Solidification/stabilization method for mercury-containing hazardous waste

A hazardous waste and stabilization technology, which is applied to the treatment of mercury-containing hazardous wastes, can solve problems such as low mercury adsorption capacity, and achieve the effects of simple operation process, high efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

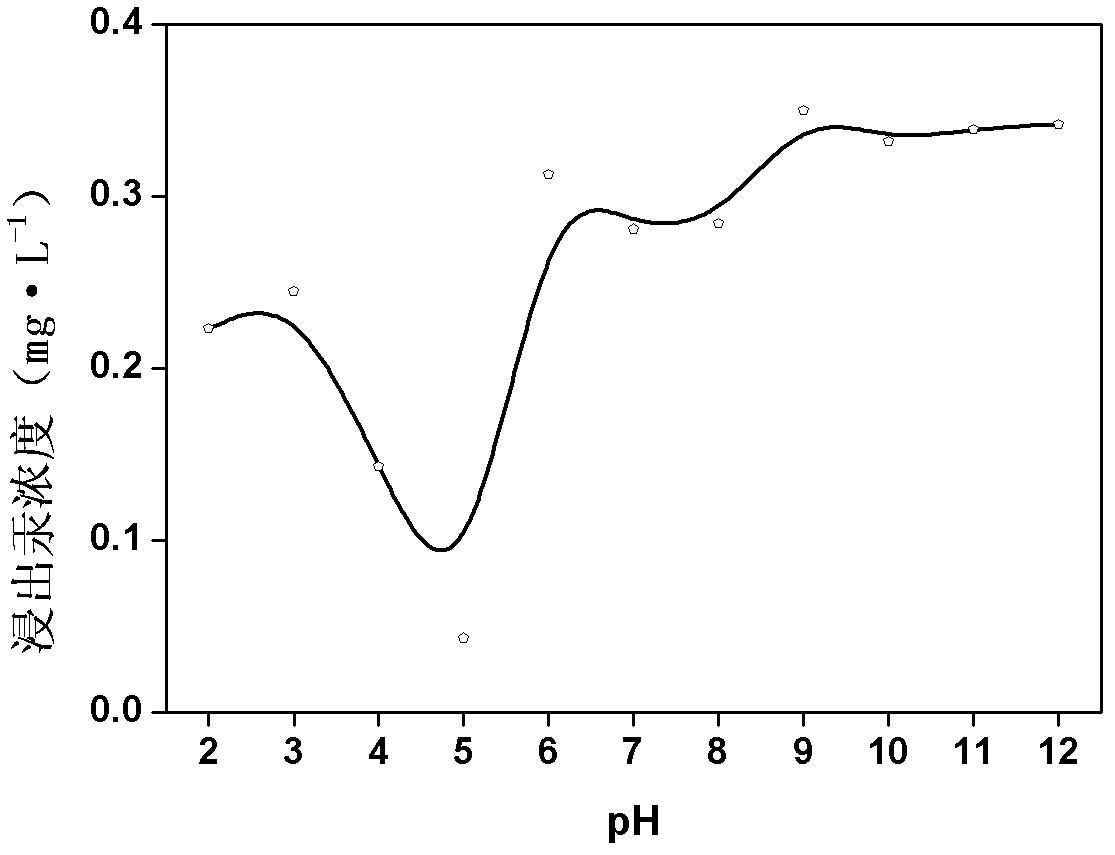

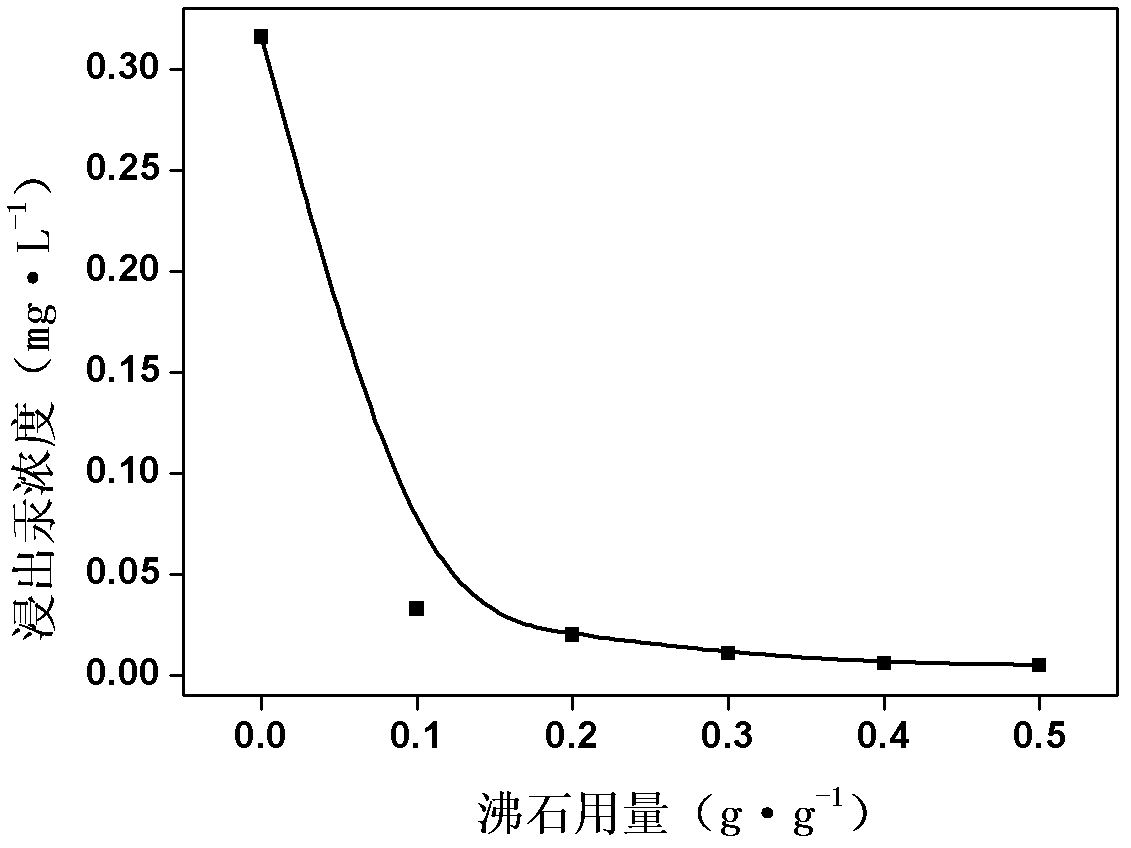

[0022] 1) Preparation of mercapto-functionalized zeolite: according to the mass g of natural clinoptilolite and 0.1mol L -1 The volume mL ratio of the hydrochloric acid solution is 1:5, soak the natural clinoptilolite in 0.1mol·L -1 HCl solution, heated at 80°C for 24h, centrifuged and filtered, the solid material was rinsed with deionized water, and the cleaning solution was tested with silver nitrate until there was no white flocculent precipitate of silver chloride in the cleaning solution, and dried at 60°C Overnight, obtain hydrogen type zeolite; According to the quality g of hydrogen type zeolite: the quality g of 3-mercaptopropyltrimethoxysilane: the volume mL ratio of anhydrous toluene is 1: 1: 50, mix hydrogen type zeolite and 3-mercapto Propyltrimethoxysilane was added to anhydrous toluene, refluxed at 110°C for 10 hours, and centrifuged to filter. The mercapto-functionalized zeolite wool obtained was washed with toluene and ethanol successively, and then eluted in e...

Embodiment 2

[0026] Embodiment 2: described step 3) solidification / stabilization operation of mercury-containing hazardous waste: according to the mercury content value obtained in step 2), 10.0g contains mercury 100mg·kg -1 Add 50mL of deionized water and 1g of mercapto-functionalized zeolite to the mercury-containing hazardous waste, adjust the pH to 4, and the rest are the same as in Example 1

[0027] The measurement results showed that the concentration of mercury leached from mercury-containing hazardous waste was changed from the initial 4.14mg·L -1 reduced to 0.02mg·L -1 , which is lower than the leached mercury concentration of 0.1mg·L stipulated in the Chinese national standard GB5085.3-2007 -1 The standard value, the curing efficiency is greater than 99%.

