Interdigitated back contact solar battery structure with passivation contact structure and preparation method of solar battery structure

A contact structure and solar cell technology, applied in the field of solar cells, can solve problems such as coexistence of positive and negative electrodes, difficulty in welding battery components, and impact on battery reliability, and achieve low cost, reduced space complexity, and reduced welding difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A method for preparing an interdigitated back-contact solar cell with a passivation contact structure, comprising the steps of:

[0057] 1) Texturing the surface of the front side of the n-type silicon substrate 1;

[0058] 2) Form a backside passivation tunneling layer 11 on the backside of the n-type silicon substrate 1; then pattern the second doped region 4 and the first doped region 3 on the backside of the n-type silicon substrate 1, so that the first doped region 3 Alternating with the second doped region 4 in the form of interdigitated fingers; preparing an n-type surface doped layer or a p-type positive surface doped layer on the front side of the silicon substrate 1;

[0059] 3) Prepare a rear passivation film 5 on the back of the n-type silicon substrate 1, and prepare a front passivation and anti-reflection film 2 on the front of the n-type silicon substrate 1;

[0060] 4) Prepare battery electrodes on the back passivation film 5 .

[0061] Step 2 also inc...

Embodiment 1

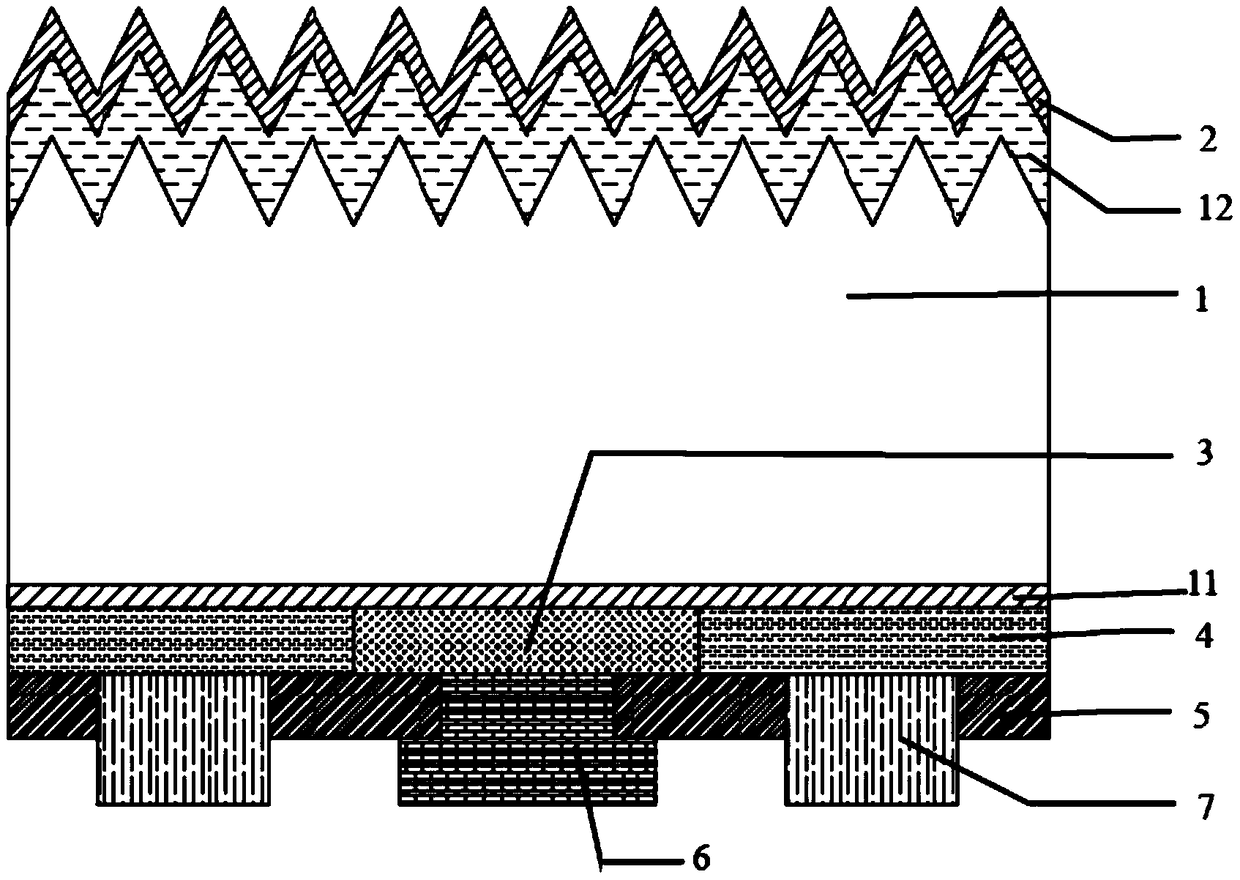

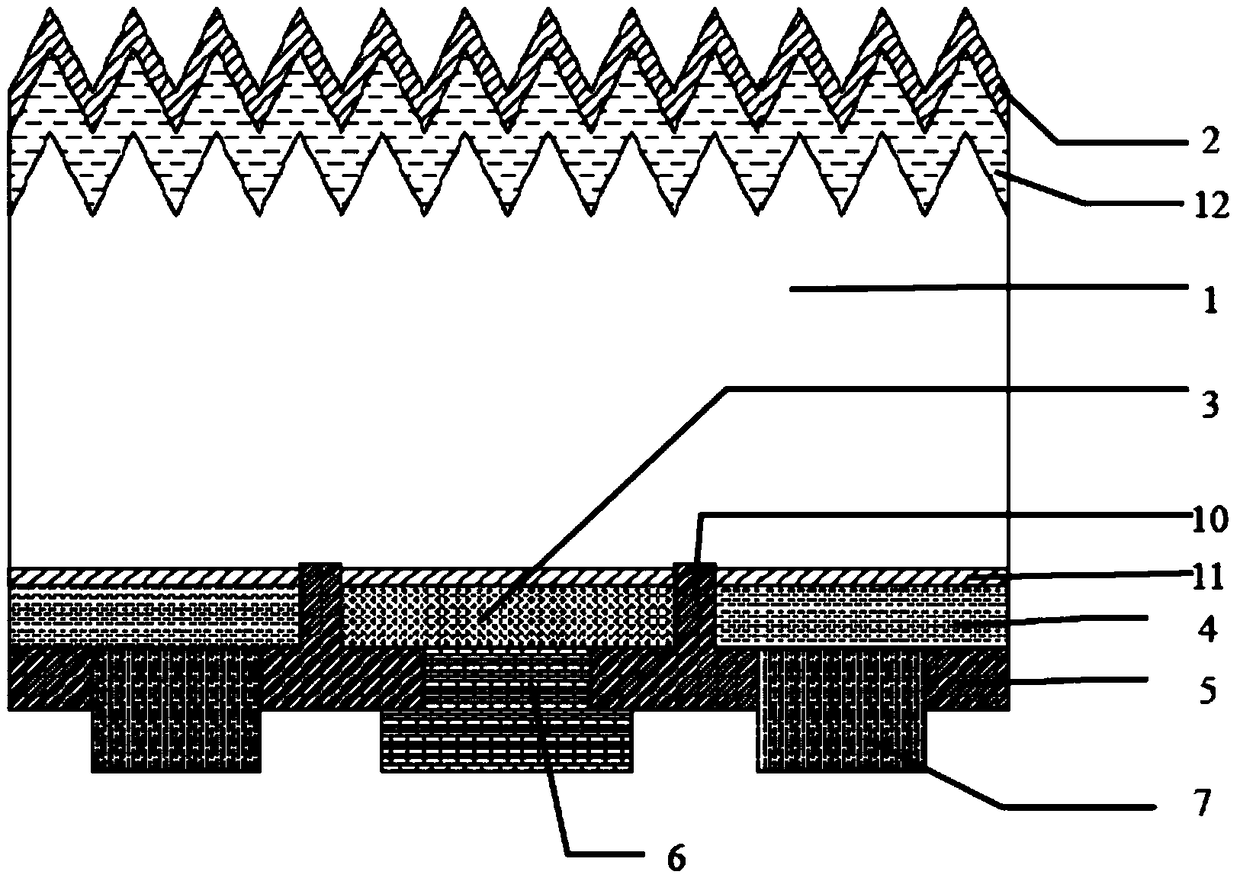

[0066] like figure 1 and Figure 7 As shown, a structure of interdigitated back-contact solar cells, this embodiment uses n-type silicon wafers as the substrate, this cell includes from top to bottom: front passivation and anti-reflection film, n-type front surface doping Layer 12, n-type silicon substrate 1, back passivation tunneling layer 11, back doped film layers 3 and 4, back passivation film and battery electrodes; wherein the back doped film layer has the first doped region 3 on the back and the back doped film layer The first doped region 3 on the back side of the second doped region 4 is composed of one or more of polysilicon, amorphous silicon, and microcrystalline silicon, and is doped with group V elements; the second doped region 4 on the back is made of polysilicon, amorphous silicon Composed of one or more of crystalline silicon and microcrystalline silicon, and doped with Group III elements;

[0067] The first doped region 3 on the back side and the second d...

