Equipment For Preparing Zinc Selenide/zinc Sulfide Optical Material, Furnace, Heater For The Furnace

A technology of optical materials and heating bodies, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve problems such as complex structures of heating bodies, and achieve good thermal performance and mechanical properties, high transmission characteristics, optical properties, etc. The effect of high performance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0031] The technical solution prototype of this device is derived from the Russian Federation №2163943 (publication number) patent. The prototype of the furnace body and heater selected for the equipment in the new technology solution is derived from the Russian Federation №47895 (publication number) patent.

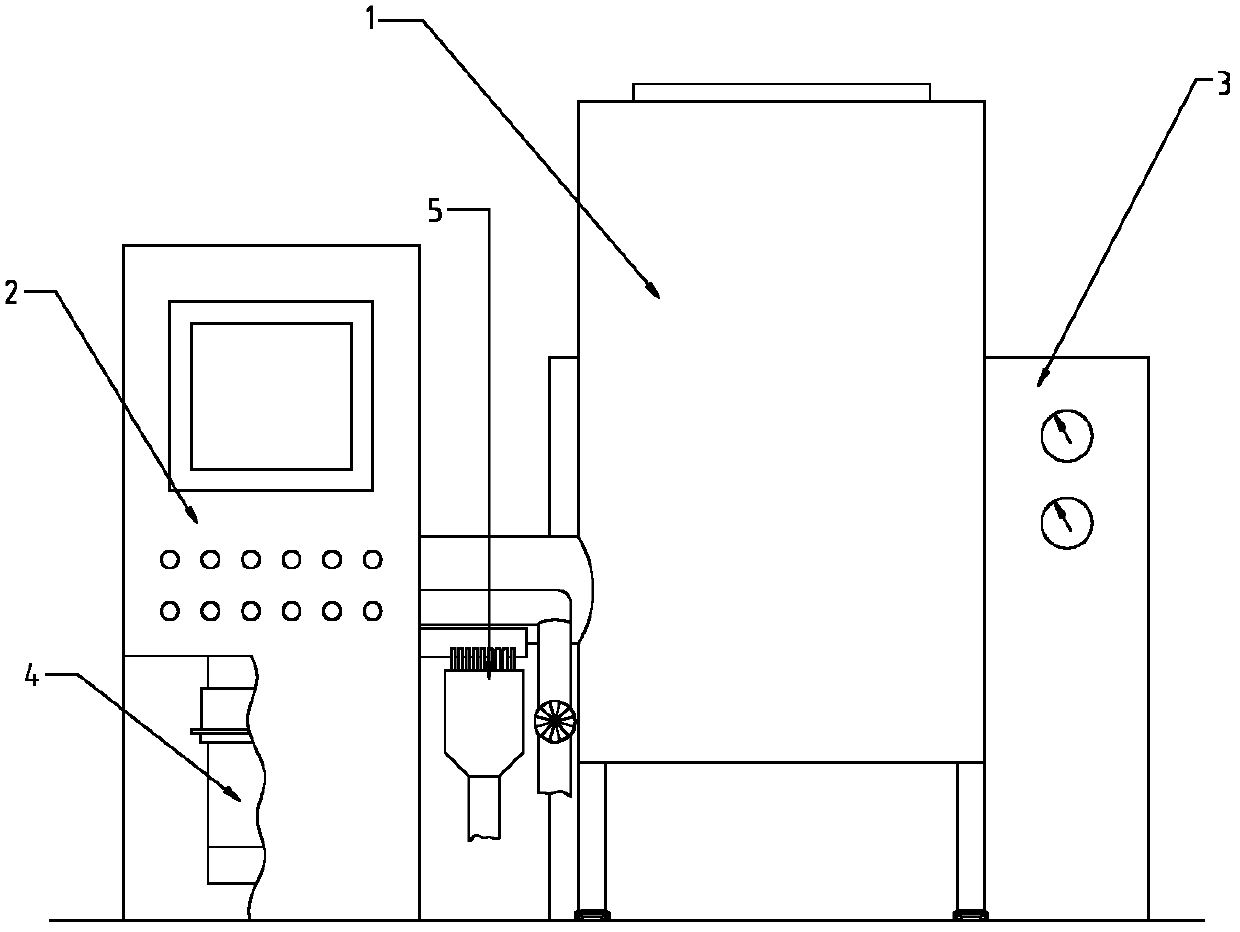

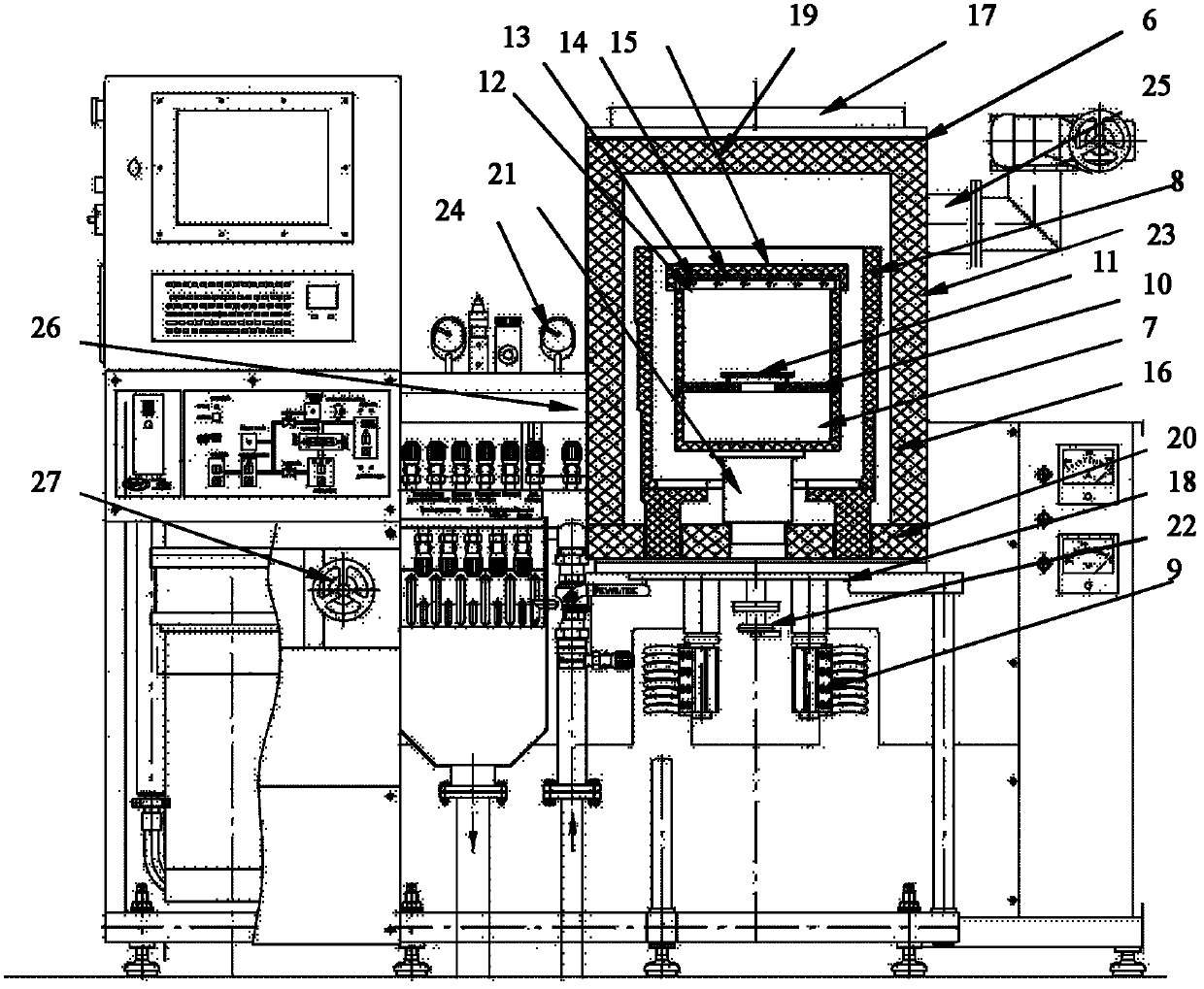

[0032] The equipment used to make zinc selenide / zinc sulfide synthetic optical materials includes furnace, control system, vacuum system, water cooling system and control power supply. Similarly, the control panel is connected with the water cooling system (the water cooling system is connected with the vacuum system) through the control power supply.

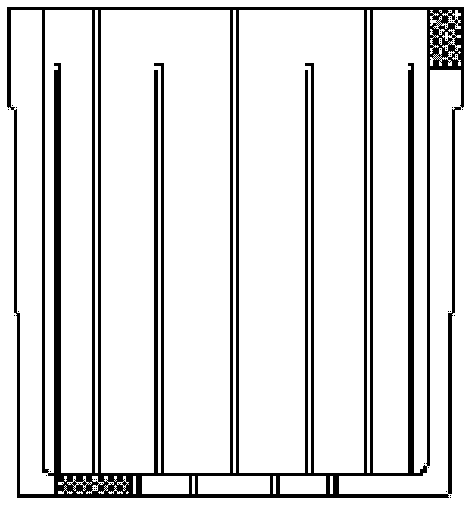

[0033] The furnace used to grow zinc selenide / zinc sulfide composite optical materials is a cylindrical structure with a heating body installed inside. The heating body is a strip-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com