Carving gravure printing ink applicable to non-absorbent printed material and connecting materials of carving gravure printing ink

A technology of gravure ink and connecting material, applied in the direction of ink, application, household appliances, etc., can solve the problem of not adapting to non-absorbent substrates, etc., and achieve the effect of clear lines and full graphics and text

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

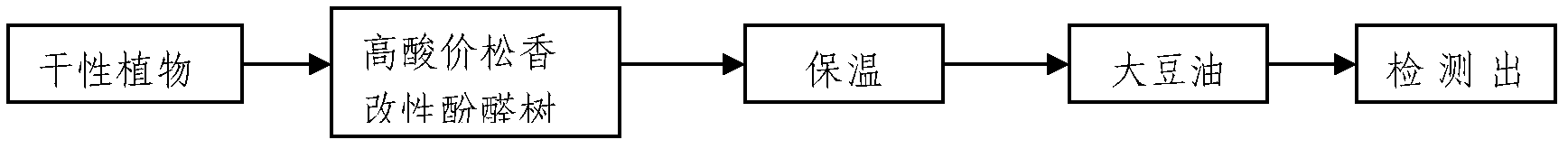

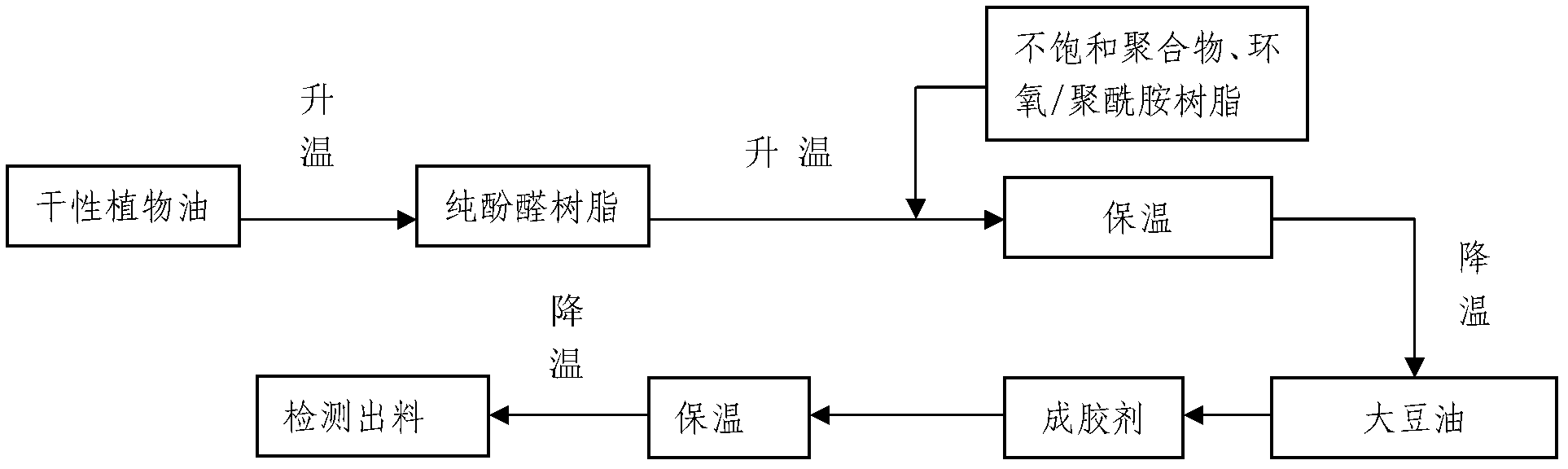

Method used

Image

Examples

example 3

[0059] Binder B formula example 3 (by weight):

[0060] material name

number of copies

45

Tung oil

12

Pure phenolic resin

40

[0061] polybutadiene

2

Gelling agent

1

[0062] The technical indicators of the connecting material B are as follows: viscosity 10-14PaS / 40℃.

[0063] The unsaturated polymer may be a low molecular weight polymer such as polybutadiene, polyisoprene, poly-1,3 hexadiene, or a copolymer of two of them. Polybutadiene is recommended.

[0064] The phenol used in the phenolic resin can be selected from one of phenol, bisphenol A, butanol etherified cresol, p-tert-butylphenol, p-octylphenol, p-tert-octylphenol, p-nonylphenol or p-dodecylphenol Or multiple mixed use, it is recommended to use p-nonylphenol formaldehyde phenolic resin.

[0065] The phenol used in high acid value rosin modified phenolic resin can be selected from phenol, bisphenol A, butano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com