Liquid crystal box of flexible liquid crystal display

A technology of flexible liquid crystals and liquid crystal cells, which is applied in instruments, nonlinear optics, optics, etc. It can solve the problems of inability to bend the finished product and the influence of light transmittance, and achieve the effects of improved graphic contrast, light weight, and clear images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

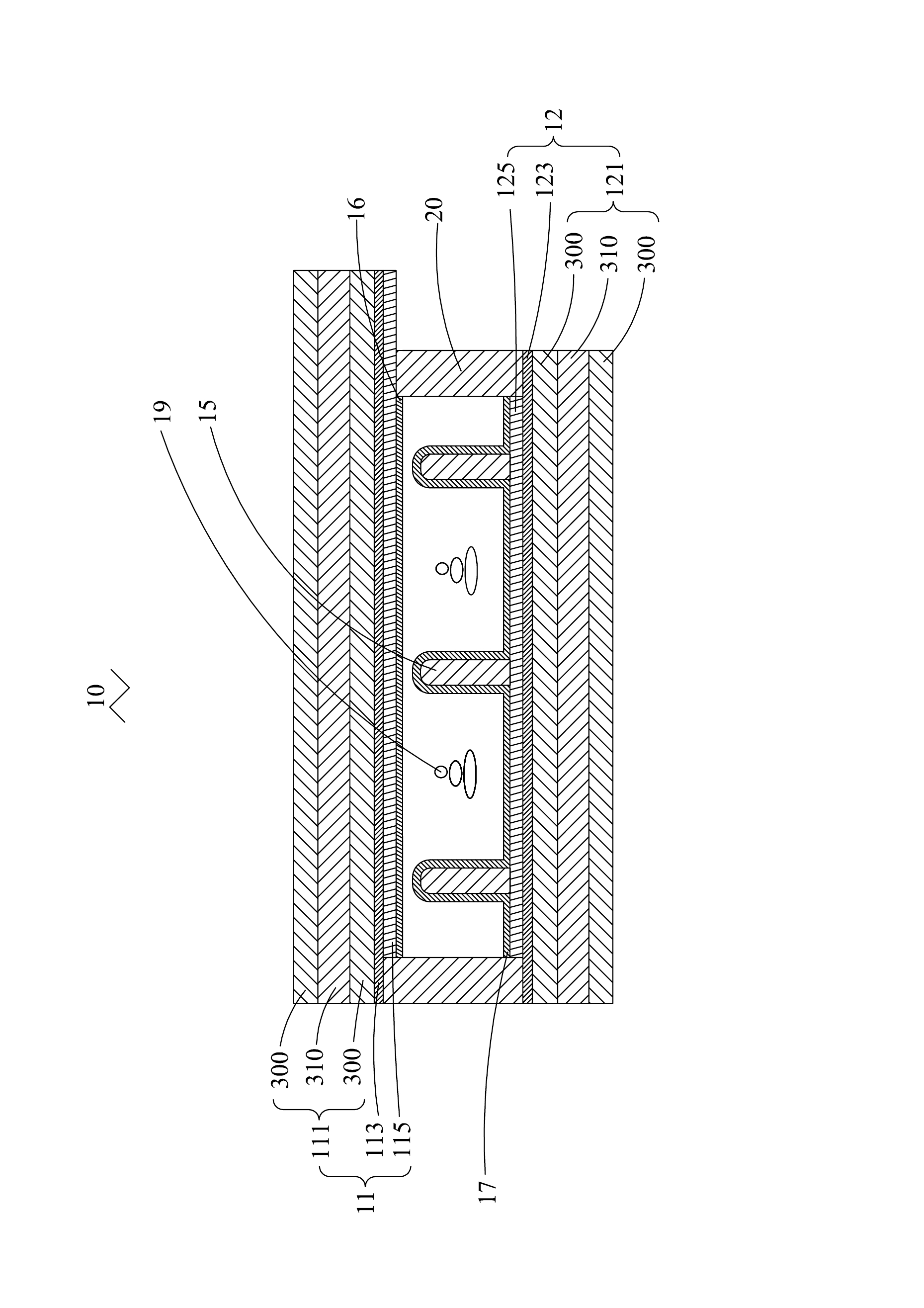

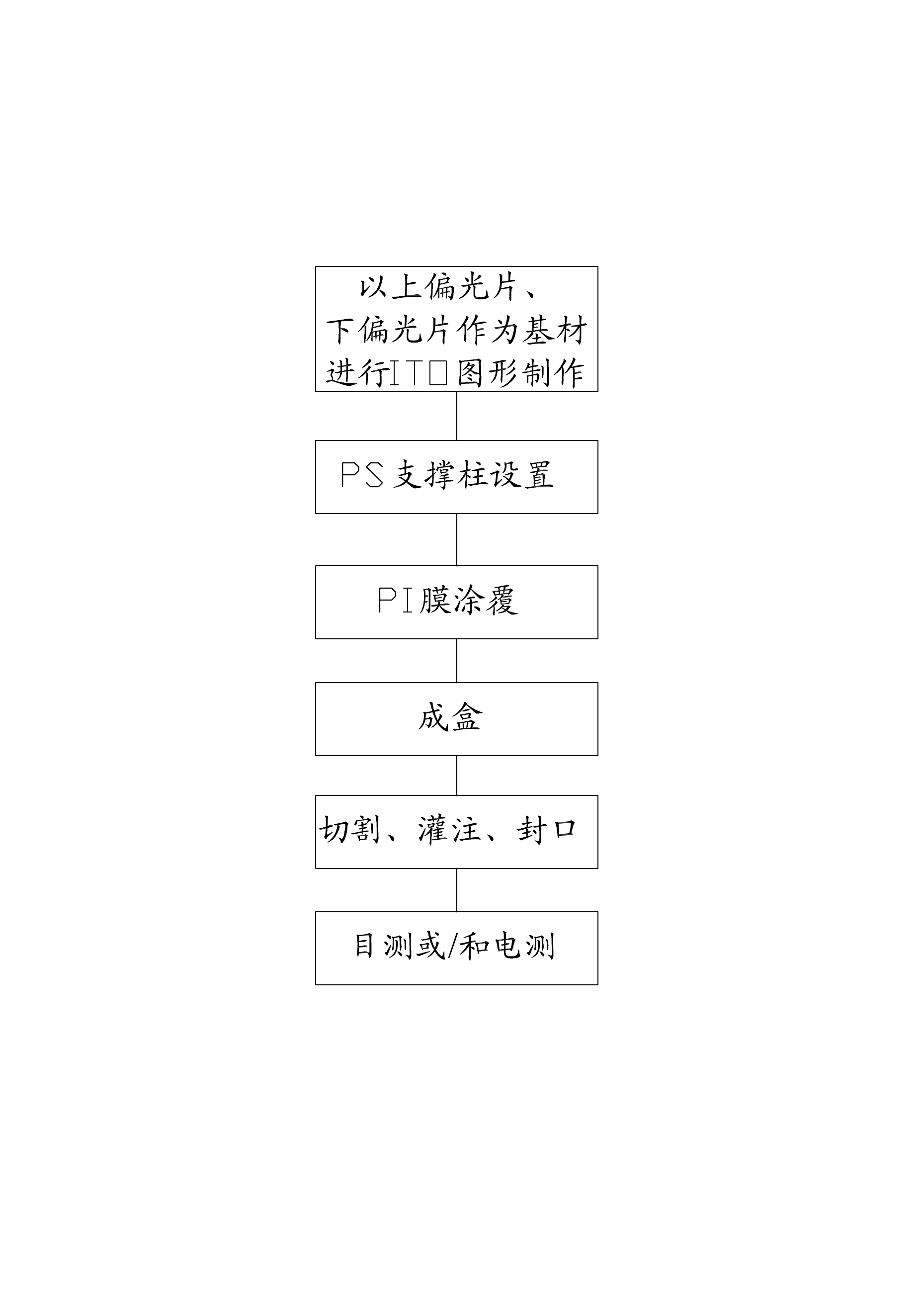

