Process for deoxidizing and dehydrating tetrachloroethylene and equipment for process

A tetrachloroethylene and process technology, applied in the field of tetrachloroethylene treatment, can solve the problems of unreachable, low purity, poor chromaticity, etc., and achieve the effects of good chromaticity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A perchlorethylene deoxygenation and dehydration process comprises the following steps:

[0044] (1) Send the perchlorethylene to be prepared into the raw material tank V101, and the detection and laboratory indicators include chromaticity, purity, moisture, and pH value;

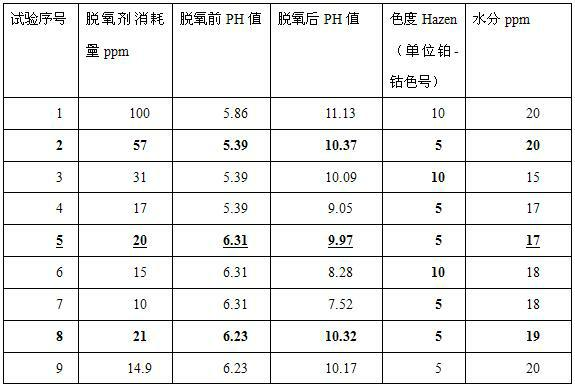

[0045] (2) According to the test results, use 5A molecular sieve when the moisture is 70-80 ppm, use 4A molecular sieve when the moisture is 60-70ppm, and use 3A molecular sieve when the moisture is 50-60ppm; when the pH value is 2-3, use about 3mm alkaline carbon to deoxidize When the pH value is 3-4, use about 4mm alkaline carbon oxygen scavenger, and when the pH value is 4-5, use about 5mm alkaline carbon oxygen scavenger; if the moisture is 70-80ppm, when the pH is 2-3, The mass ratio of oxygen scavenger to molecular sieve is 1: 9.5; in other cases, the mass ratio of oxygen scavenger to molecular sieve is 1: 10;

[0046] (3) Start the feed pump P101A, send tetrachlorethylene into the deoxygenation...

Embodiment 2

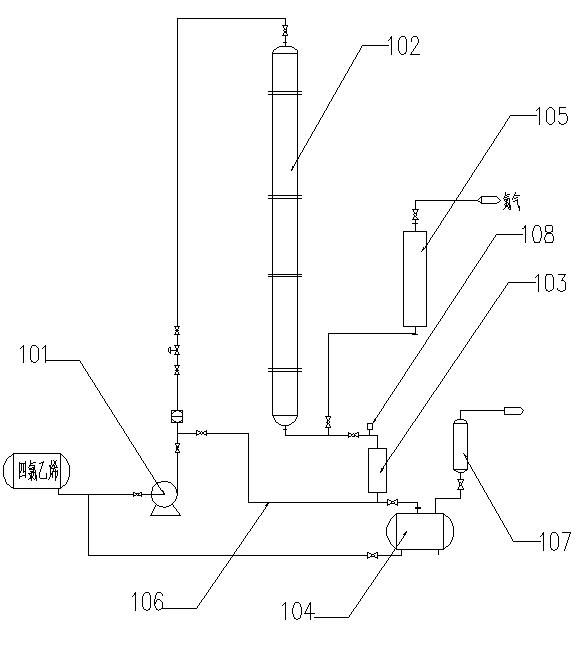

[0055] Such as figure 1 and 2 Shown, a kind of equipment that is used for the perchlorethylene deoxygenation drying process of above-mentioned embodiment 1, comprises the feed pump 101 that communicates successively, deoxygenation drying tower 102, filter 103 and finished product tank 104;

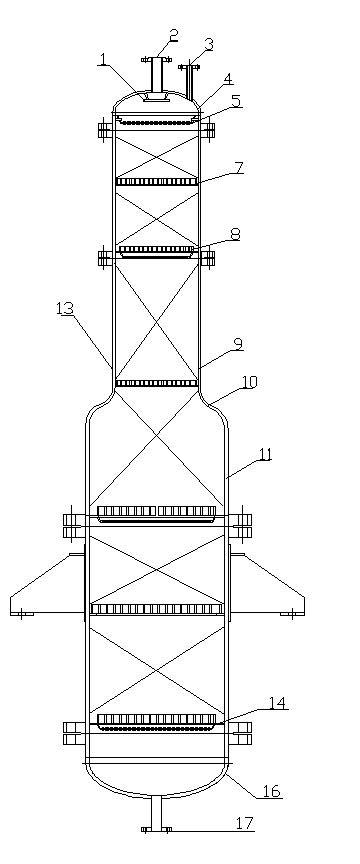

[0056] Described deoxygenation drying tower comprises tower body 13, and the upper and lower ends of described tower body 13 are respectively provided with upper head 4 and lower head 16; Described tower body 13 is divided into upper, middle and lower three sections, each Sections were filled with basic filler basic carbon and molecular sieve Al 2 o 3 , layered in a ratio of 4:3; the bottom and middle of the tower body 13 are respectively provided with filler support grids, and the upper tower body 6 is provided with an alkaline filler baffle 7 and a molecular sieve filler baffle 8, and the upper layer Fill the basic packing, and the molecular sieve packing in the lower layer; the packi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com