Method for manufacturing high-hardness and high-abrasion-resistant pre-bending machine lower die

A high wear resistance, pre-bending machine technology, applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of large deformation, hardness and wear resistance can not meet the requirements, surface cracks easily, to improve The effect of hardness, cost-effectiveness, and reduced possibility of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

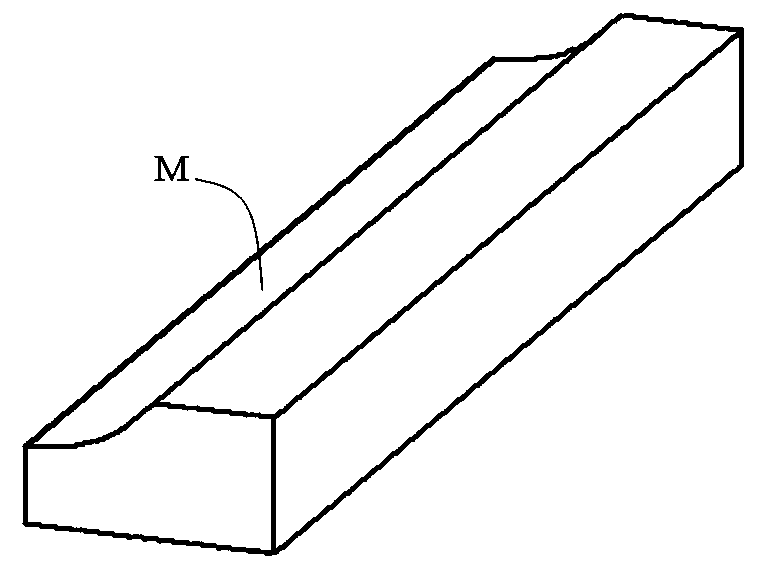

Image

Examples

Embodiment 1

[0045] A kind of method of manufacturing high hardness, high wear resistance pre-bending machine lower mold of this embodiment, its specific production steps are:

[0046] (1) Preparation of raw materials for the lower die of the pre-bending machine: the forging blank meeting the requirements of the present invention, its components are calculated by weight percentage: C: 0.38-0.45%, Si: 0.17-0.37%, Mn: 0.50-0.80%, S: ≤0.035%, P: ≤0.035%, Cr: 1.70-2.20%, Ni: ≤0.030%, Cu: ≤0.030%, Mo: 0.15-0.25%, and the rest is Fe. The forging used in this example Blank, its composition by weight percentage is: C: 0.41%, Si: 0.25%, Mn: 0.65%, S: 0.030%, P: 0.028%, Cr: 2.00%, Ni: 0.030%, Cu: 0.030% , Mo: 0.20%, the rest is Fe;

[0047] (2) Annealing treatment of forged blanks: anneal the forged blanks in step (1) through an annealing furnace to reduce hardness and improve cutting performance. The annealing temperature is 760°C and the annealing time is 5 hours. After cooling to 400°C in the f...

Embodiment 2

[0054] A kind of method of manufacturing high hardness, high wear resistance pre-bending machine lower mold of this embodiment, its specific production steps are:

[0055] (1) Preparation of raw materials for the lower die of the pre-bending machine: the forging blank used in this example has the following components by weight percentage: C: 0.45%, Si: 0.37%, Mn: 0.80%, S: 0.030%, P: 0.028%, Cr: 2.10%, Ni: 0.030%, Cu: 0.030%, Mo: 0.25%, and the rest is Fe;

[0056] (2) Annealing treatment of forged blank: anneal the forged blank in step (1) through an annealing furnace to reduce hardness and improve machinability. The annealing temperature is 770°C, and the annealing time is 4 hours. After cooling to 400°C in the furnace, air cooling is carried out. At this time, the hardness of the forged blank is HB 245;

[0057] (3) Preliminary processing of the forging blank: After step (2) annealing treatment, the forging blank is made into a workpiece with a single-sided allowance. Cut...

Embodiment 3

[0063] A kind of method of manufacturing high hardness, high wear resistance pre-bending machine lower mold of this embodiment, its specific production steps are:

[0064] (1) Preparation of raw materials for the lower die of the pre-bending machine: the forging blank used in this example has the following components by weight percentage: C: 0.38%, Si: 0.17%, Mn: 0.50%, S: 0.030%, P: 0.028%, Cr: 2.20%, Ni: 0.030%, Cu: 0.030%, Mo: 0.15%, and the rest is Fe;

[0065] (2) Annealing treatment of forged blanks: anneal the forged blanks in step (1) through an annealing furnace to reduce hardness and improve cutting performance. The annealing temperature is 750°C and the annealing time is 6 hours. After cooling to 400°C in the furnace, air cooling is carried out. At this time, the hardness of the forged blank is HB 220;

[0066] (3) Preliminary processing of the forging blank: After step (2) annealing treatment, the forging blank is made into a workpiece with a single-sided allowanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com