Method for preparing humidity-adjusting material from loess or sepiolite

A humidity-conditioning material and a technology of sepiolite, which is applied in the field of preparing humidity-conditioning materials by using loess or sepiolite, can solve the problems of affecting humidity-conditioning performance and destroying porous structures, and achieve the effects of reducing usage and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

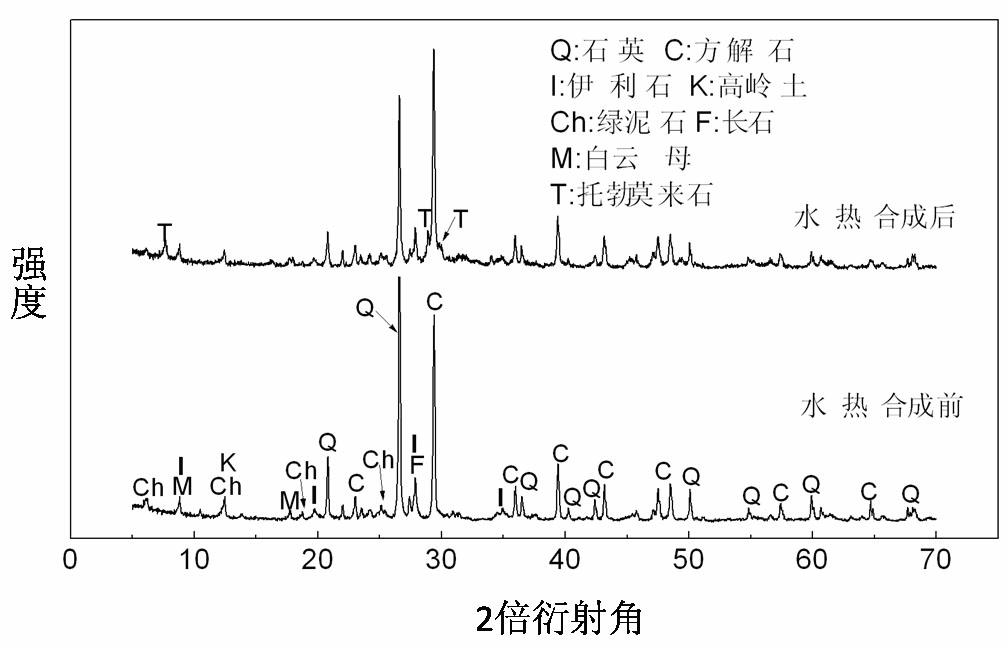

Embodiment 1

[0026] First, select loess as the main raw material, select industrial slaked lime as the auxiliary raw material, mix the above raw materials so that in the mixture, slaked lime accounts for 18% by weight; then, add water accounting for 10% of the total weight of the mixture to the above mixture , after stirring evenly, press and form under the tablet machine, the forming pressure is 30MPa; finally, put the pressed sample into the hydrothermal reaction kettle, hydrothermally treat at 200℃, 1.55MPa saturated steam pressure for 12h, and then dry Finally, the final sample was obtained, and its flexural strength was 26.8MPa.

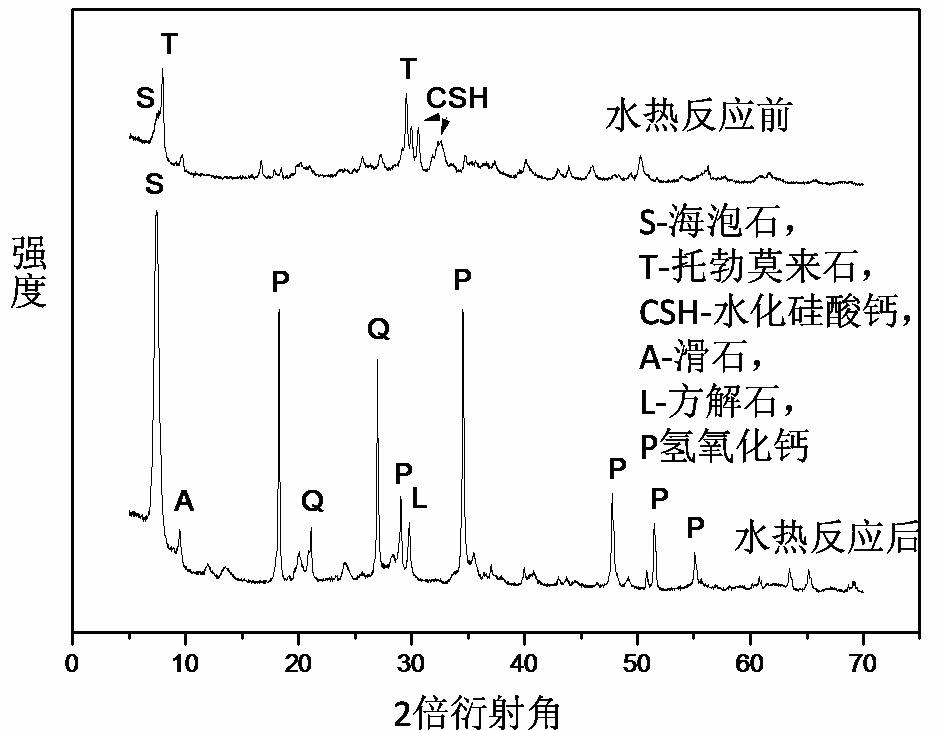

Embodiment 2

[0028] First, select sepiolite as the main raw material, select industrial slaked lime as the auxiliary raw material, mix the above raw materials so that the mass of slaked lime in the mixture accounts for 28%; then, add water accounting for 30% of the total weight of the mixture to the above mixture , after stirring evenly, press molding under the tablet press, the molding pressure is 30MPa; finally, put the pressed sample into the hydrothermal reaction kettle, and hydrothermally treat it at 200°C and 1.55MPa saturated steam pressure for 12h to obtain the final The sample has a flexural strength of 16.8MPa.

Embodiment 3

[0030] First, the final samples obtained in Examples 1 and 2 were selected as experimental samples. The constant temperature and humidity box was set at a temperature of 25°C and a relative humidity of 75%, and the relative humidity in the airtight box was controlled to 75% by saturated saline solution. After reaching stability, put the final sample into the sample rack tray in the airtight box quickly, record the weight change of the sample every 10 minutes, and measure the change within 24 hours; then, compare the relative humidity in the constant temperature and humidity box and the airtight box Adjusted to 33% (adjusted by replacing the saturated salt solution in the airtight box), and then kept for 24 hours, and the weight change of the sample was recorded during the process. So far, the curve of the amount of moisture absorption and desorption of the sample in a humidity change cycle as a function of time can be obtained, that is, the characteristics of the material for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com