Method for plasma-cutting a workpiece by means of a plasma-cutting system and pulsating current

A technology of cutting equipment and cutting current, which is applied to plasma welding equipment, welding equipment, metal processing equipment, etc., and can solve problems such as replacement and electrode damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

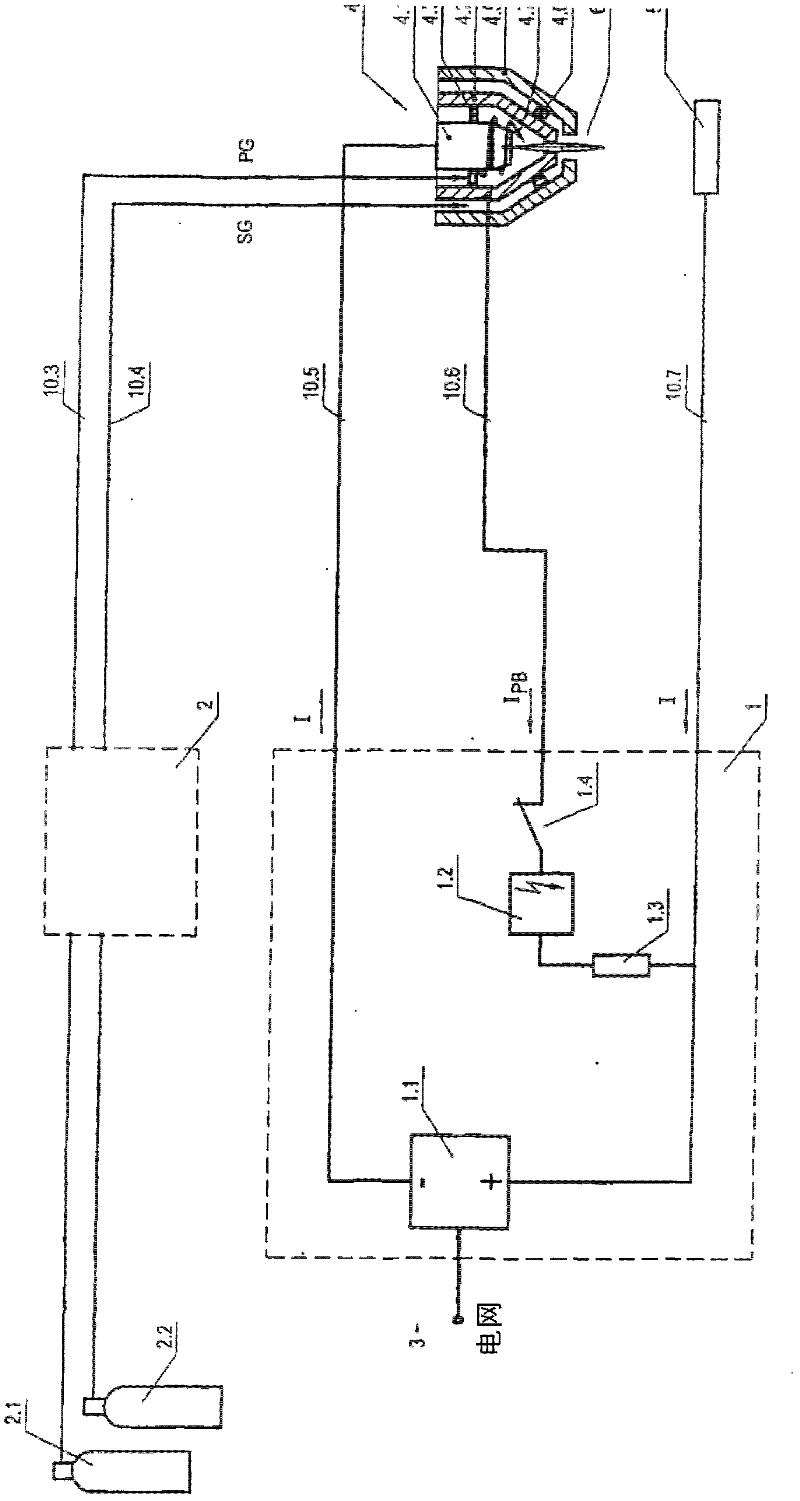

[0057] figure 1 A schematic diagram of a plasma cutting system according to the prior art is shown, which has a plasma current source 1 whose components are a current source 1.1, an igniter 1.2, a resistor 1.3 and contacts 1.4. The negative pole of the current source utilizes lead 10.5 to be connected with the electrode 4.1 of plasma burner 4, and positive pole is connected with workpiece 5 through lead 10.7 and is connected with the nozzle 4.2 of plasma burner 4 through lead 10.6 by resistance 1.3, igniter 1.2 and contact 1.4. The plasma current source is usually powered by a three-phase AC grid, such as 400V / 50Hz. The gas supply of the plasma burner is realized here via the gas console 2, in which there may be valves, such as magnetic valves and / or regulating valves (not shown), for switching the gas, in particular the plasma gas PG, and the secondary Gas SG. The gas supply takes place in this example via a gas cylinder 2.1 for the plasma gas and a gas cylinder 2.2 for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com