Embodiment 2

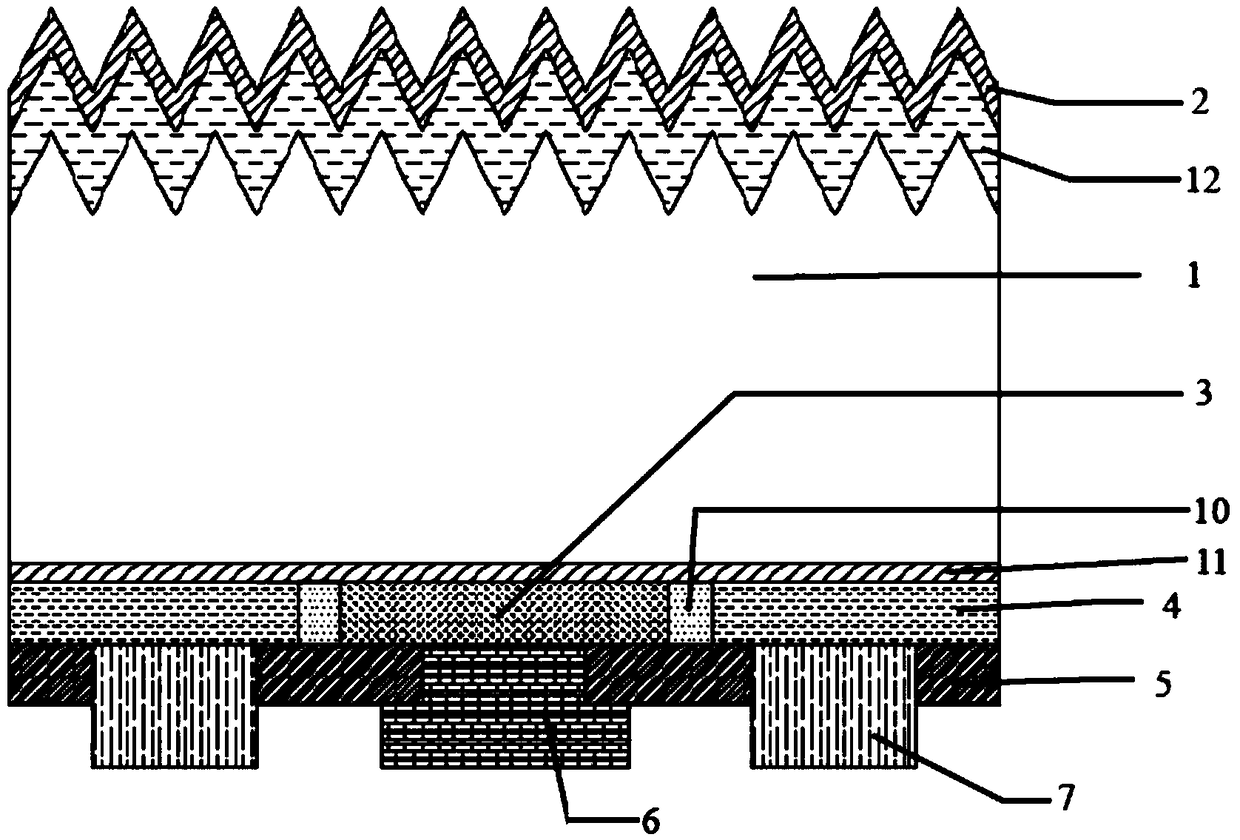

[0080] like figure 2 and Figure 7 , Figure 8 As shown, but the front surface doped layer 12 uses p-type as the front surface doped layer 12. In this case, a floating pn junction is formed on the front surface, which can also enhance the passivation of the front surface. Other structures are similar to those of Embodiment 1.

[0081] The structure of this interdigitated back-contact solar cell, this cell includes from top to bottom: front passivation and anti-reflection film, p-type front surface doped layer 12, n-type silicon substrate 1, back passivation tunneling Layer 11, the back first doped region 3 and the back second doped region 4, the back passivation film and the battery electrode; the back first doped region 3 is made of one or more of polysilicon, amorphous silicon, and microcrystalline silicon The second doped region 4 on the back is composed of one or more of polycrystalline silicon, amorphous silicon, and microcrystalline silicon, and is doped with group I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com