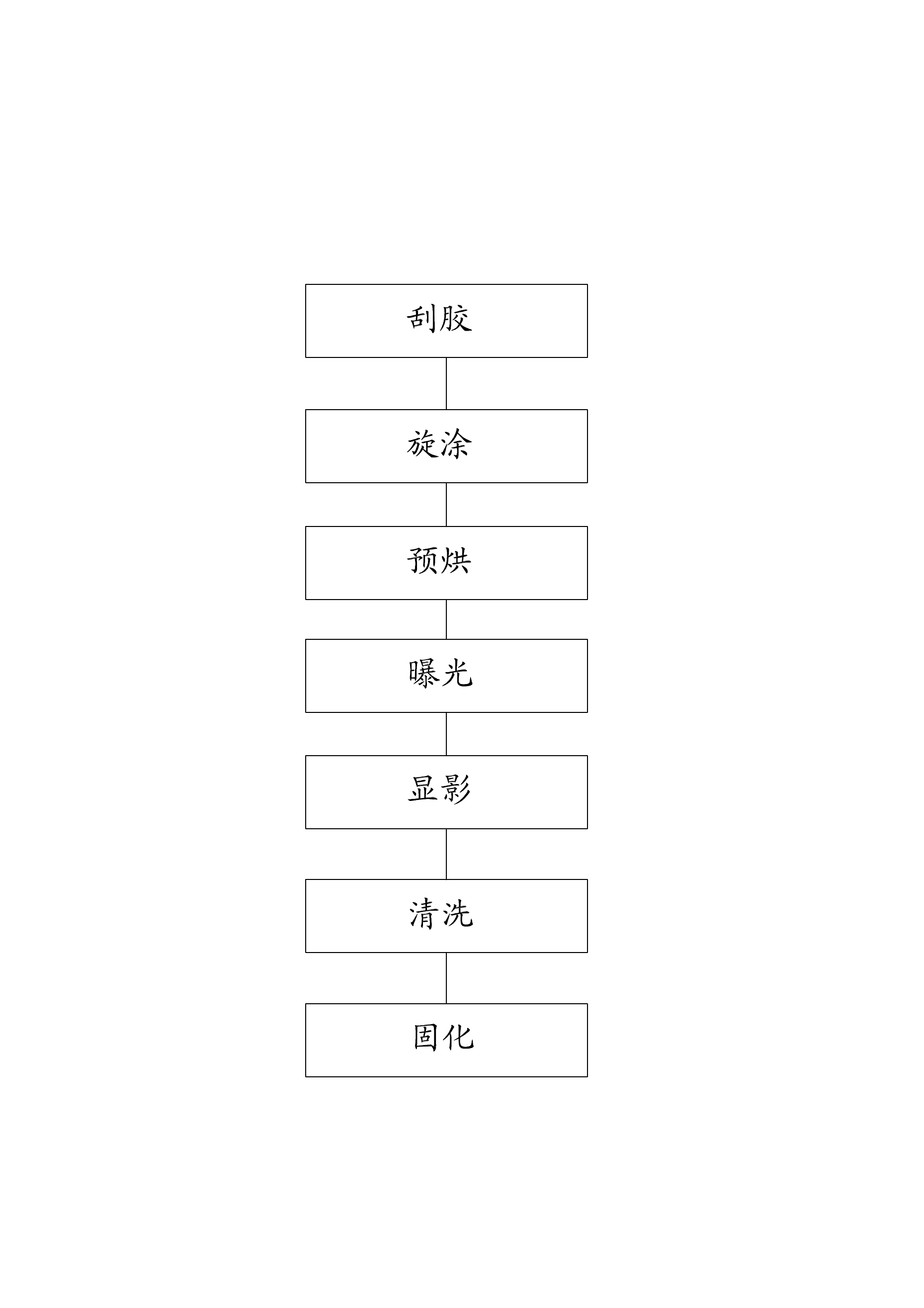

[0022] see Figure 1 to Figure 3 Embodiment 1 of the present invention provides a liquid crystal cell 10 for a flexible liquid crystal display, including an upper flexible conductive substrate 11, a lower flexible conductive substrate 12, a lower PS (photoresist spacer, photosensitive gap material) support column 15, and an upper PI film 16 (polyimide, polyimide), lower PI film 17, liquid crystal 19 and frame glue 20.

[0023] The upper flexible conductive substrate 11 includes an upper polarizer 111 , an upper silicon dioxide layer 113 and an upper ITO film 115 , and the upper polarizer 111 , the upper silicon dioxide layer 113 and the upper ITO film 115 are arranged in sequence. The lower flexible conductive substrate 12 includes a lower polarizer 121 , a lower silicon dioxide layer 123 and a lower ITO film 125 , and the lower polarizer 121 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Curing temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com