Drilling rig with following pipe pile and construction method for following pipe pile

A technique of following pipes while drilling and drilling rigs, which is applied in the direction of drilling equipment and methods, sheet pile walls, drilling equipment, etc., and can solve the problems of insufficient bearing capacity of high-strength prestressed pipe piles, noise pollution, and limited application range, etc. problem, to achieve the effect of pile positioning and follow-up speed control, compact structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

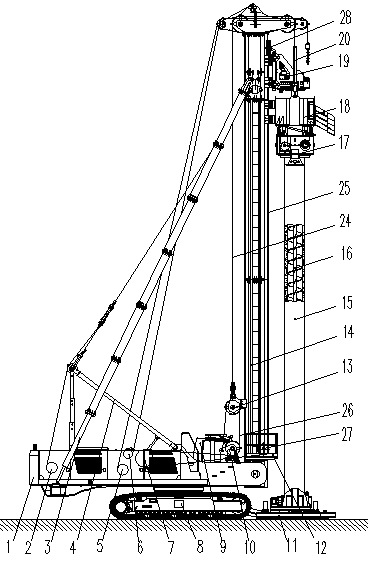

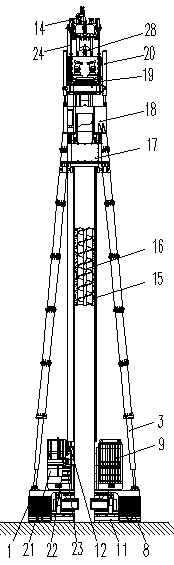

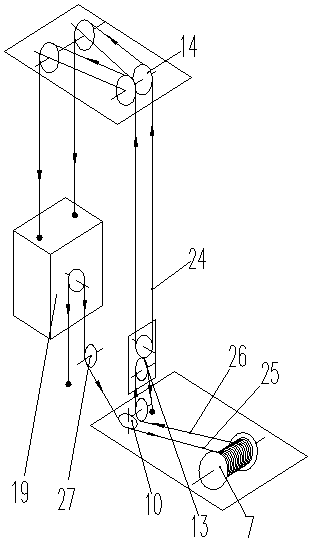

[0048] see figure 1 , figure 2 with Image 6 , the composition of the MWD drilling rig includes a crawler chassis 8; a platform 1 located on the chassis 8, a cab 9 located on the platform 1, a power system 21, a hydraulic system 22 and a control system 23; a column installed on the platform 1 14 and the support rod 3; the cylinder base is fixedly connected to the lower end of the support rod 3, and the piston rod is hinged with the ball head of the platform 1 to adjust the vertical oil cylinder; the vertical frame winch 2 on the platform 1 is used for erecting and laying down the column 14; The power head 19 that can slide along the column 14, the dump box 18 that is positioned at the power head 19 below; The auger rod assembly 16 that is connected with the power head 19; The reamer bit 30 that is positioned at the auger rod assembly 16 lower ends; 29 connect the exciter 17 below the soil discharge box 18; the power head 19, the soil discharge box 18 are connected together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com