Flocculating agent injecting and adding device for internal soft silt layer of silt storage yard or fill area

A technology of silt storage yard and adding device, which is applied in soil protection, construction, infrastructure engineering and other directions, can solve the problem of small drilling machinery being difficult to enter the site, etc., and achieve the effect of simple structure, improved uniformity and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

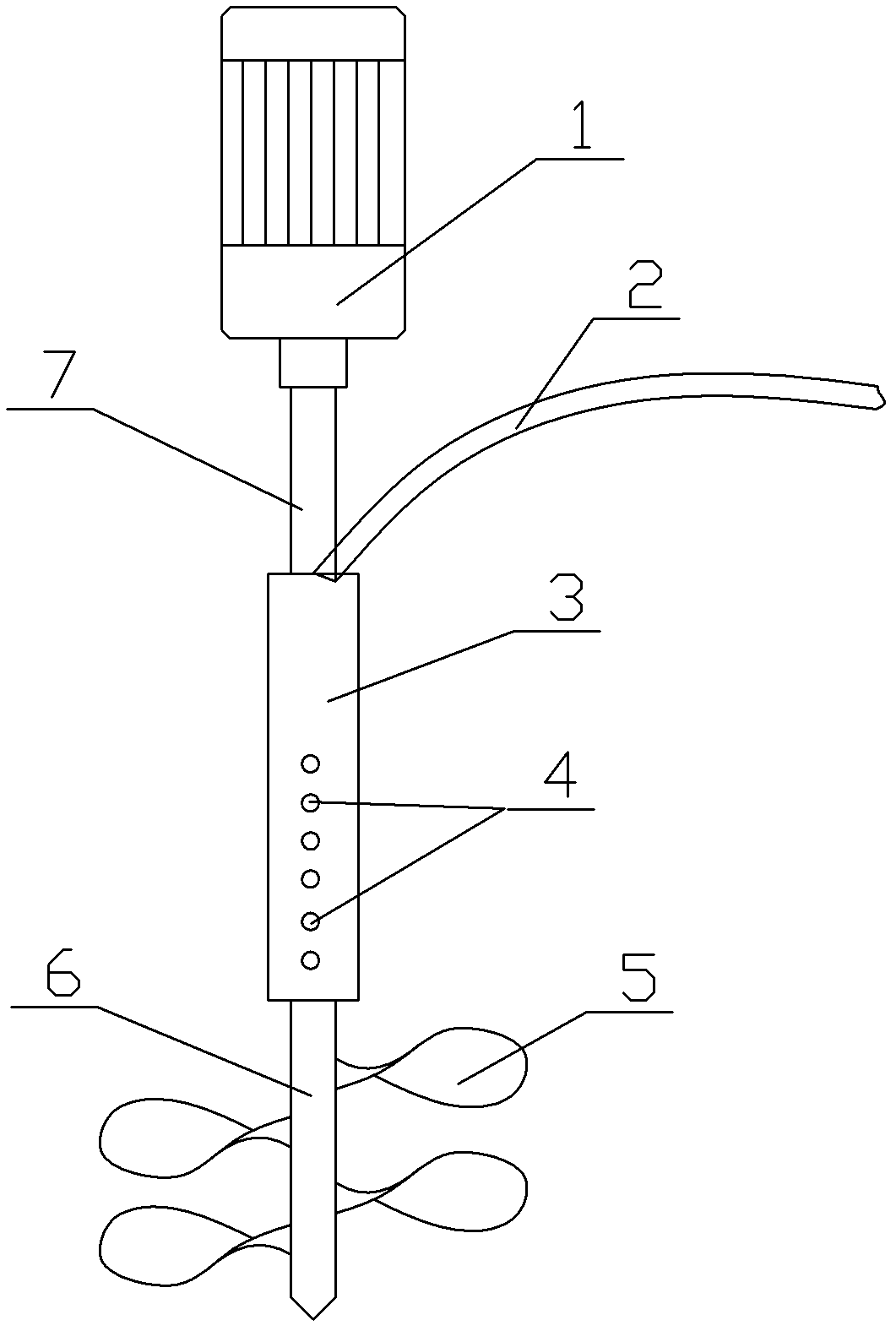

[0011] See figure 1 , a flocculant pressure injection adding device for the thin soft mud layer inside a sludge stockyard and a dredging reclamation site, comprising a motor 1, a stirring rod 7, a stirring head and a flocculant filling sleeve 3.

[0012] The stirring head includes a stirring shaft 6 affixed to the lower end of a stirring rod 7 , and the stirring shaft 6 is provided with multi-layered propeller blades 5 . Each layer of propeller blades 5 is welded on the stirring shaft 6 in order from top to bottom. The stirring shaft 6 preferably adopts a hollow structure, which is light in weight and easy to operate; the lower end of the stirring shaft 6 is preferably an inverted conical shape to facilitate operation and use.

[0013] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com