Embodiment 3

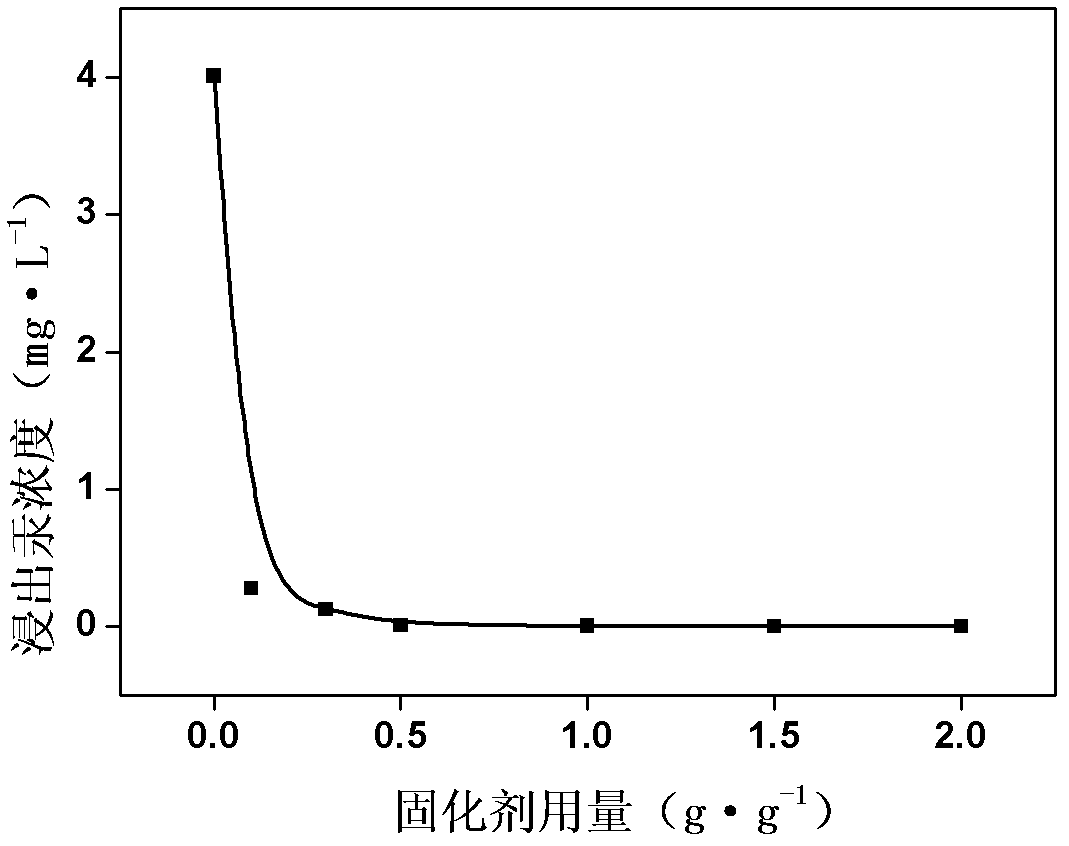

[0028] Embodiment 3: described step 3) solidification / stabilization operation of mercury-containing hazardous waste: according to the mercury content value obtained in step 2), 10.0g contains mercury 1000mg·kg -1 Add 50mL of deionized water and 10g of mercapto-functionalized zeolite to the mercury-containing hazardous waste, adjust the pH to be 6, and the rest are the same as in Example 1

[0029] The measurement results showed that the concentration of mercury leached from mercury-containing hazardous waste was changed from the initial 13.92mg·L -1 reduced to 0.09mg·L -1 , which is lower than the leached mercury concentration of 0.1mg·L stipulated in the Chinese national standard GB5085.3-2007 -1 The standard value, the curing efficiency is greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com