Stainless steel sealing specially-shaped electrode for resistance spot welding

A resistance spot welding and stainless steel technology, applied in the field of electrodes, can solve the problem that straight rod electrodes cannot be spot welded, and achieve the effect of reliability and simple replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

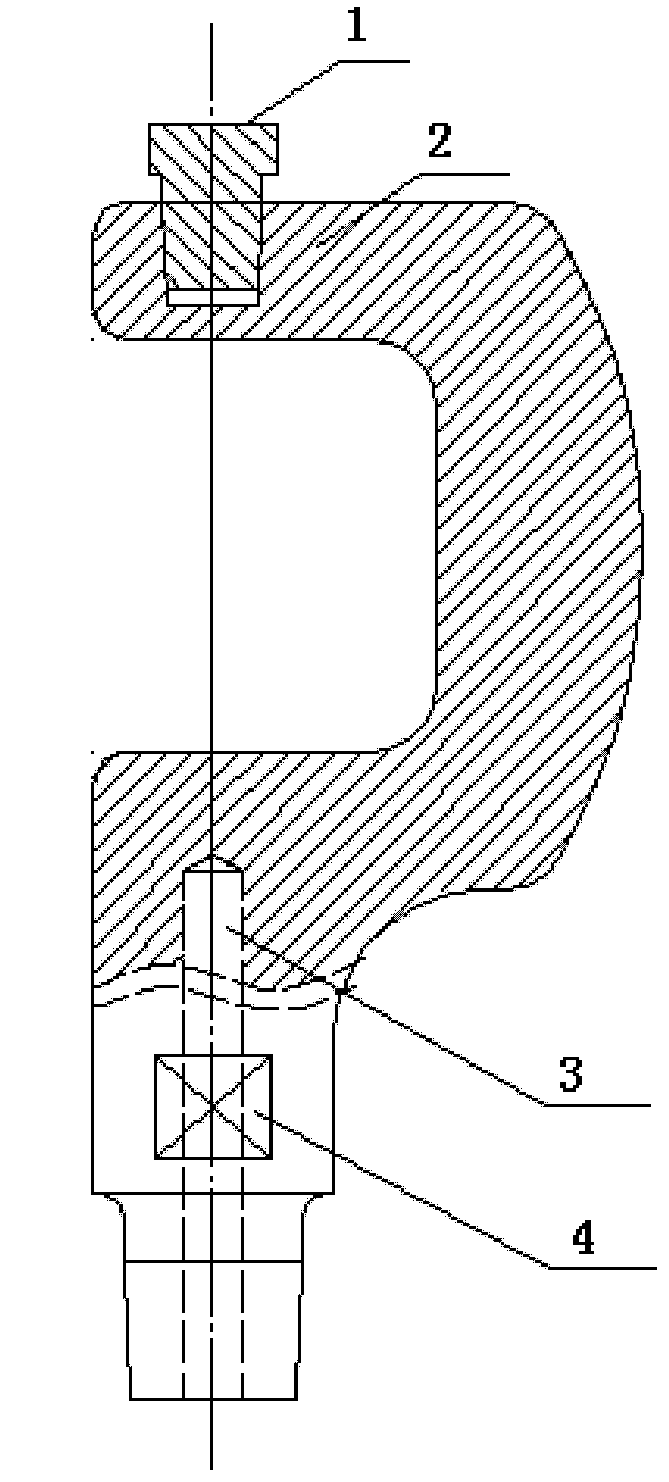

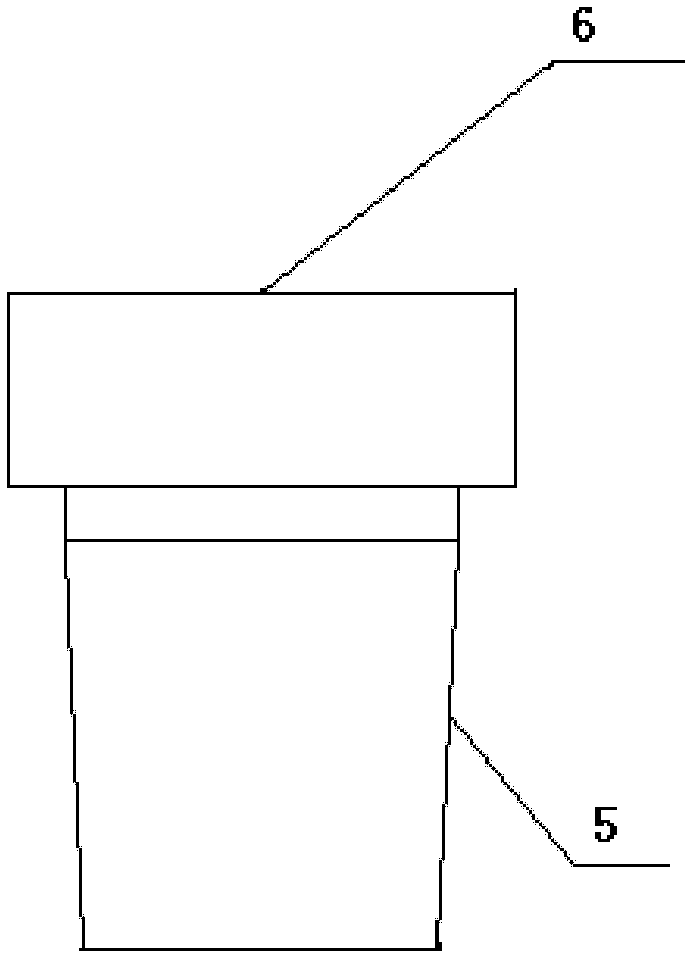

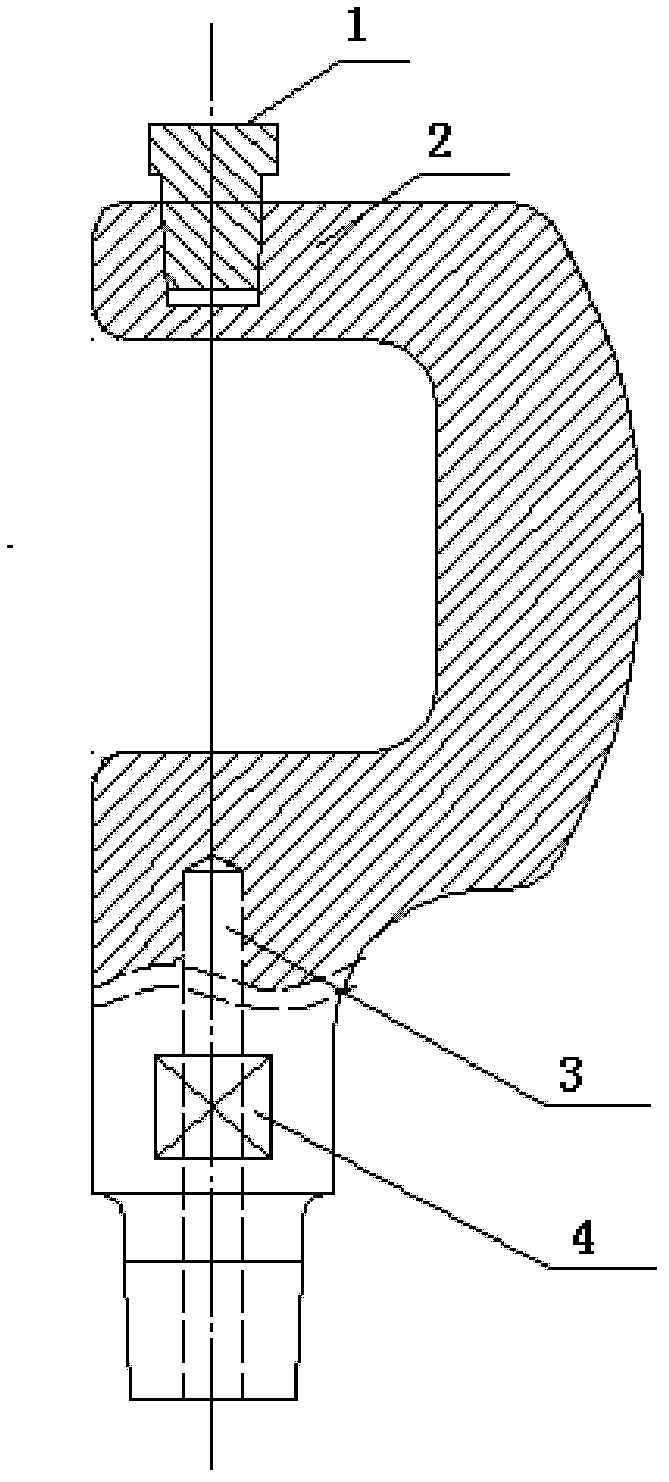

[0009] refer to figure 1 , the main body 2 is processed into a half-shaped I-shaped with CrZrCu at one time, the Vickers hardness is greater than 145, the Rockwell hardness is greater than 75, and the electrical conductivity is greater than 70%. It is softened at a high temperature. The high temperature softening temperature is 500 degrees Celsius. The standard conforms to JISSZ3234. The upper end of the main body is interference-fitted with a replaceable straight-rod circular electrode head 2 , the lower end of the main body is T-shaped with a taper, and a cooling water hole 3 is opened in the center. The main body is equipped with a disassembly position, and a plane 4 of 15mmX17mm is processed at the position of the round bar of Φ35, and two places are processed symmetrically front and back, so as to realize the replacement of the main body and the straight electrode. The conical surface of the main body and the electrode bank of the spot welding equipment must be protected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com