Full-environment-friendly chloride-free polyvinyl chloride floor and production method thereof

A kind of stone plastic floor, environmental protection technology, applied in the direction of building, building structure, floor, etc., can solve the problems of degradation, environmental pollution, etc., to achieve the effect of good thermal performance, good chemical resistance, excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

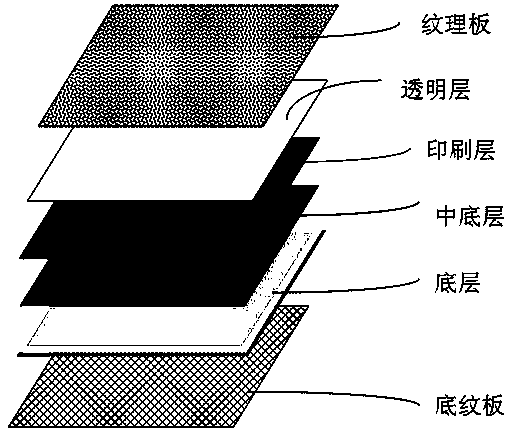

Image

Examples

Embodiment 1

[0042] The all-environmental chlorine-free stone-plastic floor is characterized in that: the stone-plastic floor is composed of a wear-resistant layer, a printing layer, an A sheet and a B sheet;

[0043] The raw material of described A tablet and the mass percent of each raw material are:

[0044] TPU mixed particles 20%

[0045] Ethylene methyl acrylate copolymer 8%

[0046] Polyhydroxyalkanoate 2%

[0048] Petroleum resin 1%

[0049] Reinforced filler material 60%

[0050] Antioxidant and light stabilizer 0.2%;

[0051] The raw material of described B tablet and the mass percent of each raw material are:

[0052] TPU mixed particles 10%

[0053] Ethylene methyl acrylate copolymer 15%

[0054] Polyhydroxyalkanoate 3%

[0055] Acrylate copolymer 2%

[0056] Petroleum resin 3%

[0057] Reinforcing filler material 55%

[0058] Antioxidants and light stabilizers 0.2%.

[0059] The reinforcing filling material is calcite or kaolin.

[00...

Embodiment 2

[0073] The all-environmental chlorine-free stone-plastic floor is characterized in that: the stone-plastic floor is composed of a wear-resistant layer, a printing layer, an A sheet and a B sheet;

[0074] The raw material of described A tablet and the mass percent of each raw material are:

[0075] TPU mixed particles 30%

[0076] Ethylene methyl acrylate copolymer 8%

[0077] Polyhydroxyalkanoate 2%

[0078] Acrylate copolymer 3%

[0079] Petroleum resin 1%

[0080] Reinforcing filler material 50%

[0081] Antioxidant and light stabilizer 0.2%;

[0082] The raw material of described B tablet and the mass percent of each raw material are:

[0083] TPU mixed particles 20%

[0084] Ethylene methyl acrylate copolymer 15%

[0085] Polyhydroxyalkanoate 3%

[0086] Acrylate copolymer 2%

[0087] Petroleum resin 3%

[0088] Reinforcing filler material 45%

[0089] Antioxidants and light stabilizers 0.2%.

[0090] The reinforcing filling material is calcite or kaolin.

...

Embodiment 3

[0104] The all-environmental chlorine-free stone-plastic floor is characterized in that: the stone-plastic floor is composed of a wear-resistant layer, a printing layer, an A sheet and a B sheet;

[0105] The raw material of described A tablet and the mass percent of each raw material are:

[0106] TPU mixed particles 20%

[0107] Ethylene methyl acrylate copolymer 10%

[0108] Polyhydroxyalkanoate 2%

[0109] Acrylate copolymer 3%

[0110] Petroleum resin 1%

[0111] Reinforcing filler material 50%

[0112] Antioxidant and light stabilizer 0.2%;

[0113] The raw material of described B tablet and the mass percent of each raw material are:

[0114] TPU mixed particles 10%

[0115] Ethylene methyl acrylate copolymer 20%

[0116] Polyhydroxyalkanoate 3%

[0117] Acrylate copolymer 2%

[0118] Petroleum resin 3%

[0119] Reinforcing filler material 45%

[0120] Antioxidants and light stabilizers 0.2%.

[0121] The reinforcing filling material is calcite or kaolin.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com