Sheet-form preparation and method for producing the same

A preparation and tablet technology, applied in the field of gel-type tablet preparations, can solve problems such as difficulty in maintaining the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] 3 parts by weight of crystalline cellulose A (average particle diameter: 20 μm) was added to 74 parts by weight of purified water, and ultrasonic dissolution and dispersion were performed. Add 10 parts by weight of water-soluble gelatin (about 100,000 average molecular weight, about 8.6 mol% of hydroxyproline) derived from fish (tilapia) therein, dissolve it at a temperature of normal temperature to 40° C., and further add Add 10 parts by weight of D-sorbitol, 3 parts by weight of PEG4000 to make it dissolve, and distribute 1g to 5cm 2 The plastic blister (Cryomold (square) No. 3, manufactured by Sakura Finetek Japan Co., Ltd.) was cooled and solidified at 2 to 8°C for 1 day and night to obtain a sheet-like preparation.

Embodiment 2

[0107] 3 parts by weight of crystalline cellulose A (average particle diameter: 20 μm) was added to 74 parts by weight of purified water, and ultrasonic dissolution and dispersion were performed. 10 parts by weight of gelatin (derived from fish) (average molecular weight: 100,000, hydroxyproline content about 8.6 mol%) was added thereto, dissolved at a temperature of 50 to 70°C, and vibrated at a constant temperature of 40°C. In this solution, add 10 parts by weight of D-sorbitol, 3 parts by weight of PEG4000 to make it dissolve, and distribute 1g to 5cm 2 The plastic blister (Cryomold (square) No. 3, manufactured by Sakura Finetek Japan Co., Ltd.) was cooled and solidified at 2 to 8°C for 1 day and night to obtain a sheet-like preparation.

Embodiment 3~7

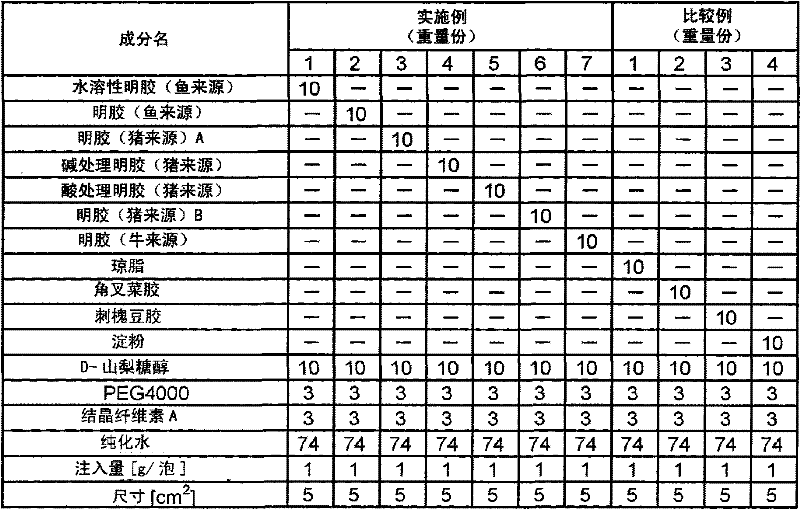

[0109] Except having adopted the composition shown in Table 1, it operated in the same procedure as Example 2, and obtained the sheet-form preparation.

[0110] Use gelatin (pig origin) A (average molecular weight about 85,000, hydroxyproline amount about 9.2 mole %) in embodiment 3, use alkali treatment gelatin (pig origin) (average molecular weight 180,000, hydroxyproline amount) in embodiment 4 Acid amount is about 9.2 mol%), acid-treated gelatin (porcine origin) is used in Example 5 (average molecular weight 100,000, hydroxyproline amount is about 9.2 mol%), and gelatin (porcine origin) B (average Molecular weight about 100,000, hydroxyproline content about 9.4 mol%), gelatin (bovine origin) was used in Example 7 (average molecular weight about 200,000, hydroxyproline content about 9.5 mol%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com