Sludge drying treatment method and device

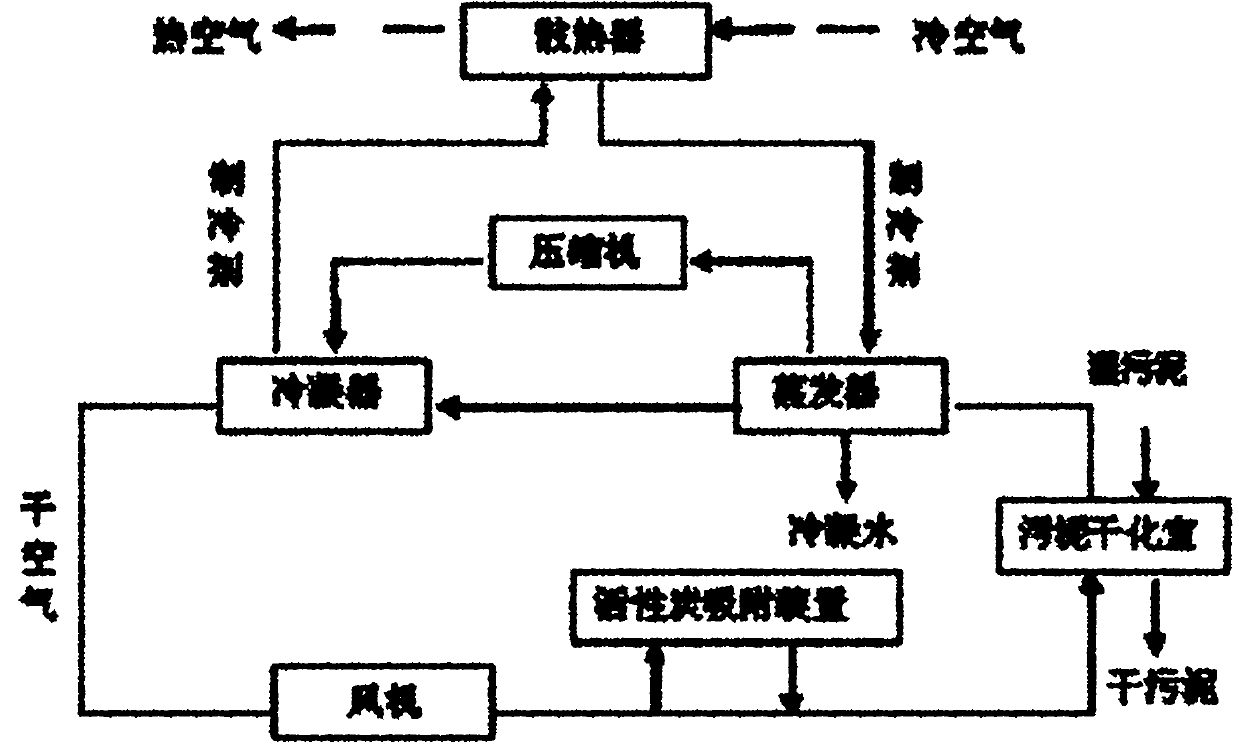

A sludge drying and treatment device technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, can solve the problems of low thermal efficiency, high operation cost, and large investment, and achieve the reduction of sludge volume and operation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

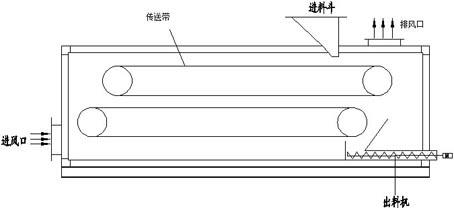

[0027] In the following, a specific description will be given by taking the application of the present invention in a sludge drying workshop as an example.

[0028] 1. The sludge treatment capacity of this project is 200kg / h, and the properties of the sludge entering the equipment system are shown in Table 1:

[0029] Feed sludge properties table

[0030] project Mass fraction % Remark moisture content 80.6 Take the average value based on the test data of one month Solid content 19.4 Take the average value based on the test data of one month

[0031] Table I

[0032] 2. Please refer to Table 2 for the main equipment list of the project:

[0033] Table II List of main equipment

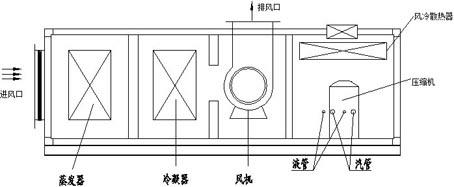

[0034] serial number name Model / parameter quantity 1 Sludge drying chamber SW-200 1 set 2 fan Z10-20 1 set 3 Activated carbon adsorption device HXF-10 1 set 4 Evaporator Copper tube with aluminum fin tube ...

Embodiment 2

[0042] In the following, a specific description will be given by taking the application of the present invention in a sludge drying workshop as an example.

[0043] 1. The sludge treatment capacity of this embodiment is 12000kg / day, and the properties of the sludge entering the equipment system are shown in Table 4:

[0044] project Mass fraction % Remark moisture content 78.5 Take the average value based on the test data of one month Solid content 21.5 Take the average value based on the test data of one month

[0045] Table four

[0046] 2. Please refer to Table 5 for the main equipment list of the project:

[0047] List of main equipment

[0048] serial number name Model / parameter quantity 1 Sludge drying chamber SW-500 1 set 2 fan Z10-30 1 set 3 Activated carbon adsorption device HXF-30 1 set 4 Evaporator Copper tube with aluminum fin tube 1 set 5 condenser Copper tube with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com