Extract of willow barks or willow branches and method for preparing salicin

A salicin and extract technology, applied in the field of chemical engineering, can solve the problems of large consumption of organic solvents, environmental hazards of organic reagents, and high cost, and achieve the effects of easy industrialization, cost reduction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

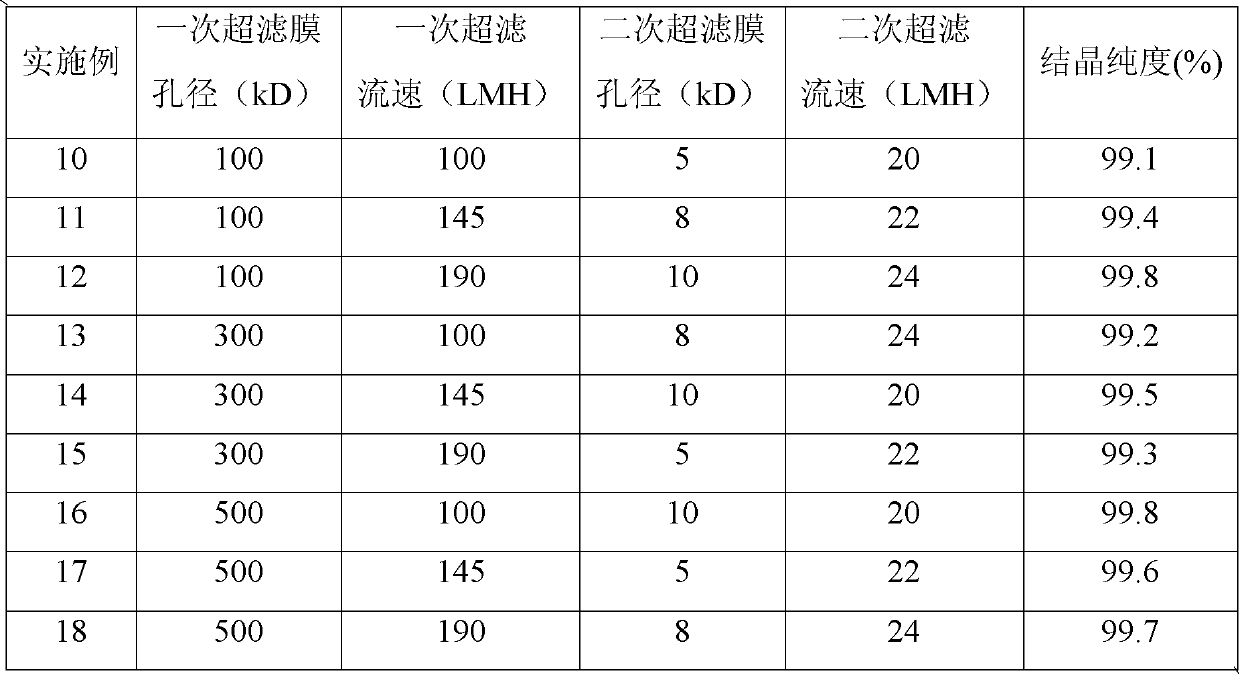

[0032] The invention provides a method for preparing extracts from willow bark or willow branches and further refining salicin, specifically water extraction, ultrafiltration, adsorption separation (or decolorization after adsorption separation) and crystallization to obtain water Products with higher salicin content.

[0033] If the extract of willow bark or willow branch is prepared, it is only necessary to obtain a product with a salicin content of 40-60%, the following method can be used:

[0034] A, using willow bark or willow branches as raw materials, extracted with water;

[0035] B, filter the extract;

[0036] C, the filtrate is separated by resin adsorption;

[0037] D. crystallization;

[0038] It is characterized in that: step B is filtered by ultrafiltration: the extract is first passed through a 100-500kD ultrafiltration membrane, and then passed through a 5-10kD ultrafiltration membrane, and the average membrane flux is controlled at 100-190LMH and 20-24LMH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com