InAs/GaSb secondary category superlattice infrared detector

A technology of infrared detector and superlattice, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem that the bandgap width is not large enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

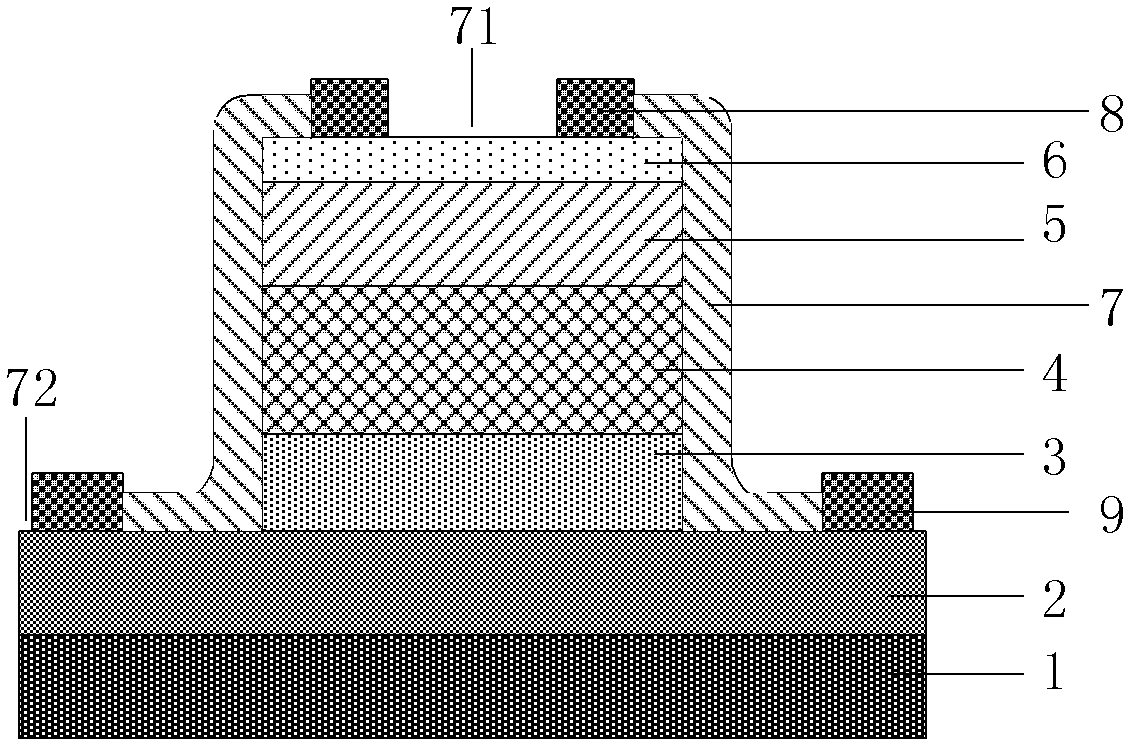

[0025] see figure 1 As shown, the present invention provides a kind of InAs / GaSb class II superlattice infrared detector, comprising:

