Main motor of rapier loom

A technology of rapier loom and main motor, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of unsatisfactory driving mode, manual replacement of pulleys, motor drive chain length, etc. The effect of reducing energy consumption and shortening the transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

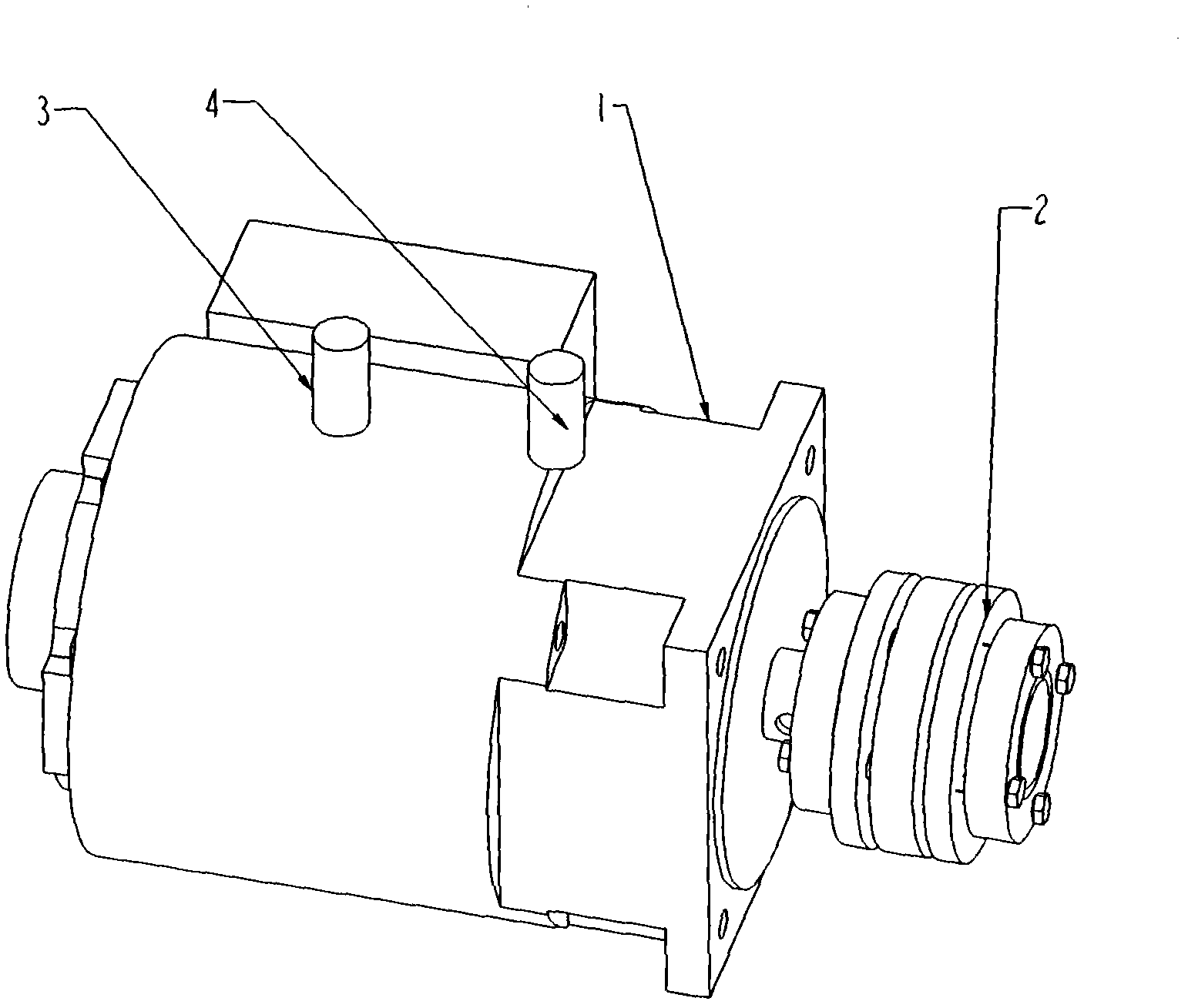

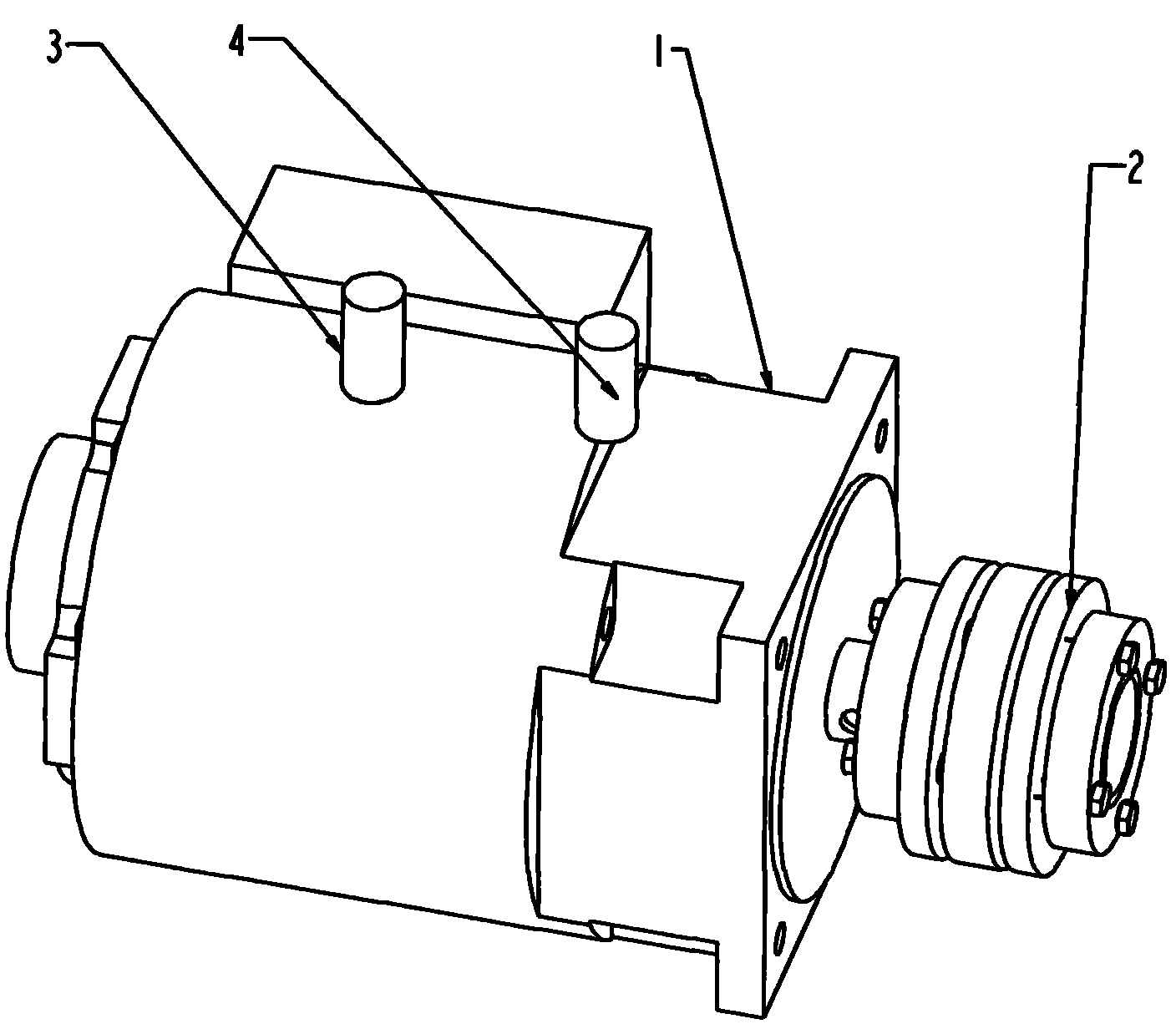

[0007] A main motor of a rapier loom, such as figure 1 As shown, the main motor is an oil-cooled servo motor 1, the output shaft of the oil-cooled servo motor 1 is provided with a diaphragm coupling 2, and the oil-cooled servo motor 1 is provided with a cooling oil inlet joint 3, a cooling oil Oil outlet joint 4. The oil-cooled servo motor 1 is installed at the position of the original clutch of the rapier loom, the belt and the clutch part are eliminated, and the output shaft of the motor is connected with the main shaft through the diaphragm coupling 2 to directly drive the main shaft to run. The oil-cooled servo motor 1 is directly driven, and the main motor stops at the same time when the machine stops, which effectively reduces energy consumption. The direct drive of the servo motor makes the structure of the loom compact, and the speed of the loom can be changed during operation according to different types of yarn raw materials and operation requirements, which improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com