Hydraulic power shock excitation equipment for building foundation pile

A hydraulic power and vibration-exciting technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of difficulty in quality improvement, difficulty in ensuring the center of the falling hammer, and shortening the time of lifting the hammer, so as to save manpower and improve lifting efficiency. The effect of fast speed and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

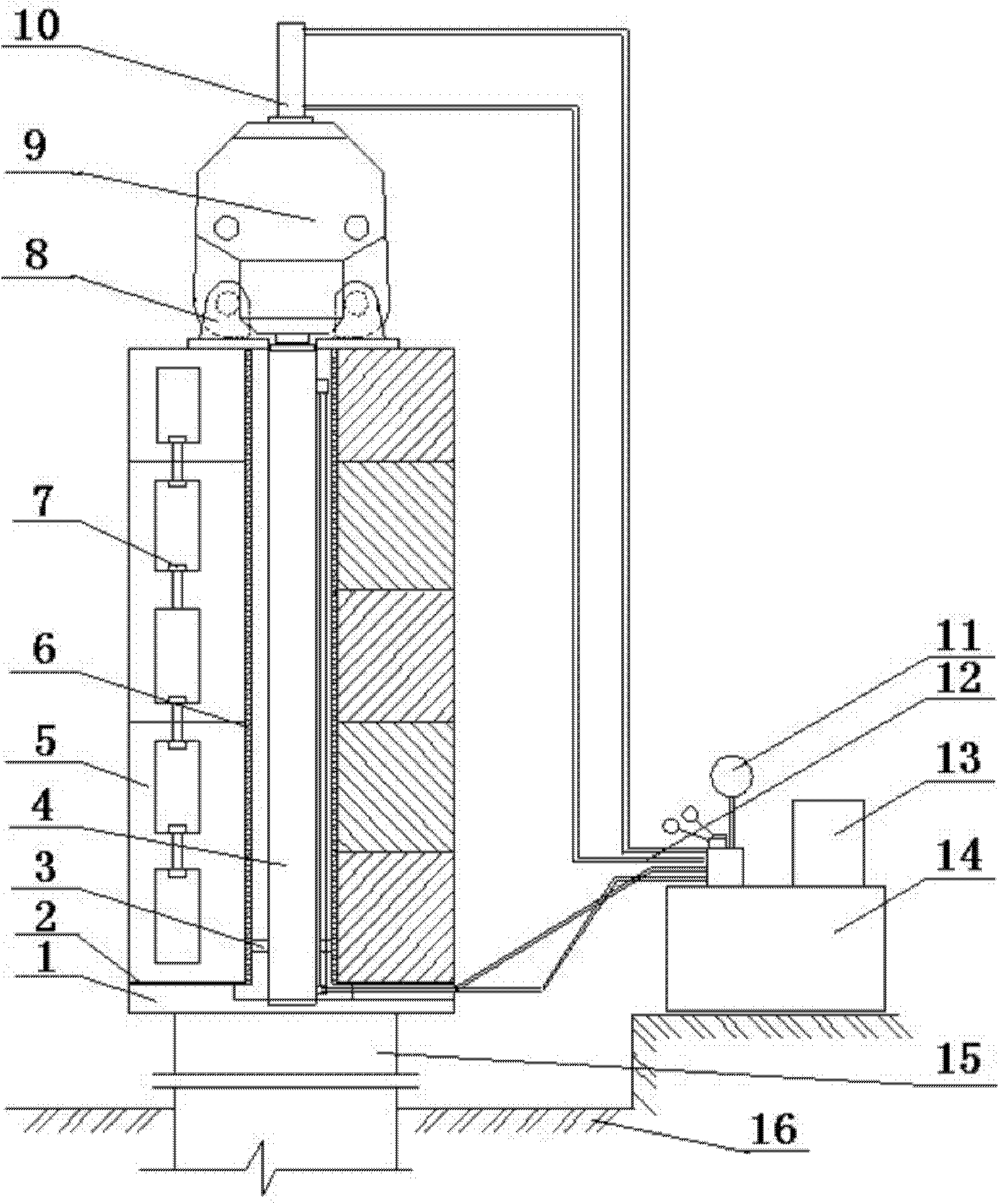

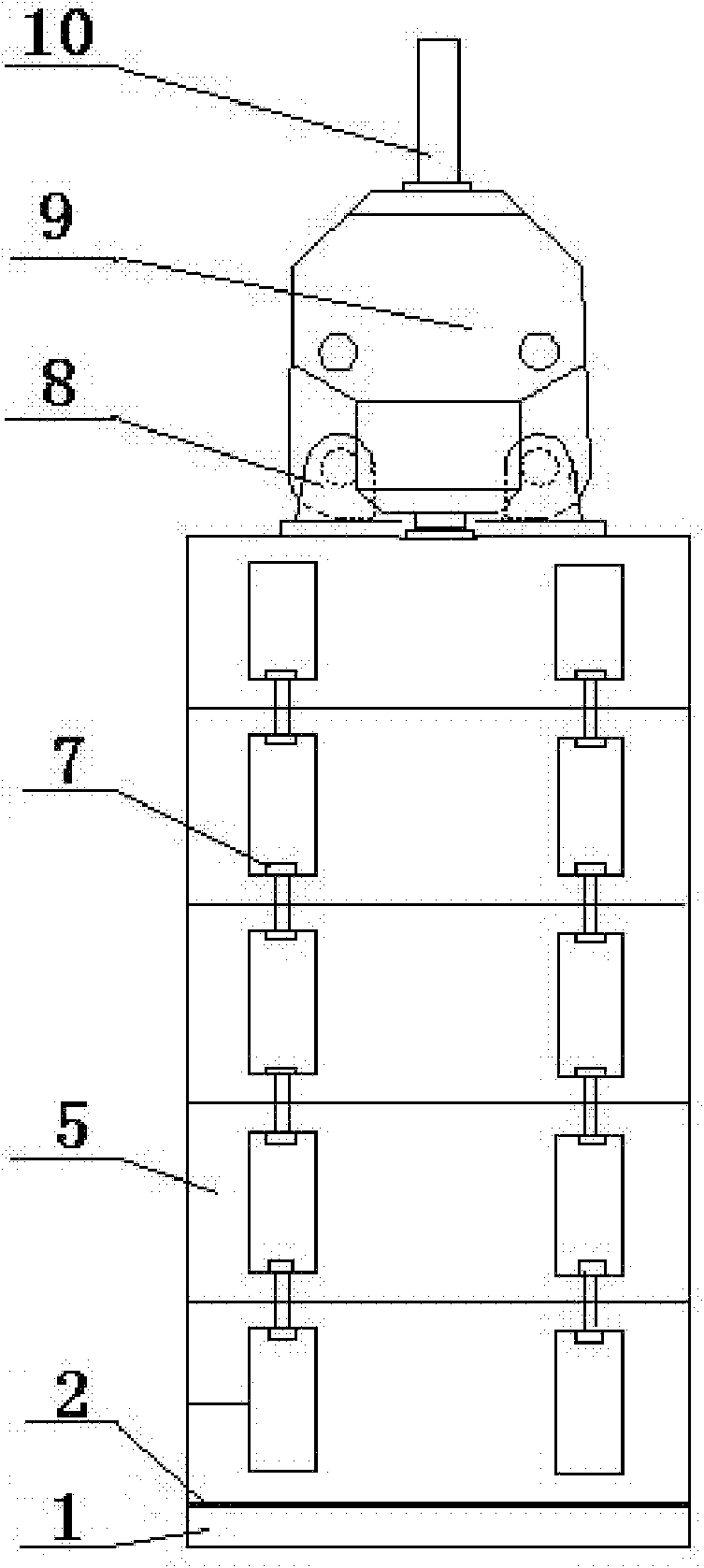

