Electric shear type lifting platform

A lifting platform and electric scissors technology, which is applied in the direction of lifting frame, lifting device, transmission device, etc., can solve the problems of hydraulic oil pollution, poor stability, complicated design and manufacturing, etc., and achieve the saving of mechanism manufacturing cost, less power loss, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

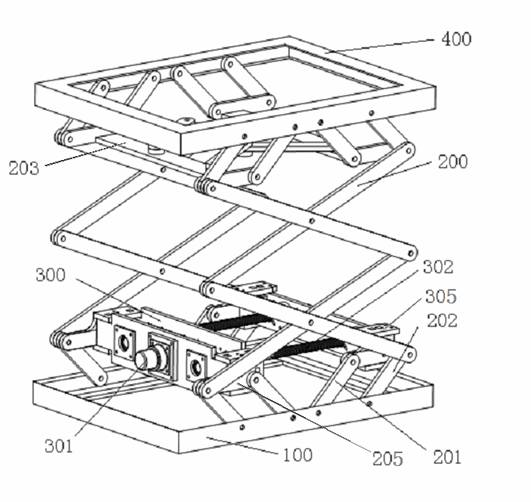

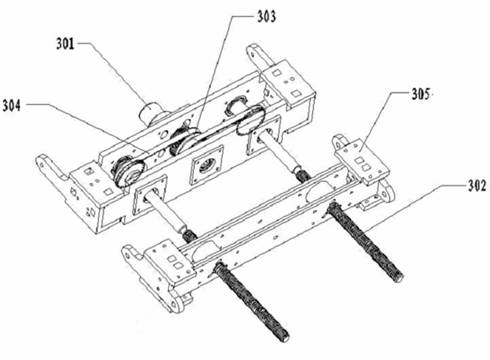

[0022] see figure 1 and figure 2 , an electric scissor lift platform, comprising an upper movable bearing platform 400, a lower base 100, a mechanical lift mechanism 200 and a power drive mechanism 300, the mechanical lift mechanism 200 has a multi-layer scissor assembly, and each layer of the scissor assembly is made of rigid Composed of rods, the top of the uppermost scissors of the mechanical lifting mechanism 200 supports the upper movable bearing platform 400 and is movably connected with the upper movable bearing platform 400, and the bottom end of the lowermost scissors of the mechanical lifting mechanism 200 supports the base 100 and is connected to the lower movable bearing platform 400. The base 100 is movably connected; the power drive mechanism 300 is installed above the lower base 100 and between two identical sets of multi-layer scissors assemblies that are arranged parallel to each other. The power drive mechanism 300 is a screw horizontal track feed actuator, ...

Embodiment 2

[0027] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

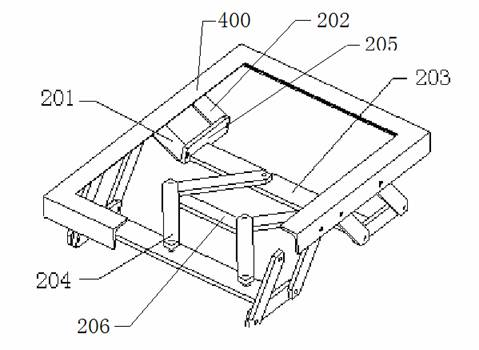

[0028] see Figure 3 ~ Figure 5 , in this embodiment, the folding rod stabilization mechanism is composed of two sets of folding rods 204 and one coupling cross bar 206 to form a parallelogram linkage linkage mechanism, and the head and tail ends of each set of folding rods 204 are respectively hinged with two crosspieces 203 , the corresponding rods of the two sets of folding rods 204 are arranged parallel to each other, and the middle bending hinge pairs of the two sets of folding rods 204 are connected with the two ends of the coupling cross bar 206 through compound hinges. In this embodiment, the folding rod stabilization mechanism can not only ensure the horizontal balance of the lifting platform, but also limit the degree of freedom of the scissors, so that the lifting platform will not reach the dead point of movement and hinder normal movement. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com