Fully-unloaded gear shifting device

A second gear, active technology, applied in the direction of transmission, transmission control, components with teeth, etc., can solve the problems of difficult repair, disengagement, flameout, difficult to achieve reverse gear, etc., and achieve simple and novel structure, reliable shifting Blocking function, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

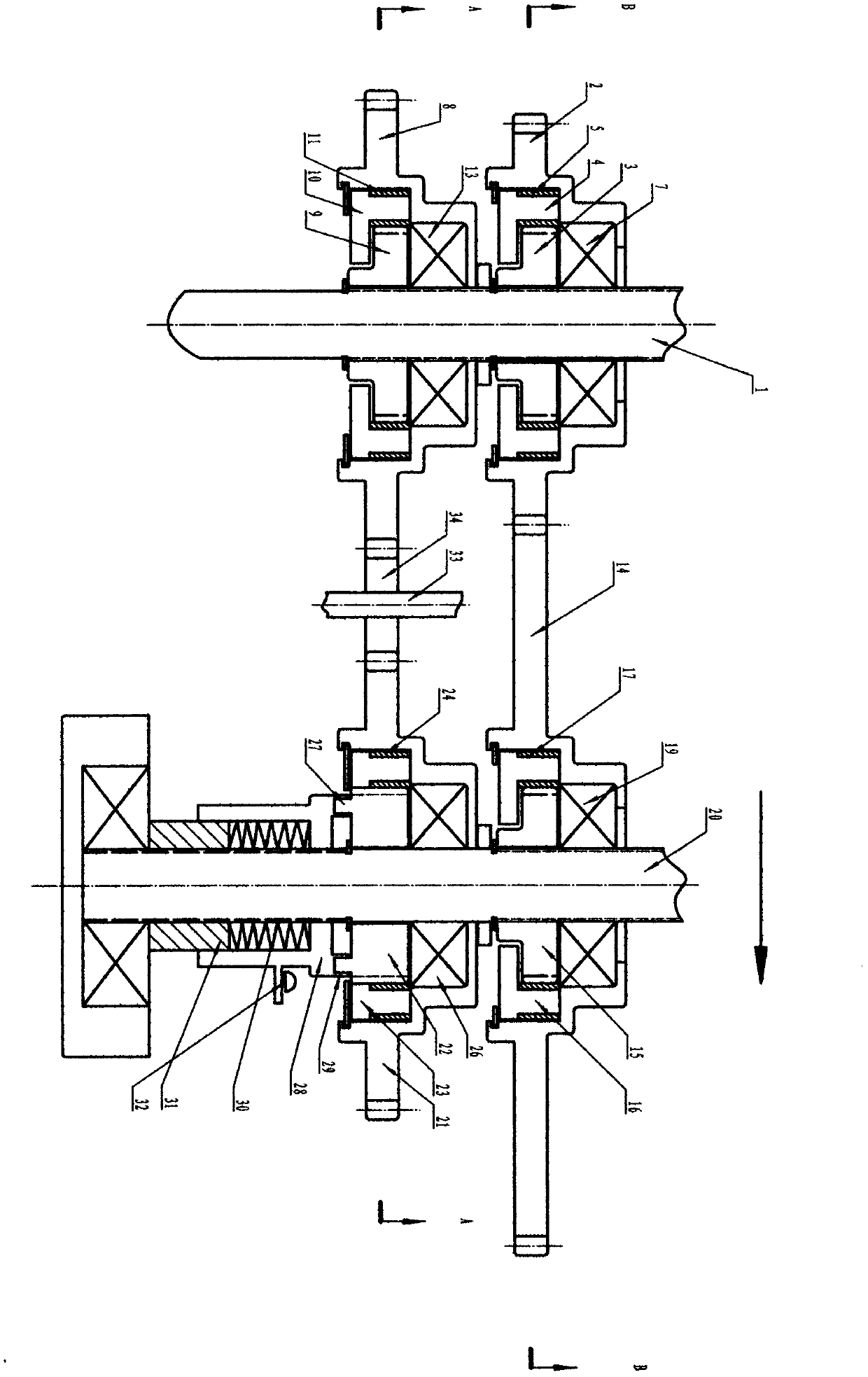

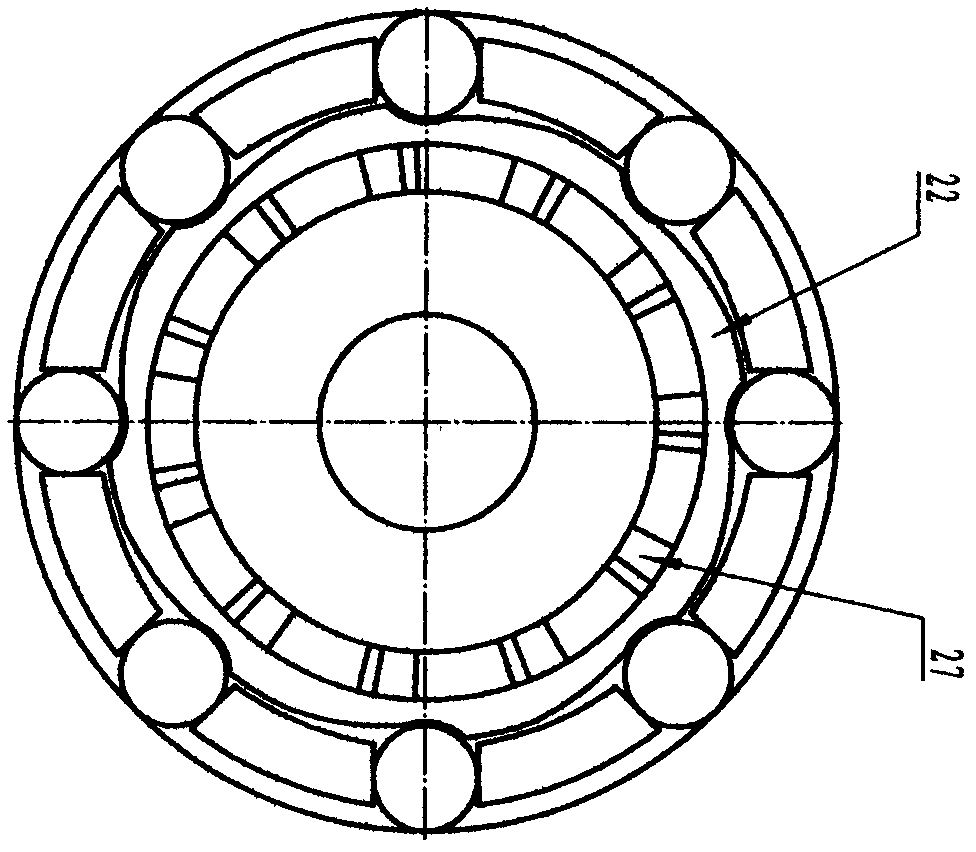

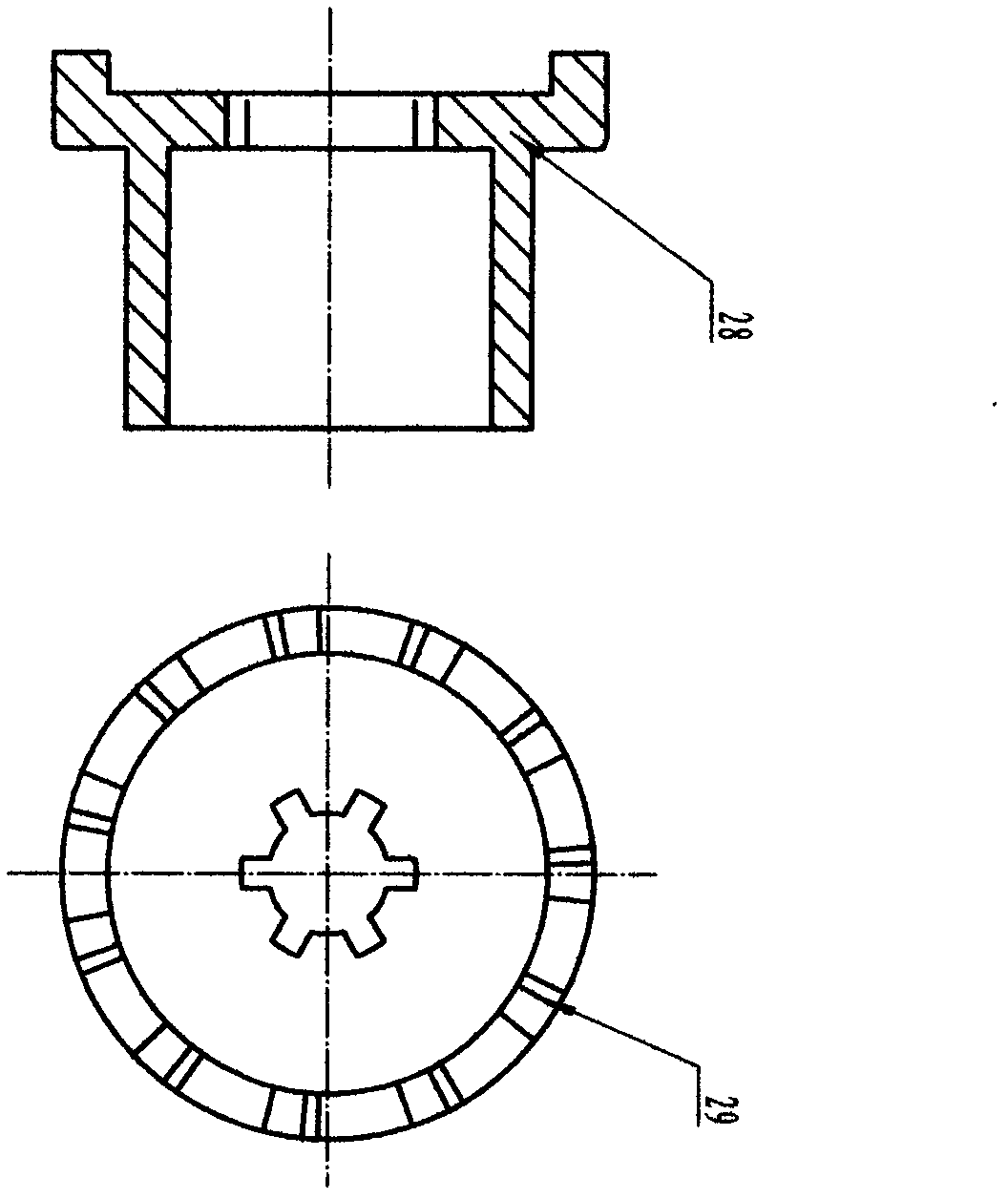

[0020] See figure 1 , figure 2: the second gear driven unidirectional device includes a second gear driven gear 21, the second gear driven gear 21 is installed on the driven shaft 20, and a second gear driven gear 21 is installed at the center of the second gear driven gear 21 The driven cam 22 and the second gear driven bearing 26, the second gear driven cam 22 is looped on the driven shaft 20, and two gears are installed between the second gear driven cam 22 and the inner wall of the second gear driven wheel 21. The gear driven floating sleeve 23 is provided with a group of second gear driven cam curved surfaces 22a on the outer circumference of the second gear driven cam 22, and the second gear driven cam curved surfaces 22a are all smooth curved surfaces with lift characteristics, and Each second gear driven cam curved surface 22a is distributed clockwise (from low to high) on the outer circumference of the second gear driven cam 22, and the second gear driven floating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com