Nitrogen gas injection apparatus

A technology of nitrogen and injection holes, applied in mechanical equipment, electrical components, flange connections, etc., can solve problems such as complex processes, difficulties, and rising production costs, and achieve the effect of facilitating manufacturing, facilitating production, and promoting flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

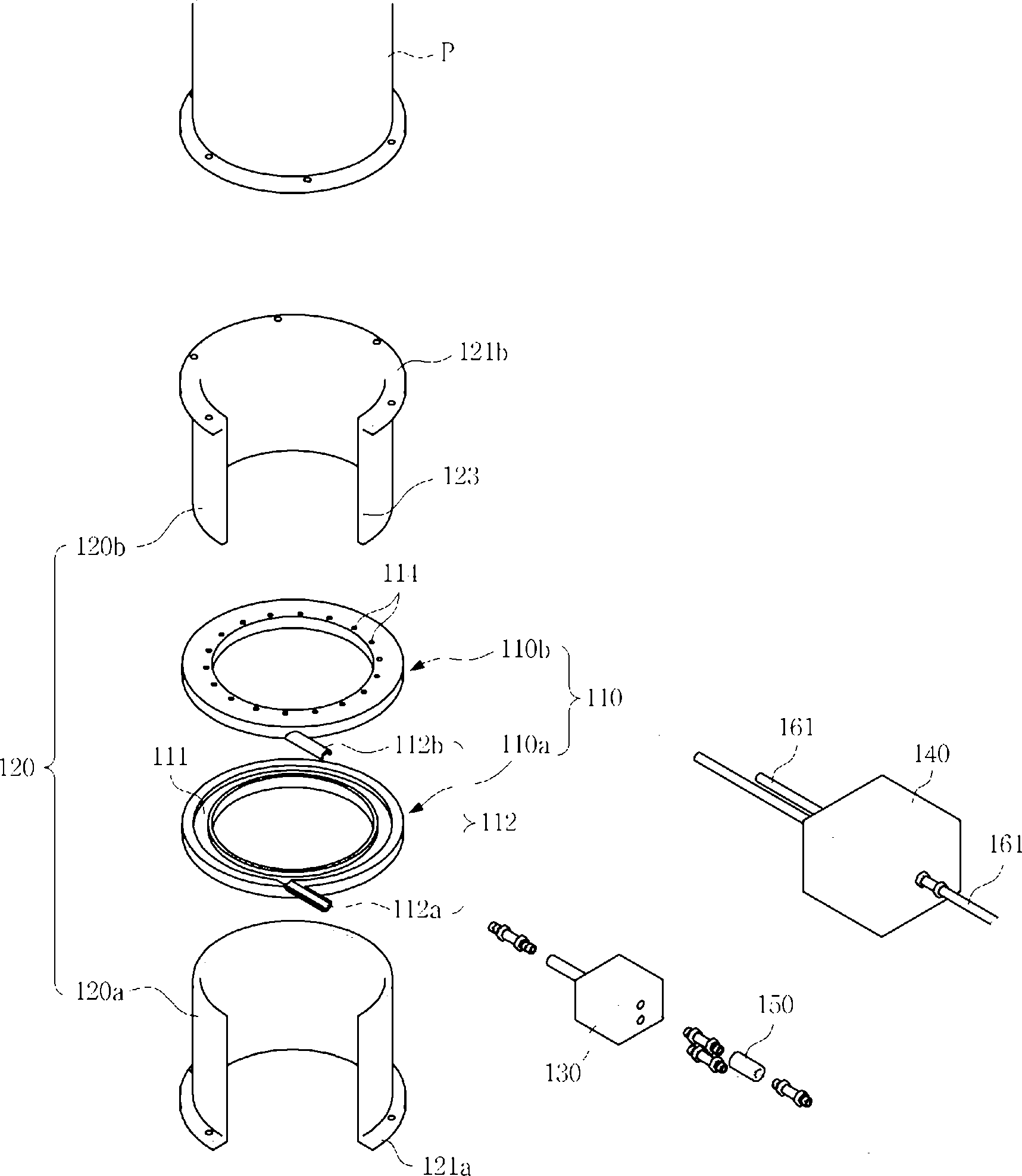

[0038] Preferred exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

