Method for driving a plurality of flyers by using laser and implementation device

A laser-driven, flying piece technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of laser-driven flying piece technology limitations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

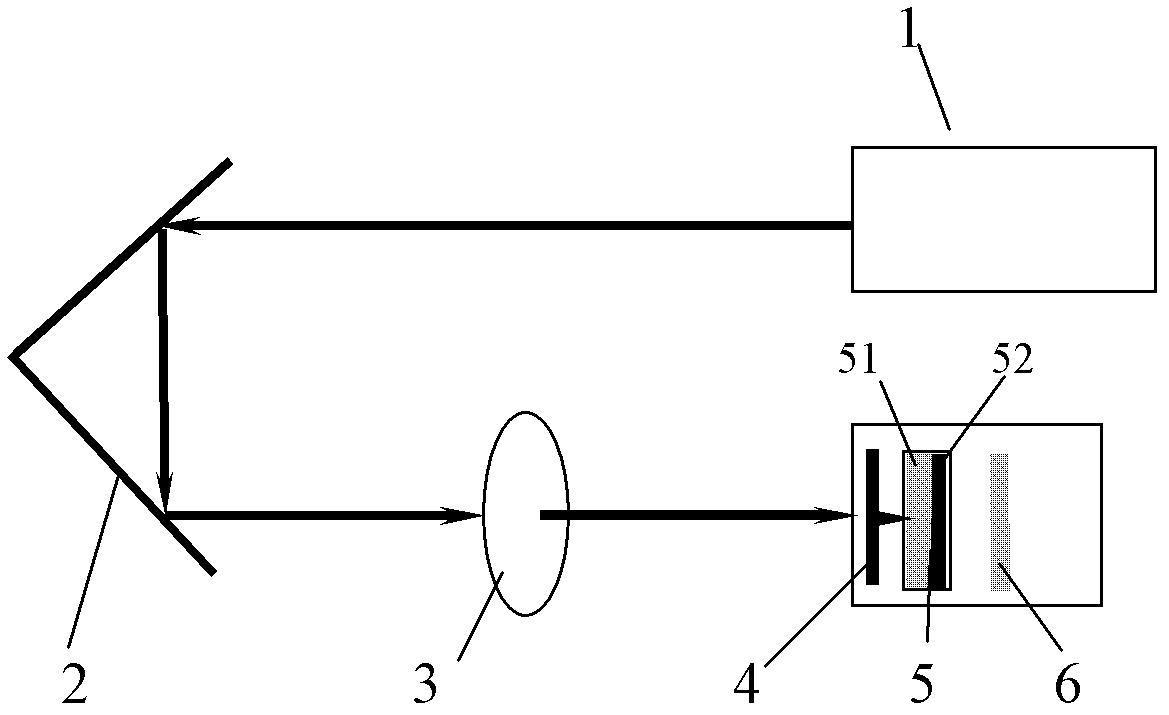

Method used

Image

Examples

experiment example 1

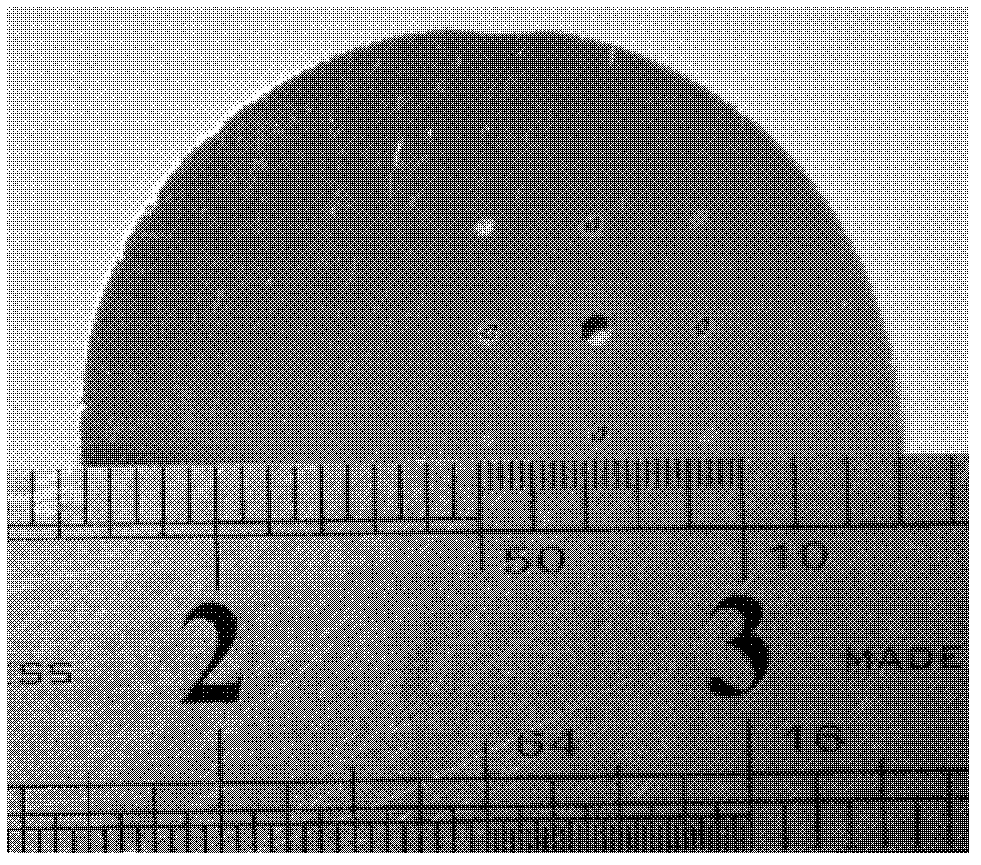

[0023] Quartz glass with a diameter of 40 mm and a thickness of 3 mm was ultrasonically cleaned with deionized water and absolute ethanol for 10 minutes to remove residual organic pollutants on the surface of the material, and then dried naturally in the air after cleaning. One surface of the cleaned quartz glass is coated with aluminum by magnetron sputtering, the purity of aluminum is 99.9999%, and the thickness of the obtained aluminum film is 6 μm. Using a nanosecond pulse laser, the laser light with certain parameters is diffracted by an orthogonal grating to produce a series of point lights, and each point light is incident on the flyer target made of optical glass deposited with a metal film, so that the metal film The surface evaporates, gasifies and ionizes instantaneously to generate high-temperature and high-pressure plasma. Due to the constraints of optical glass, the high-pressure shock wave generated by the plasma acts on the metal film in front of the incident ar...

experiment example 2

[0026] The difference between Experimental Example 2 and Experimental Example 1 is that aluminum is adhered to one surface of the cleaned quartz glass by the adhesive film method, and the thickness of the aluminum film is 20 μm. Set the distance between the flyer target 5 and the impact target 6 to be 4 mm. Choose laser energy 320mJ, trigger frequency 1Hz, laser pulse width 6ns.

experiment example 3

[0028] The difference between Experimental Example 3 and Experimental Example 1 is that a layer of graphite with a thickness of 6 μm is deposited on one surface of the cleaned quartz glass by pulling method, and then aluminum is adhered on the graphite film by the adhesive film method, and the thickness of the aluminum film is 20 μm. Set the distance between the flyer target 5 and the impact target 6 to be 6 mm. Choose laser energy 280mJ, trigger frequency 5Hz, laser pulse width 6ns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com