Novel lubricating material, preparation method thereof and application thereof

A lubricating material and a new type of technology, applied in the field of materials, can solve the problems of easy separation and precipitation, non-abrasive wound repair, high thermodynamic and kinetic conditions, etc., and achieve simple preparation method, easy operation, and improved friction reduction and anti-wear The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

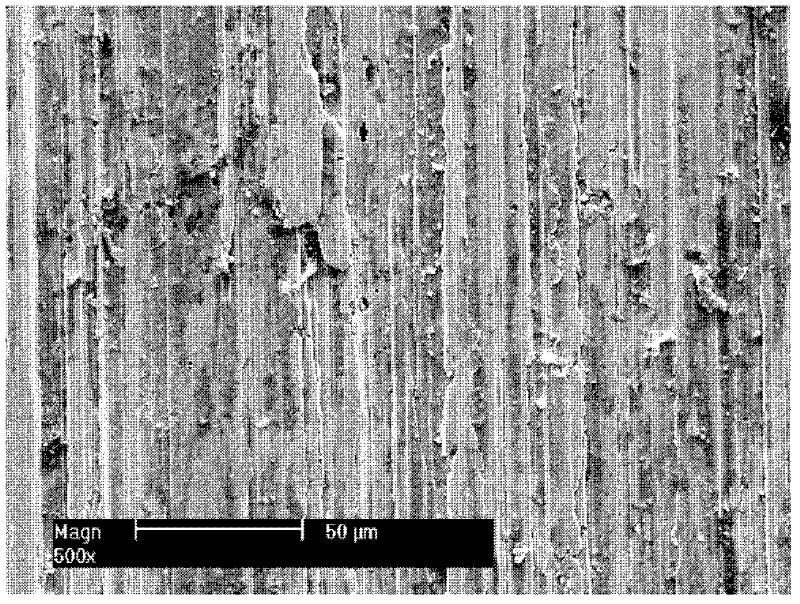

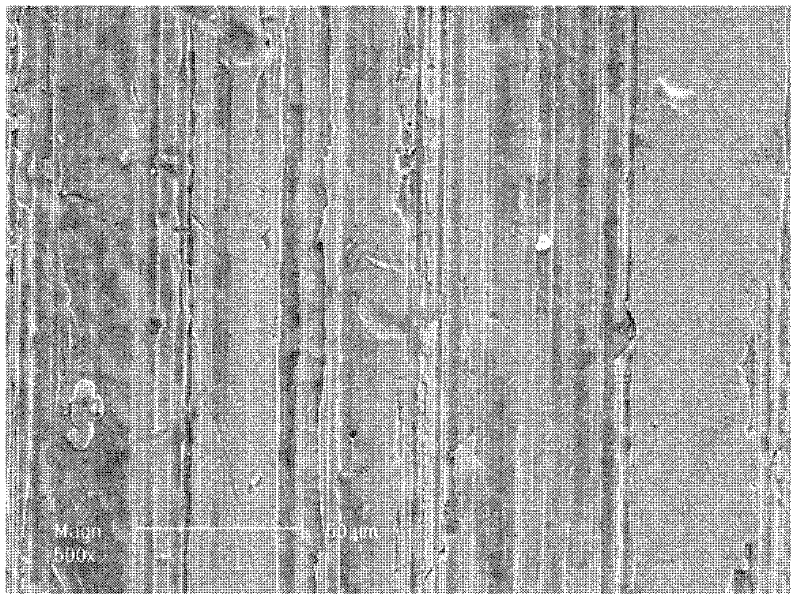

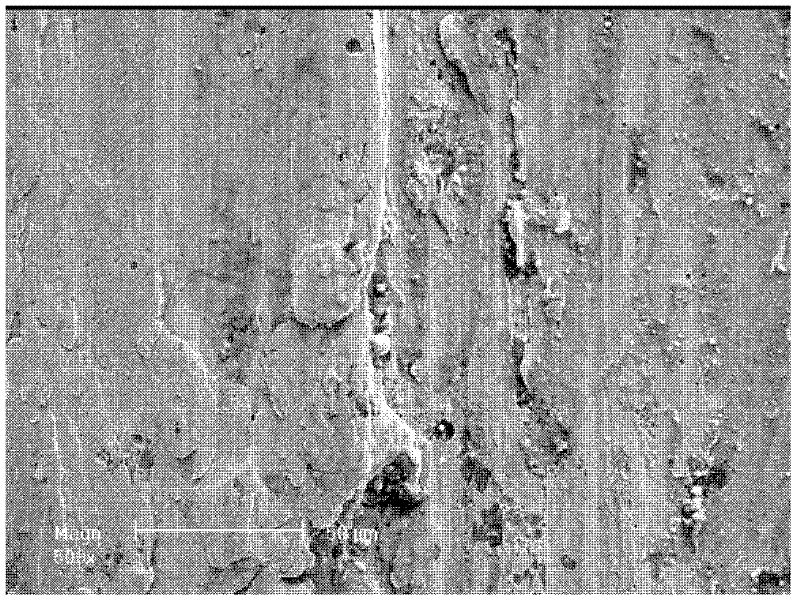

Image

Examples

Embodiment Construction

[0020] The following non-limiting examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way. Unless otherwise specified, the ultrasonic generator used in the present invention is Shanghai Zhixin Instrument Co., Ltd., model DL-60D.

[0021] Among the raw materials used in the present invention, lubricating oil (SF / CD 15W / 40) comes from Dalian Petrochemical. Sepiolite comes from Henan Nanyang Leibao Sepiolite Processing Co., Ltd.; Actinolite comes from Anhui Haozhou Hongtai Pharmaceutical Co., Ltd.; Kaolinite comes from Yingkou Qihe Powder Industry Co., Ltd.; Serpentine comes from from Jiangsu Longteng Chemical Co., Ltd.; tremolite comes from Xinhui Mining Fiber Factory, Lingshou County, Hebei; dolomite comes from Anhui Chizhou Tiejiachong Mining Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com