Three-color automatic diamond stacking machine

An automatic, drilling rig technology, applied in clothing, applications, jewelry, etc., can solve the problems of cumbersome manual operation, low work efficiency, large workload, etc., to reduce labor intensity, save manpower, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

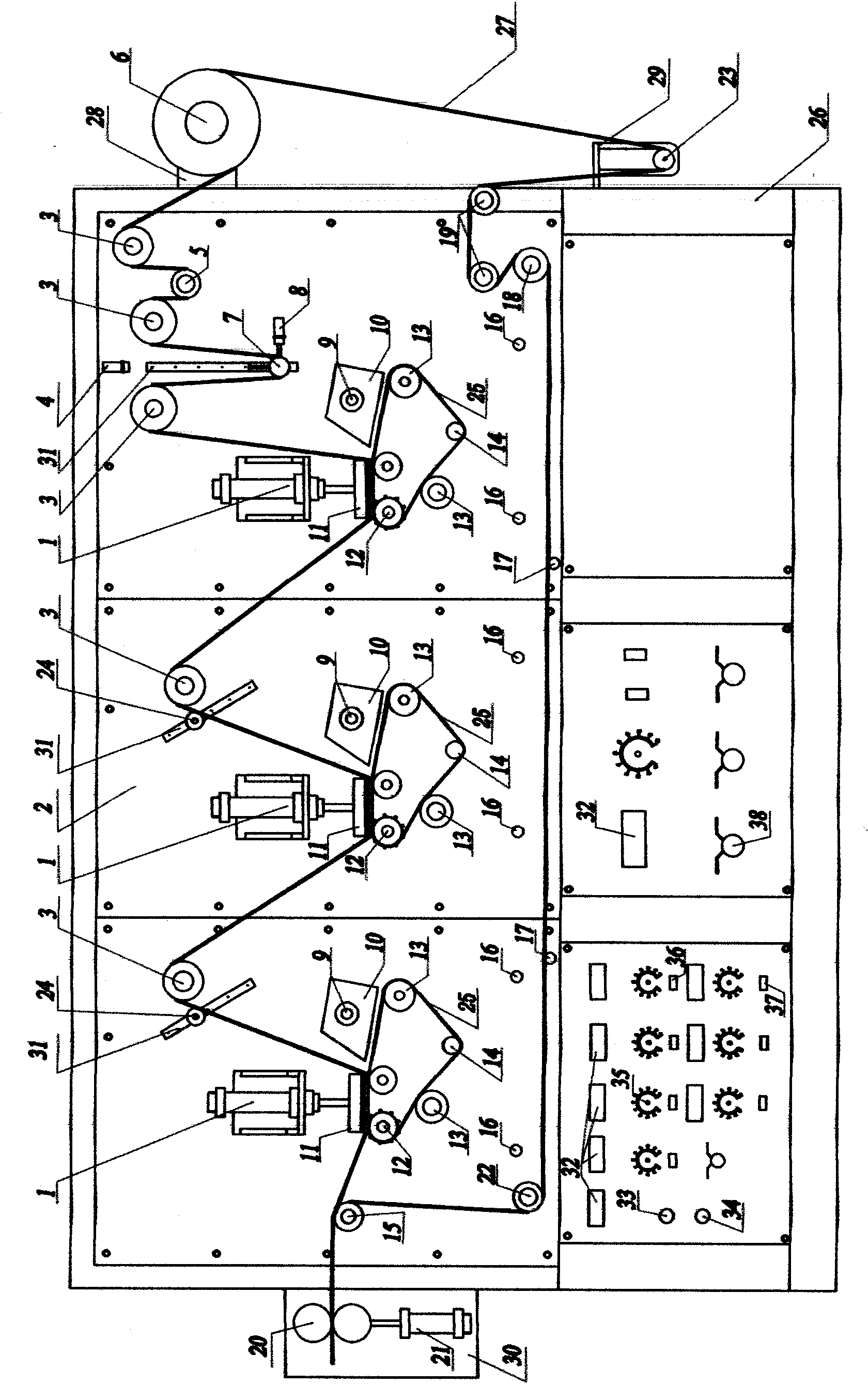

[0016] The three-color automatic coding drilling machine of the present invention is realized in this way, and is described in detail below in conjunction with the accompanying drawings. See figure 1 , the three-color automatic code drilling machine of the present invention is composed of: platen cylinder 1, fixed panel 2, support rubber roller 3, emergency stop automatic switch 4, paper feeding drive shaft 5, paper supporting wheel 6, paper feeding force adjustment shaft 7, tension Automatic adjustment switch 8, swing shaft 9, drill box 10, pressure plate 11, drill drive shaft 12, drill support roller 13, gravity adjustment shaft 14, paper output support roller 15, tray support shaft 16, lower paper support shaft 17, Drive shaft for lower paper 18, paper output support shaft 19, drill paper traction shaft 20, traction cylinder 21, lower paper idler roller 22, gravity roller 23, tension adjustment shaft 24, drill plate 25, frame 26, drill paper 27, support paper Wheel bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com