ) residual amount (calculated by total mercury, the same below) is 0.08mg / kg, packed in polyethylene plastic bags, 1kg for each inner package, the total thickness (i.e. height) of the outer packing box shall not exceed 10cm, and the length and width shall not exceed 50cm, the total weight does not exceed 15kg. The irradiation conditions are irradiating with 10MeV electron beams, the dose rate is 5kGy / min, the absorbed dose is 8kGy, the unevenness of the irradiation dose is 1.25, the air temperature in the irradiation room is controlled below 20°C, and the whole irradiation process is within 2 hours After completion, after irradiation, put it into a freezer at -18°C for detection, in which positive divalent mercury ions (Hg 2+ ) if the residual amount falls below 0.05mg / kg, it meets the requirements of GB2762-2005 national standard; if it does not ...

Embodiment 3

[0039] 60 Co irradiated -18°C frozen fish (shrimp) meat:

[0040] as attached figure 2 As shown, positive divalent mercury ions (Hg 2+ ) with a residual amount of 0.20 mg / kg, and it is usually packed in polyethylene plastic bags (or vacuum packed). The size and weight of the inner packaging can be according to the requirements of the manufacturer, there is no specific regulation, but the outer packaging is kept in a foam plastic box, and its size and specification should meet the requirements of the manufacturer. 60 Co transfer irradiation box is required to improve 60 Co energy utilization rate, the air temperature in the irradiation room is controlled below 20°C, and the irradiation process is completed within 12 hours. Since the irradiation process takes more than 2 hours, insulation measures must be taken to ensure that the product temperature is below -18°C to prevent accidents. Temperature rises lead to product failure. The first irradiation process dose is 8kGy, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com