Lithography machine chemical interface system and application thereof

An interface system and chemical technology, applied in the field of chemical interface of lithography machine, can solve problems such as prone to errors, and achieve the effect of preventing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

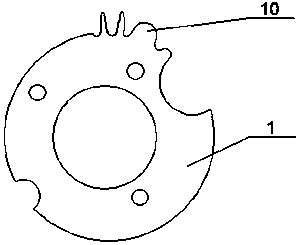

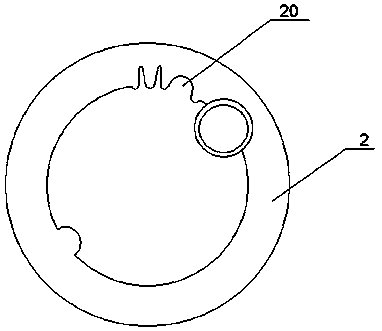

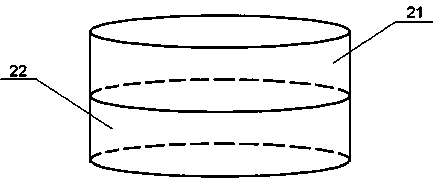

[0022] The invention provides a chemical interface system for a lithography machine and a method for docking a lithography machine with a chemical bottle using the chemical interface system for a lithography machine. It is called the key ring, and the key ring also has the same protrusions as the original design built-in protrusions; and the thickness of the built-in protrusions has been increased. The mouth of the chemical bottle is designed as two rings with the same gap (the upper ring is referred to as A ring, and the lower ring is referred to as B ring), and the A ring can be rotated. When replacing chemicals, remove the key ring and insert it into the A ring. When the protrusion of the key ring matches the gap of the A ring, the key ring can be used to rotate the A ring to make the gap coincide with the B ring gap, which is proof The chemical is correct, remove the key ring, the long tube at the end of the machine can be inserted into a new chemical bottle, and the built...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com