Production method of zero-emission and full-environment-friendly synthetic leather

A manufacturing method and technology for synthetic leather, applied in the field of synthetic leather manufacturing, can solve problems such as environmental pollution, and achieve unique visual and feel effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

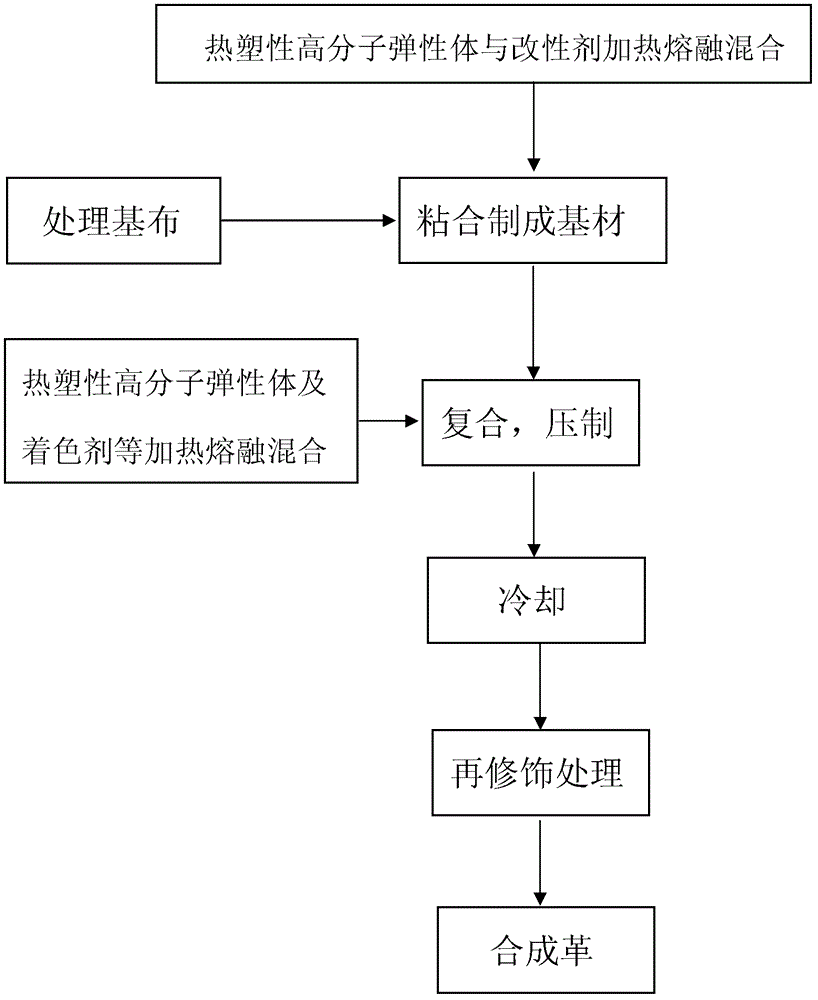

[0022] A kind of manufacturing method of zero-emission full-environmental protection synthetic leather, as attached figure 1 shown. Follow the steps below in order:

[0023] A. Coat water-based acrylic on one side of the base fabric with non-woven fabric at 100°C, and dry and harden at 120°C;

[0024] B. Heat 0.7 parts by weight of thermoplastic elastomer TPE and 0.3 parts by weight of modifier through an extruder to melt and mix them at 90°C. Then through the die head and the base cloth treated in step A, bond under the pressure of 0.5 MPa to make a strong base material.

[0025] C. Mix 1 part by weight of thermoplastic elastomer TPE, 0.2 part by weight of color masterbatch, and 0.8 part by weight of silicone oil evenly. After being heated by an extruder at 100°C and melted, it is extruded from a die through a roller with texture. compound under pressure. Made a preliminary synthetic leather.

[0026] D. The preliminary synthetic leather is strengthened in 30°C water, an...

Embodiment 2

[0030] A kind of manufacturing method of zero-emission full-environmental protection synthetic leather, as attached figure 1 shown. Follow the steps below in order:

[0031] A. Apply water-based acrylic to one side of the base fabric with nylon fabric at 160°C, and dry and harden at 150°C;

[0032] B. Heat 1 weight part of thermoplastic elastomer TPE and 0.5 weight part of modifier through an extruder to melt and mix them at 350°C. Then through the die head and the base cloth treated in step A, bond under a pressure of 0.8 MPa to form a strong base material.

[0033] C. Mix 1 part by weight of thermoplastic elastomer TPE, 0.2 part by weight of color masterbatch, and 0.8 part by weight of polyethylene, heat and melt at 350 °C in an extruder, and then extrude from a die through a roller with texture, at 0.5 Composite under MPa pressure. Made a preliminary synthetic leather.

[0034] D. The preliminary synthetic leather is strengthened in 50°C water, and dried to remove wate...

Embodiment 3

[0037] A kind of manufacturing method of zero-emission full-environmental protection synthetic leather, as attached figure 1 shown. Follow the steps below in order:

[0038] A. Apply water-based EVA glue on one side of the polyester woven fabric as the base fabric at 200°C, and dry and harden at 100°C;

[0039] B. Melt and mix 0.6 parts by weight of thermoplastic polyurethane elastomer TPU and 0.2 parts by weight of modifier through an extruder at 80°C, and then pass through the die and the base cloth treated in step A under a pressure of 0.3MPa. Synthesized into a strong base material.

[0040] C. Mix 0.8 parts by weight of thermoplastic elastomer TPE, 3 parts by weight of toner, and 0.8 parts by weight of silicone oil evenly, heat and melt at 260°C in an extruder, extrude through a die, and press with a roller with texture at a pressure of 0.3 MPa Composite below. Made into preliminary synthetic leather.

[0041] D. The preliminary synthetic leather is strengthened in 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com