Piezoelectric quartz crystal group for measuring multi-dimensional force, and manufacturing method for piezoelectric quartz crystal group

A piezoelectric quartz and multi-dimensional force technology, which is applied in the direction of measuring the component of force and the measurement of the property force of the piezoelectric device, can solve the problems of being unable to be applied, and achieve the effect of simple structure, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

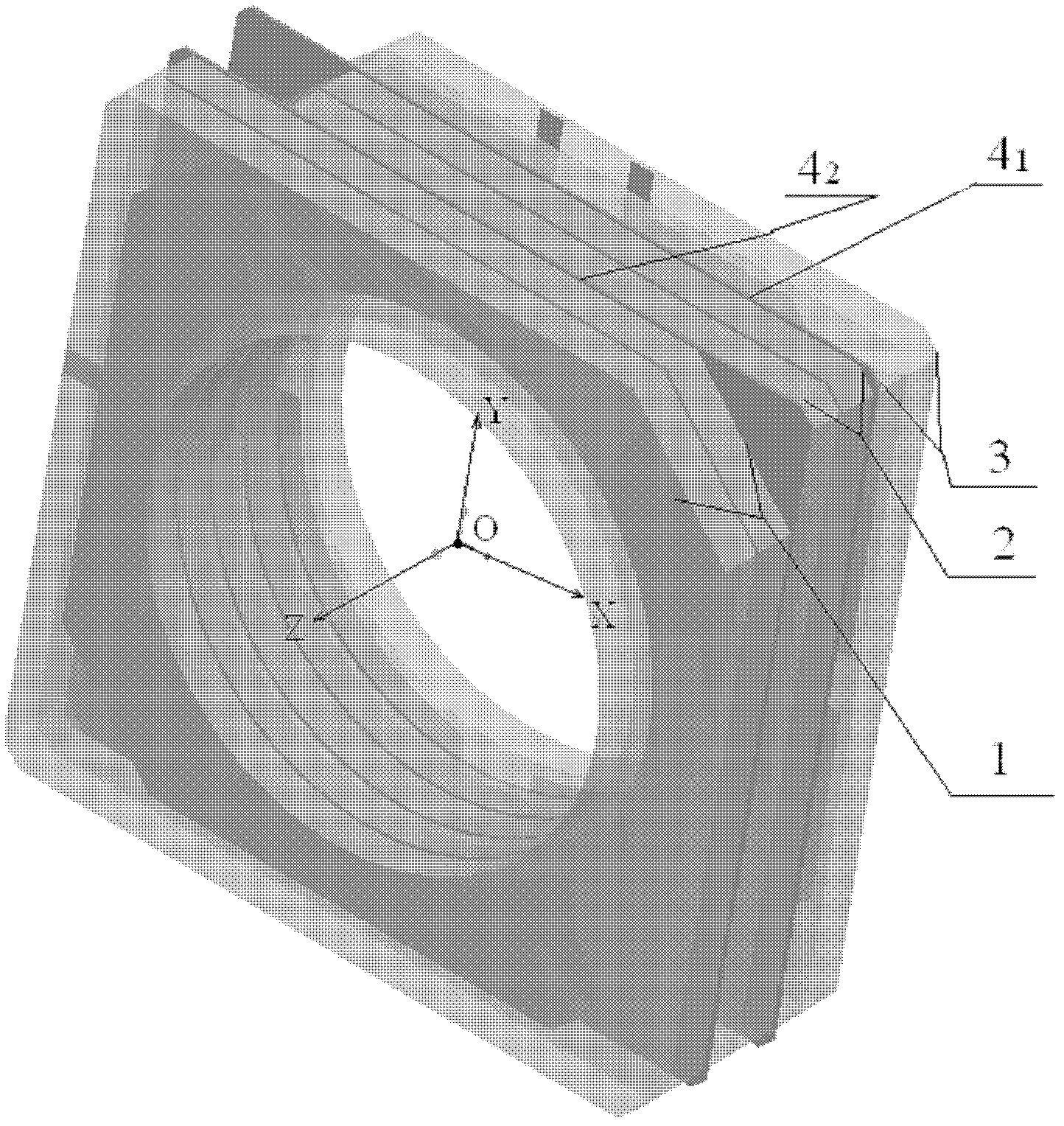

