Organic waste gas concentrating, absorbing and catalyzing combustion device

A technology for adsorption, catalysis, and organic waste gas, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of time-consuming treatment and high cost, and achieve the effect of wide application, simple structure and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

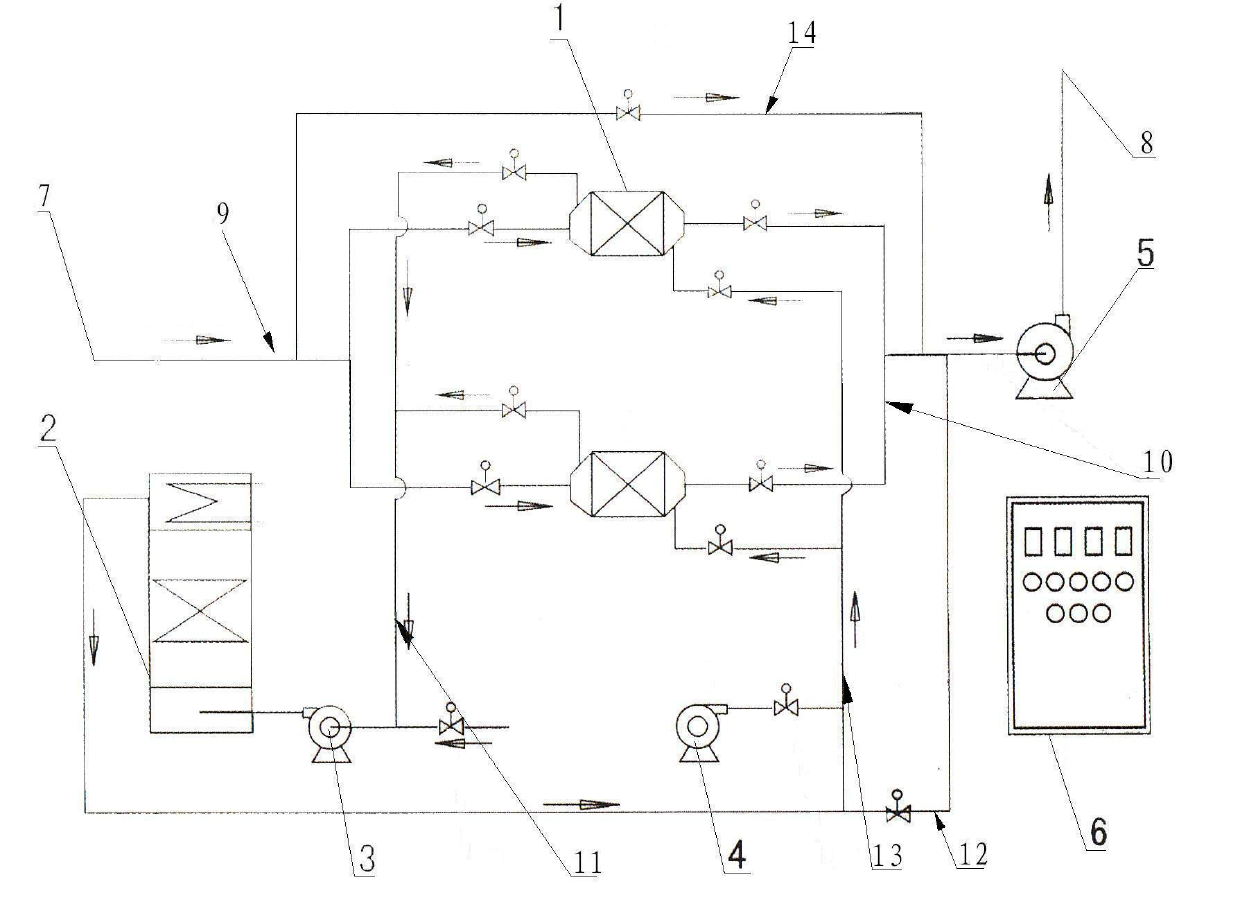

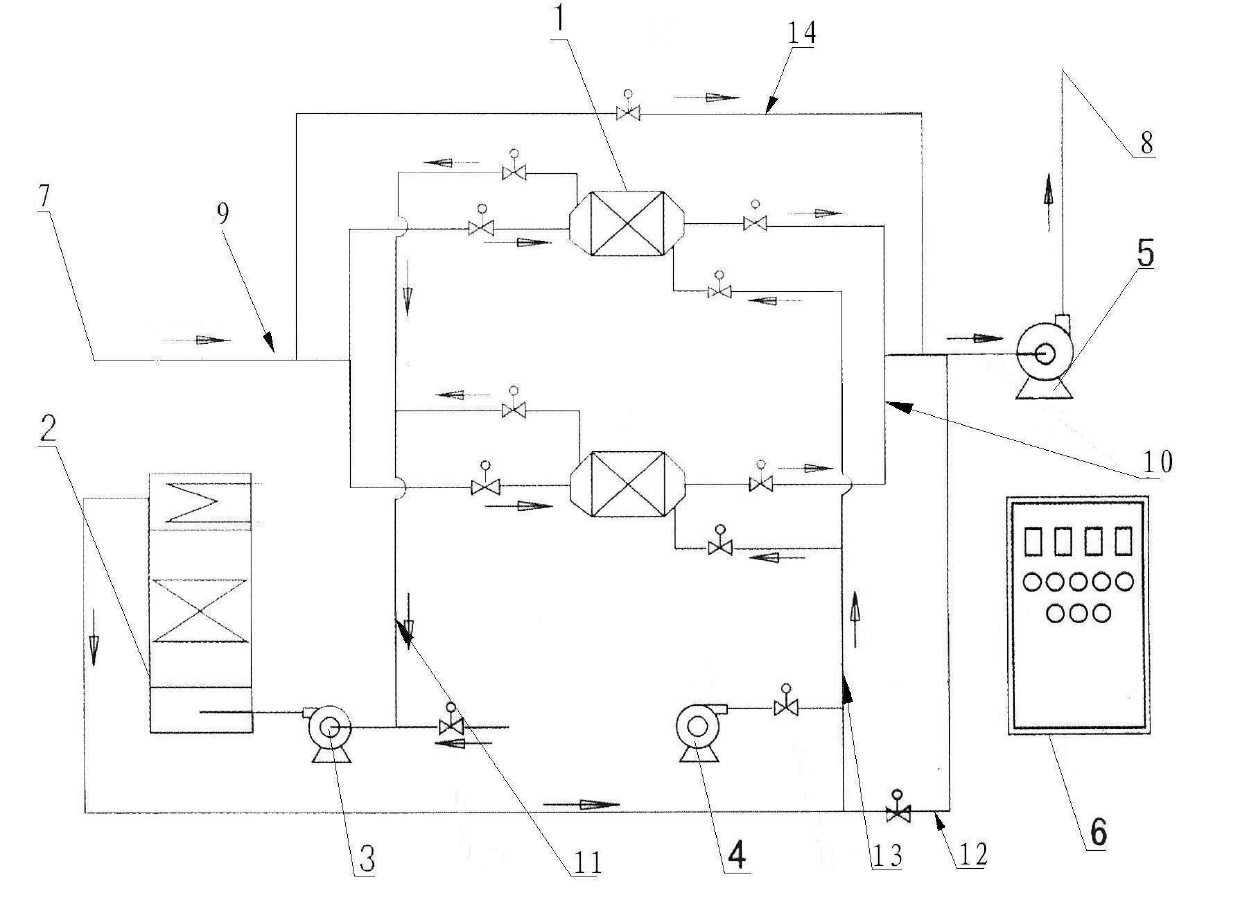

[0017] like figure 1 The shown organic waste gas concentration adsorption catalytic combustion device includes a waste gas inlet 7 for inputting waste gas, a clean gas outlet 8 for outputting clean gas, at least one adsorption tank 1 filled with an activated carbon adsorption layer, and a catalytic combustion device 2 And electric control box 5. There are two adsorption tanks 1, and the two adsorption tanks 1 are arranged in parallel. The adsorption tank 1 is communicated with the exhaust gas inlet 7 through the first pipeline 9, the adsorption tank 1 is communicated with the clean gas outlet 8 through the second pipeline 10, and the adsorption tank 1 is communicated with the catalytic combustion device 2 through the third pipeline 11, The catalytic combustion device 2 communicates with the clean gas outlet 8 through a fourth pipeline 12 . The adsorption t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com