Multi-station top-suction type exhaust and dust processing device with function of automatic station conversion

A dust collection device and multi-station technology, applied in the direction of dust removal, separation of dispersed particles, chemical instruments and methods, etc., can solve problems such as difficulty in collecting unorganized dust, environmental dust pollution, narrow operating space, etc., and achieve excellent performance , high degree of automation and high collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

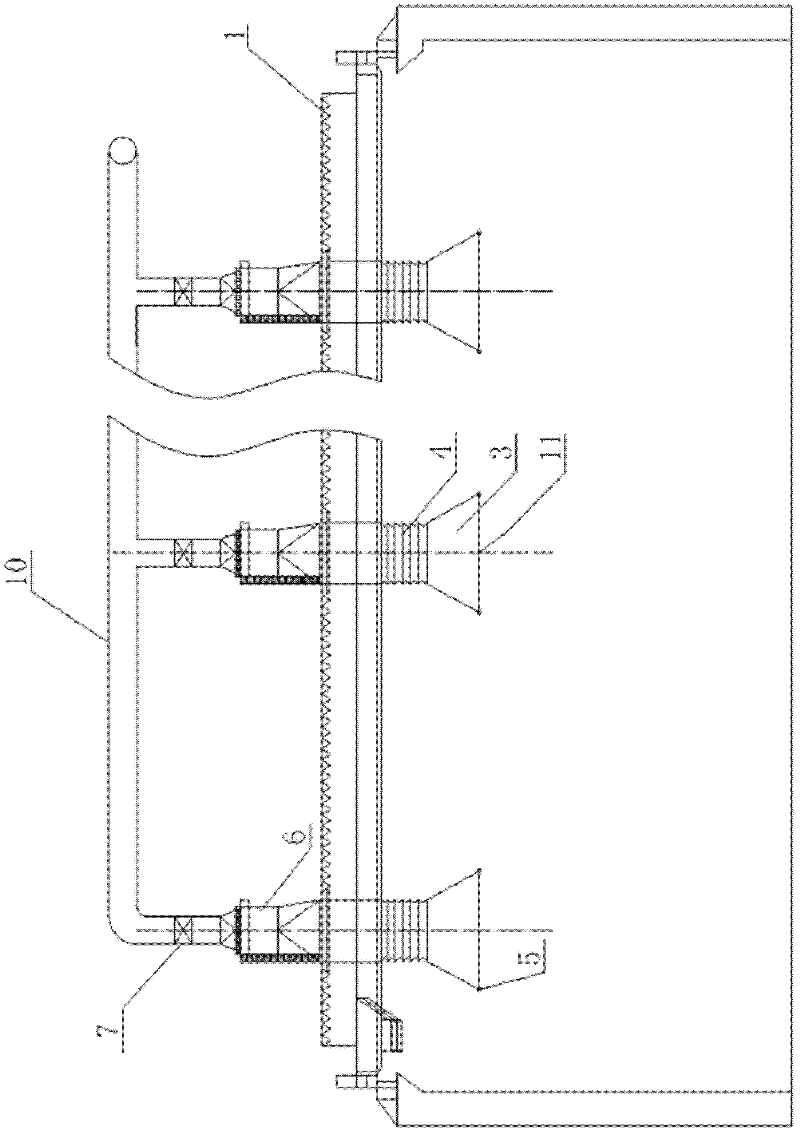

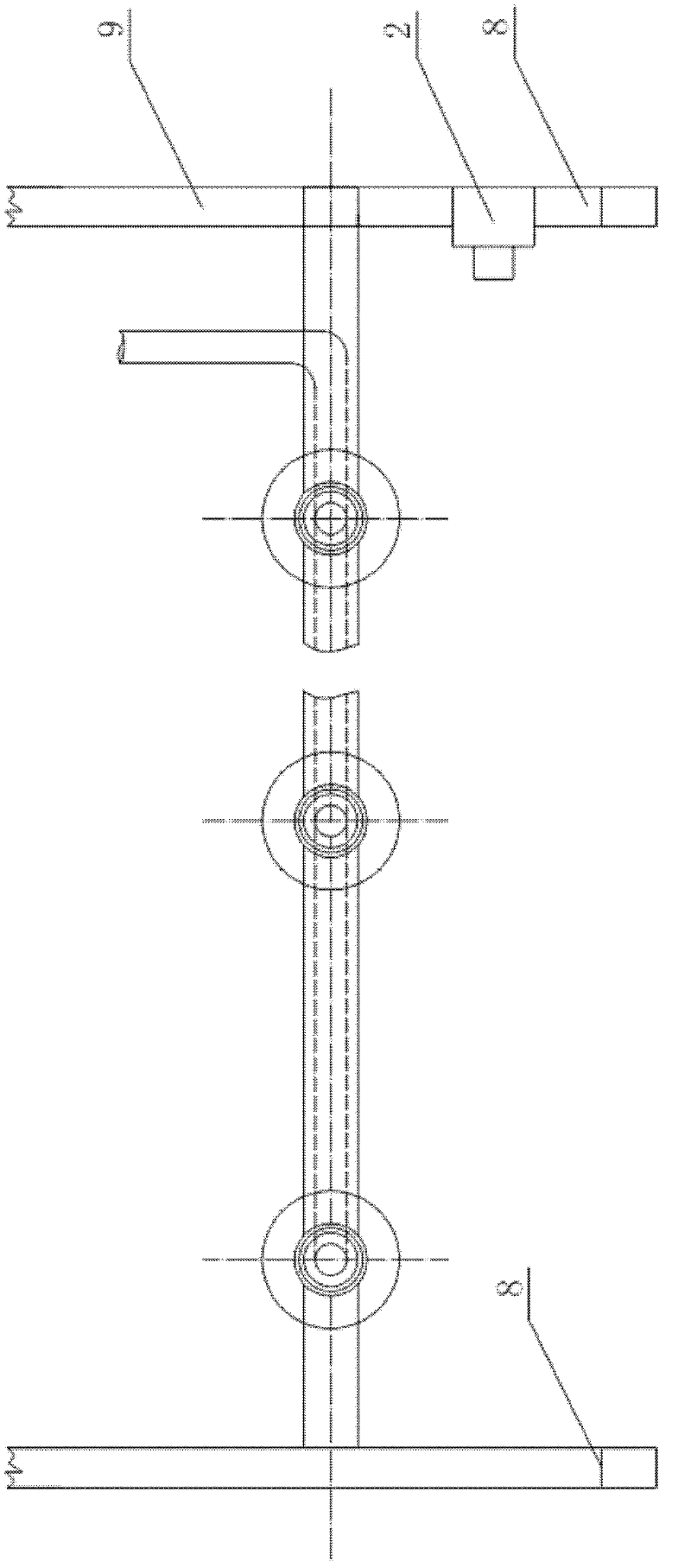

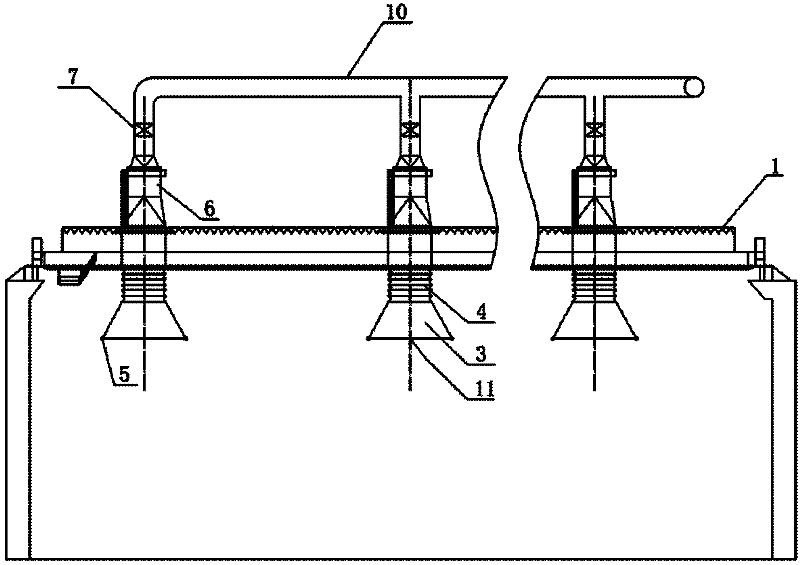

[0021] Example: Combined figure 1 , 2 , the track 9 is laid on the tall cement column or metal support in the workshop, the driving car 1 driven by the power mechanism 2 can walk on the track 9, and the travel switch 8 is arranged on the track to determine the stop position of the driving car 1; There are three or four dome suction hoods 3, the upper end of which is connected with an air outlet pipe 6 and a control valve 7 is arranged in the pipe, and the lower end of each top suction hood 3 is provided with an exhaust gas inlet 11 . A plurality of air outlet ducts 6 are connected in parallel to the main air duct 10 and the main air duct 10 communicates with the bag filter system arranged outside the workshop, and a photoelectric switch 5 is provided on the edge of the lower port of the top-suction hood.

[0022] The upper end of the dust collection cover 3 is connected with the air outlet duct 6 through the bellows 4, and the bellows can adjust the height of the dust collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com