Preparation method for battery diaphragm

A technology of battery diaphragm and diaphragm, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of lithium-ion battery diaphragm defective occurrence rate, production requirements and high cost, so as to save cost, reduce requirements and improve pull The effect of elongation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

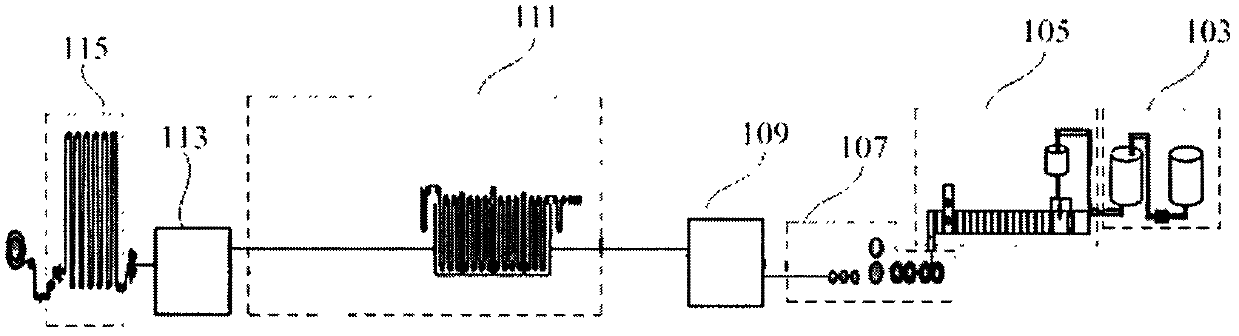

[0036] Embodiment 1, a battery diaphragm in this embodiment, especially a lithium-ion battery diaphragm preparation method, the steps are as follows:

[0037] 1. Add ultra-high molecular weight polyethylene, antioxidant and mineral oil into the mixer in a certain proportion to fully stir the raw materials. Among them, the mass ratio of mineral oil to antioxidant is 1000-2000:1, mineral oil and The mass ratio of ultra-high molecular weight polyethylene is 2-10:1.

[0038] The ultrahigh molecular weight polyethylene in this example has a molecular weight of 1 million or more.

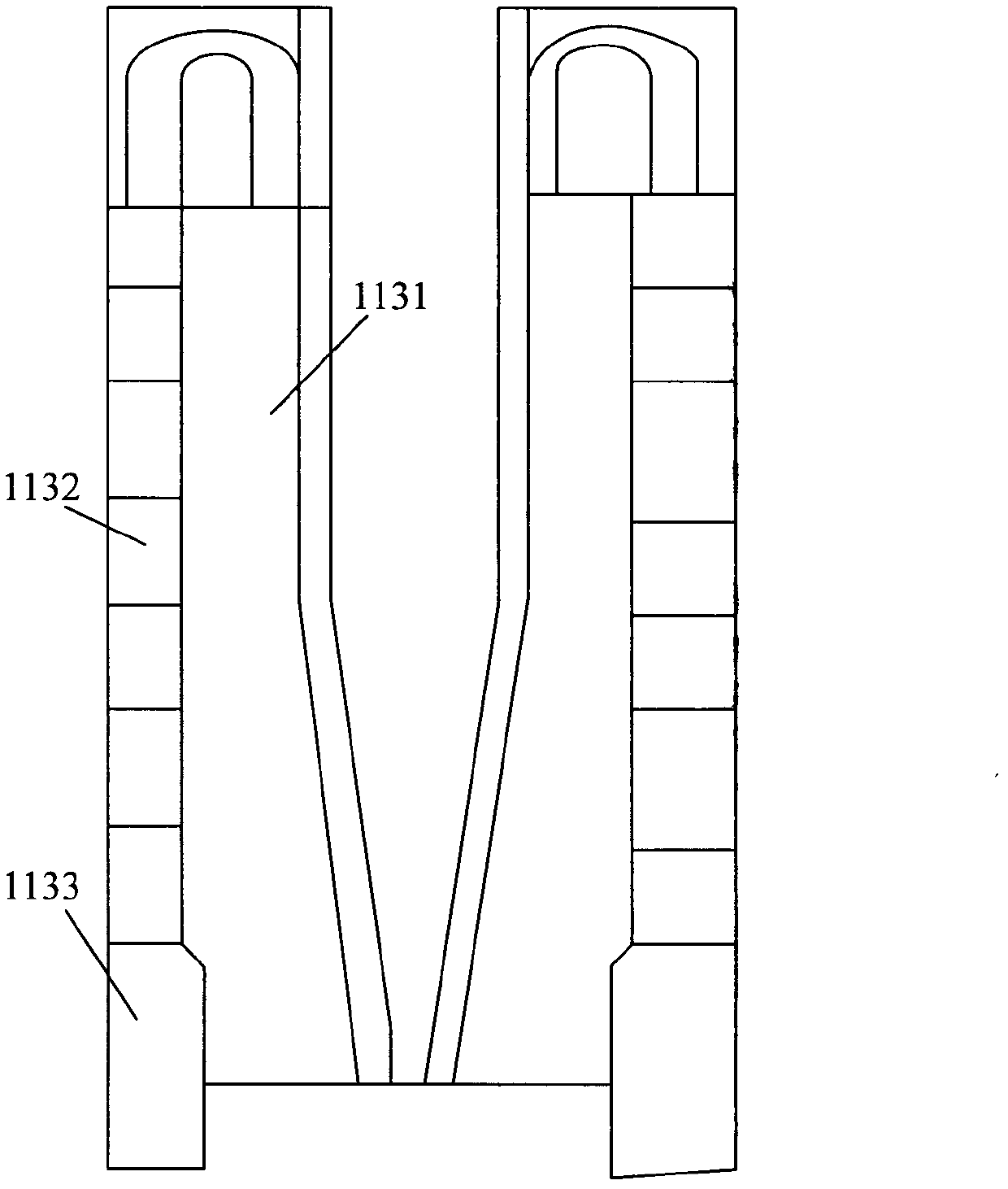

[0039] 2. Put the mixture stirred in step 1 into a twin-screw extruder to heat and extrude continuously to form a substrate.

[0040] Here, the diameter of the screw of the twin-screw extruder is 10-150 millimeters, and its extrusion capacity is greater than 200 kilograms per hour.

[0041] 3. The substrate extruded from the twin-screw extruder is cooled and formed by a set of cooling rollers;

[0042]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com