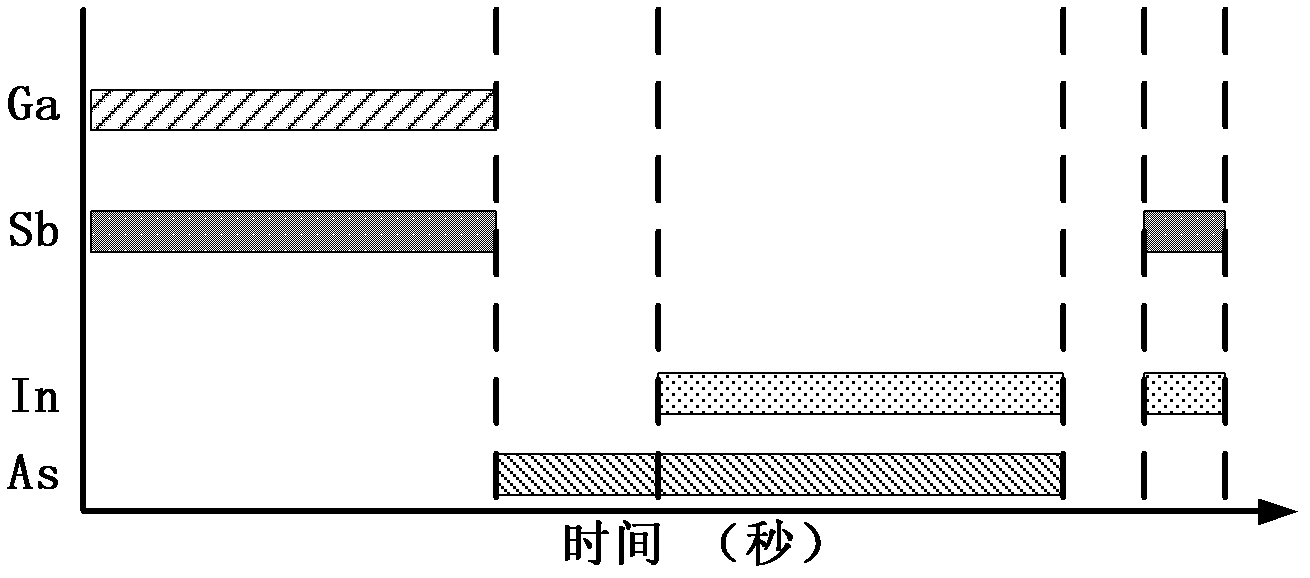

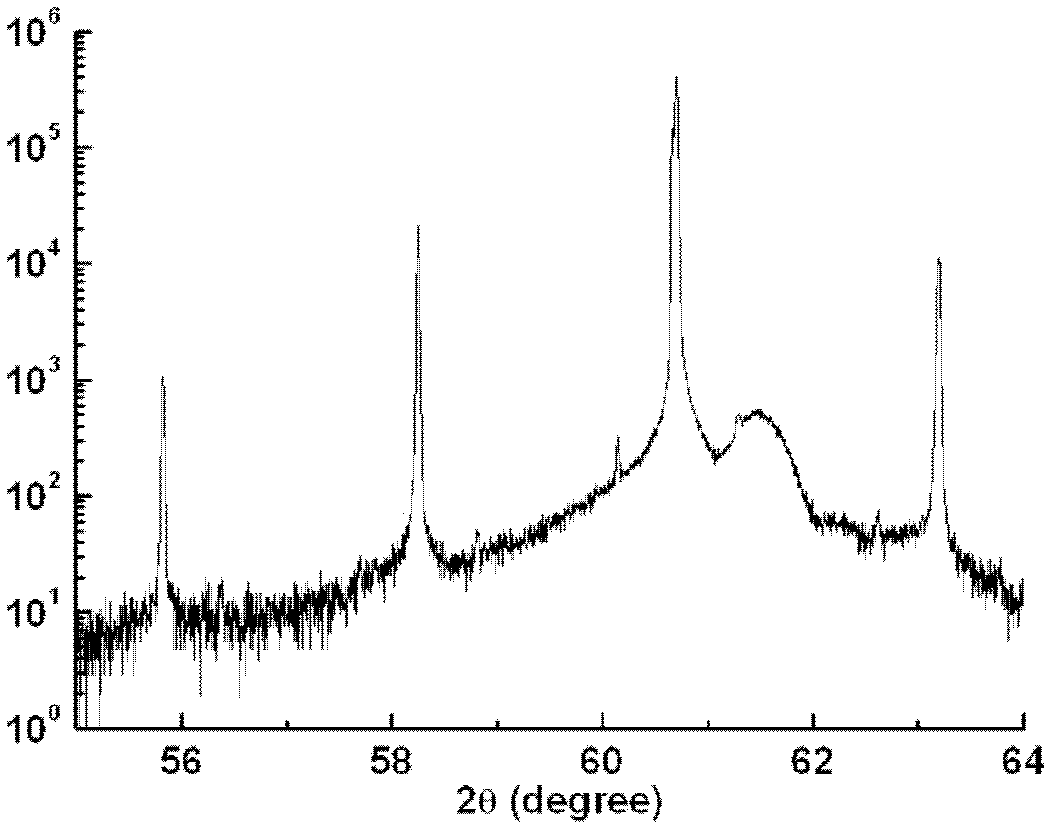

[0026] A substrate 1, the material of the substrate 1 is GaSb; before making the InAs / GaSb type II superlattice infrared detector on the substrate 1, the GaSb substrate 1 is placed in the buffer chamber of the molecular beam epitaxy equipment system The degassing table is degassed, the degassing time is 40 minutes to 2 hours, and the degassing temperature is 180 to 240 ° C; the purpose of degassing is to remove the water vapor on the surface of the GaSb substrate 1 and prevent it from being brought into the growth chamber; then Put the GaSb substrate 1 into the growth chamber of the molecular beam epitaxy equipment system, place it in the growth position, deoxidize at 525°C, raise the temperature of the GaSb substrate 1 to 545°C and protect it under the Sb atmosphere for 5 to 10 minutes. The purpose is to remove oxides on the surface of the G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com