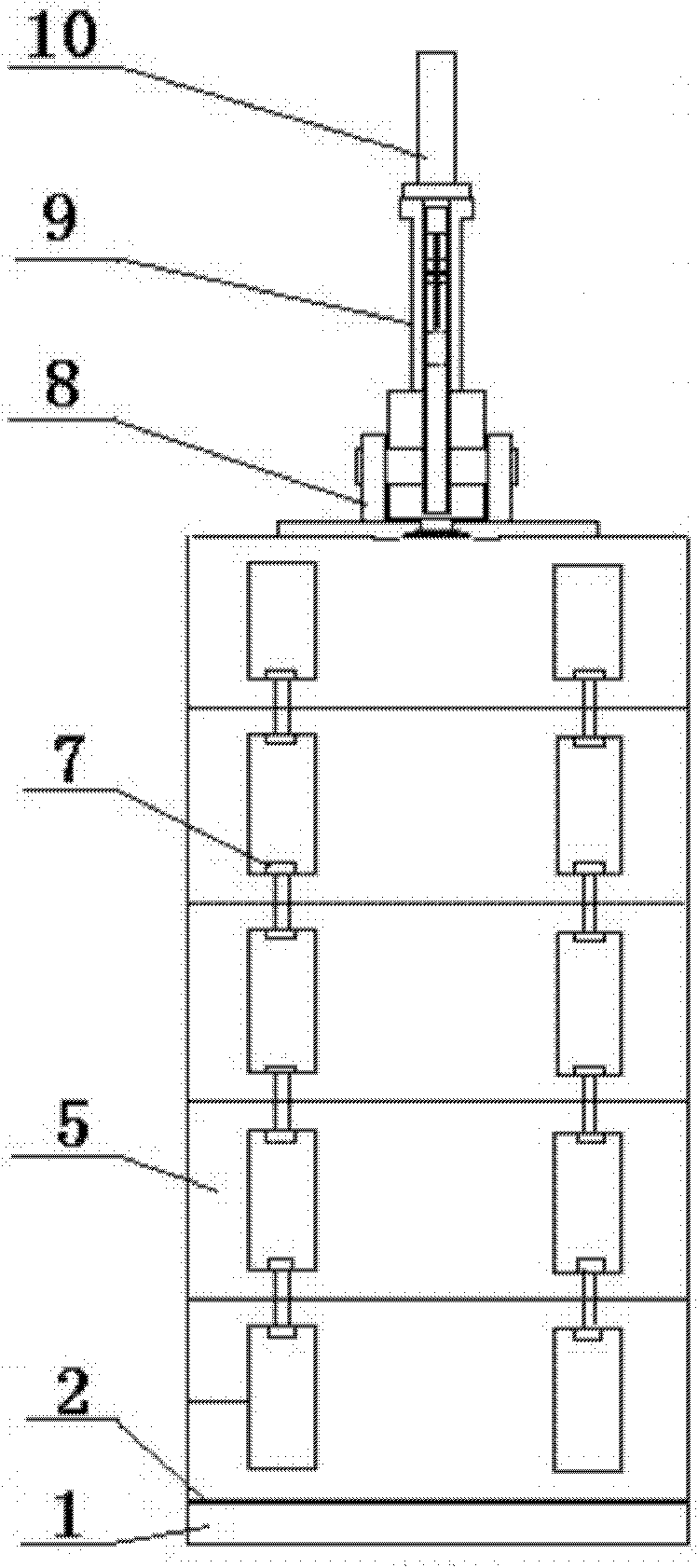

[0026] Specific embodiments of the present invention, such as Figure 1-7 As shown, a construction foundation pile hydraulic power vibration excitation equipment includes a base 1, a vibration damping pad 2, a dynamic vibration excitation part and a hook part, wherein the dynamic vibration excitation part is arranged on the base 1 and the vibration damping pad 2, and the power The upper part of the vibration excitation part is the hook part, which is characterized in that: the power vibration excitation part is composed of a hydraulic transmission power vibration excitation mechanism and a hydraulic pump station part, wherein the hydraulic transmission power vibration excitation mechanism consists of a hydraulic cylinder assembly and a dynamic hammer assembly The hydraulic cylinder assembly is located in the middle of the moving hammer assembly. The hydraulic cylinder assembly is composed of a hydraulic cylinder support 3, a hydraulic cylinder 4, and a hydraulic cylinder sheath ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com