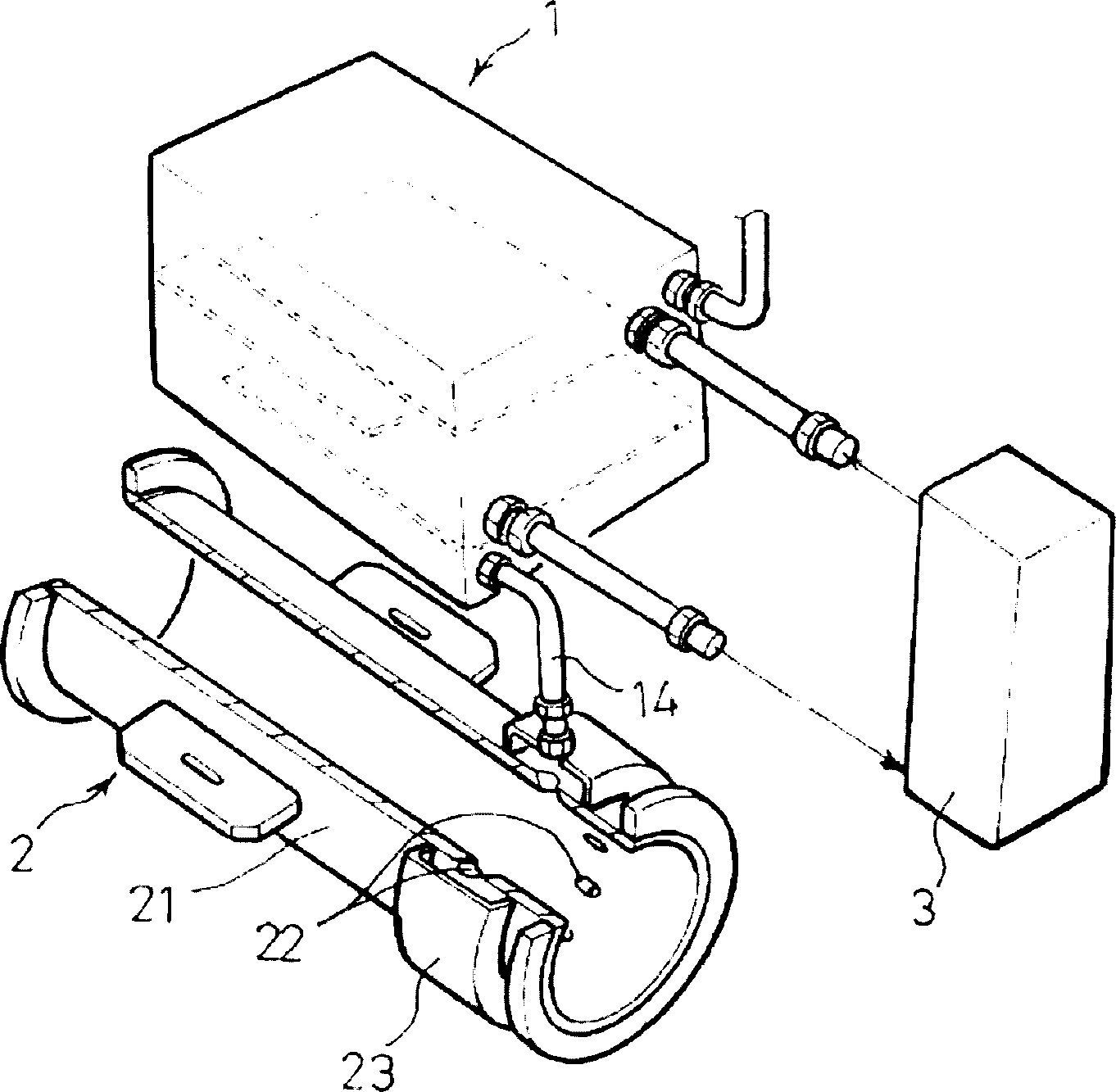

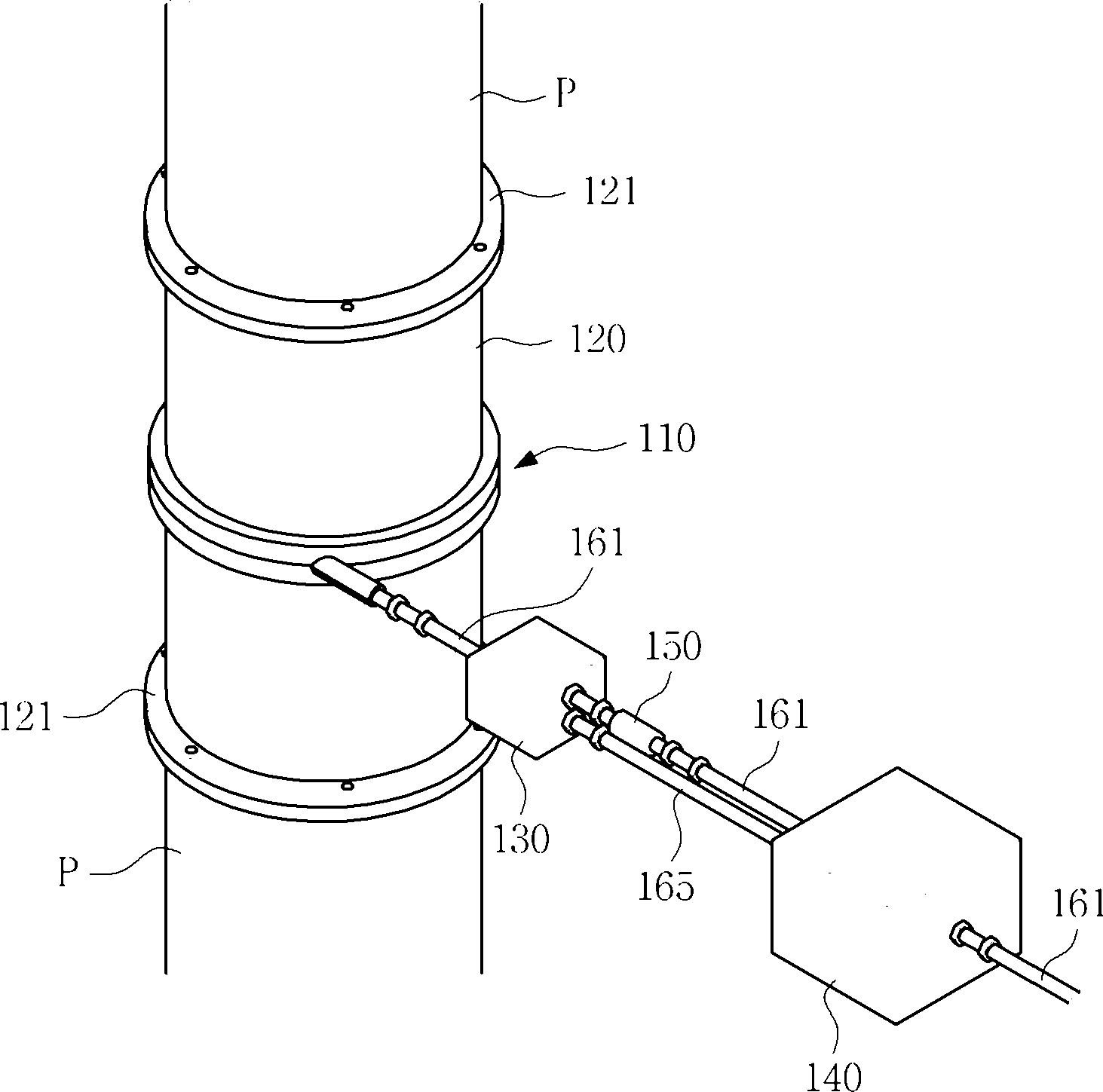

[0039] figure 2 Shown is an installation state diagram of a nitrogen injection device according to the present invention.

[0040] As shown, the nitrogen injection device of the present invention can be selectively installed on any pipe P at the outlet side of the process chamber, at the inlet or outlet side of a vacuum pump, or at the inlet or outlet side of a scrubber. The nitrogen injection device of the present invention can be easily installed in each pipe P, and the direction of nitrogen injection is controlled to be the same as the flow direction of the by-product gas, thereby facilitating installation in the exhaust pipe of the vacuum pump, the exhaust pipe of the scrubber, and the process chamber The vacuum tube on the outlet side of the chamber will not affect the vacuum level during the process.

[0041] As mentioned above, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com