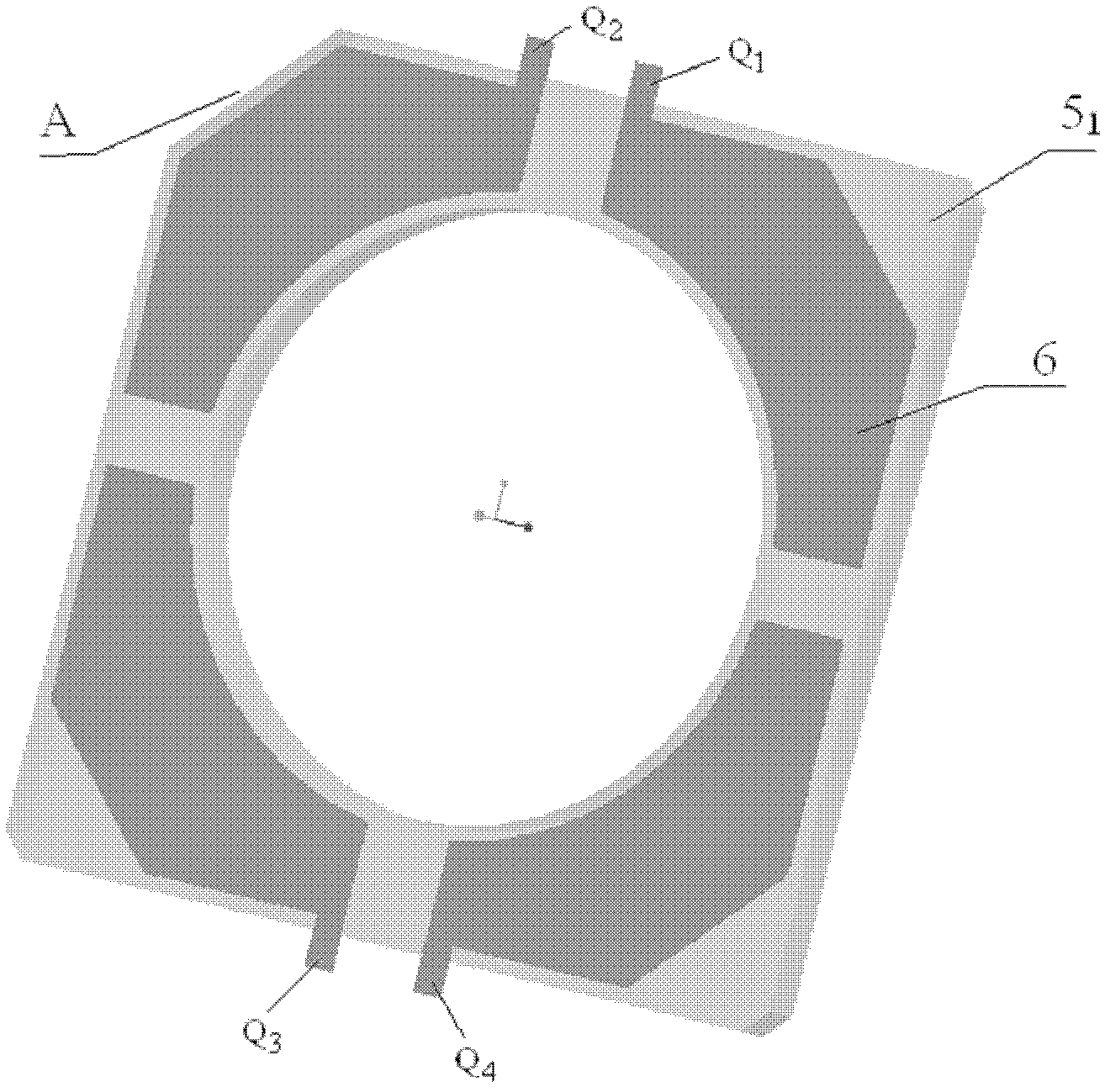

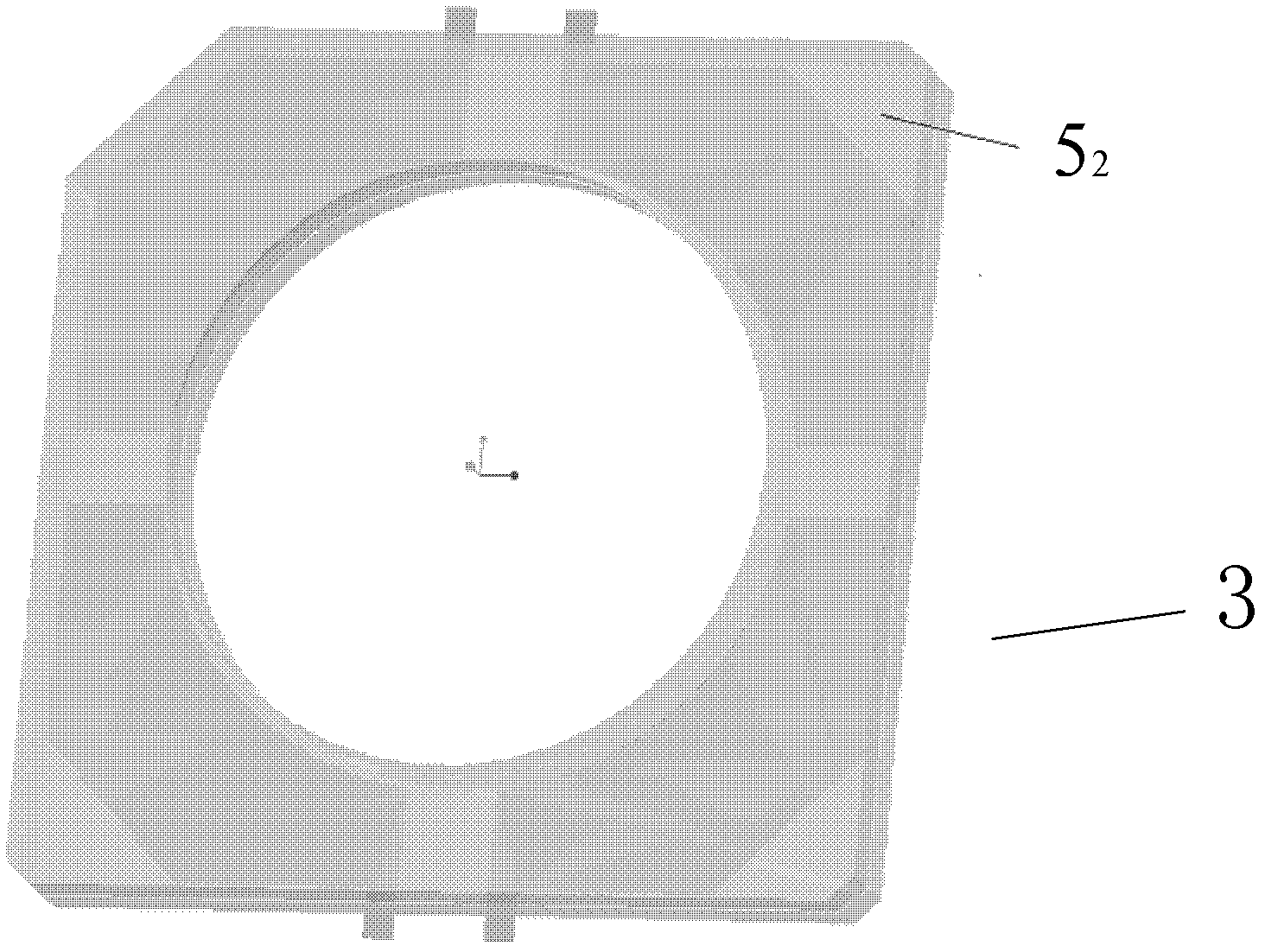

[0020] The implementation of the present invention will be described in detail in conjunction with the technical scheme and accompanying drawings. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the specifications and dimensions of the six quartz wafers are exactly the same, and the equipment is used to mark the direction of the charge sensitivity of the quartz wafer and the surface where the charge output is "-".

[0021] The first quartz wafer 5 cut with one piece of X0 1 As a reference, put the side with the output charge “-” facing up, and apply conductive glue on both sides of four X0 lead-out electrodes 6 of the same shape, and evenly arrange them on the X0-cut first quartz wafer 5 1 On the side where the output charge is "-", ensure that there is no contact between the four electrodes and no contact between the conductive glue. Then the second quartz wafer 5 of another piece of X0 cut 2 The side of the output ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com