Method for enlarging bonding area of chip

A chip bonding and area technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as poor appearance, grain loss, and increased manufacturing costs, so as to save chemicals and equipment use The effect of reducing the abnormal occurrence of bonded layer shedding, and the operation of the equipment is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

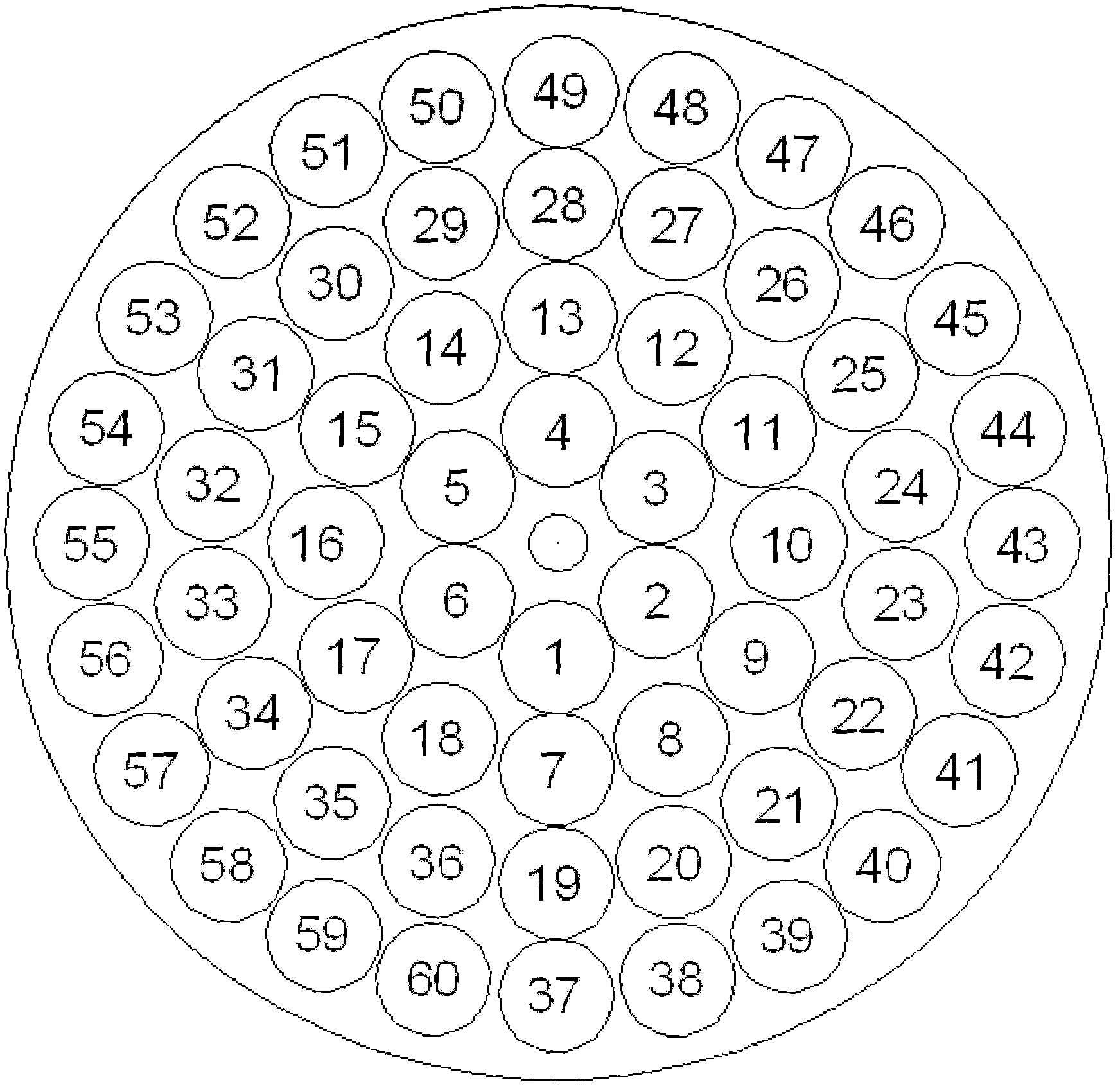

Image

Examples

Embodiment Construction

[0016] The present invention can adopt following implementation method to realize:

[0017] (1) the wafer is cleaned;

[0018] (2) Put the vapor deposition target in the coating machine, then place the wafer in the vertical plating pot, and put the plating pot into the coating machine;

[0019] (3) Vacuuming 4.5×10 -4 Pa, began to evaporate.

[0020] (4) After the evaporation is completed, the wafer is removed from the positive plating pot for bonding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com