Aluminum alloy flux-cored wire forming machine

A technology of flux-cored welding wire and forming machine, applied in welding medium, welding equipment, metal processing equipment and other directions, can solve the problems of inability to guarantee filling rate, waste of production time, complicated equipment operation, etc., and achieve compact structure, energy saving, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

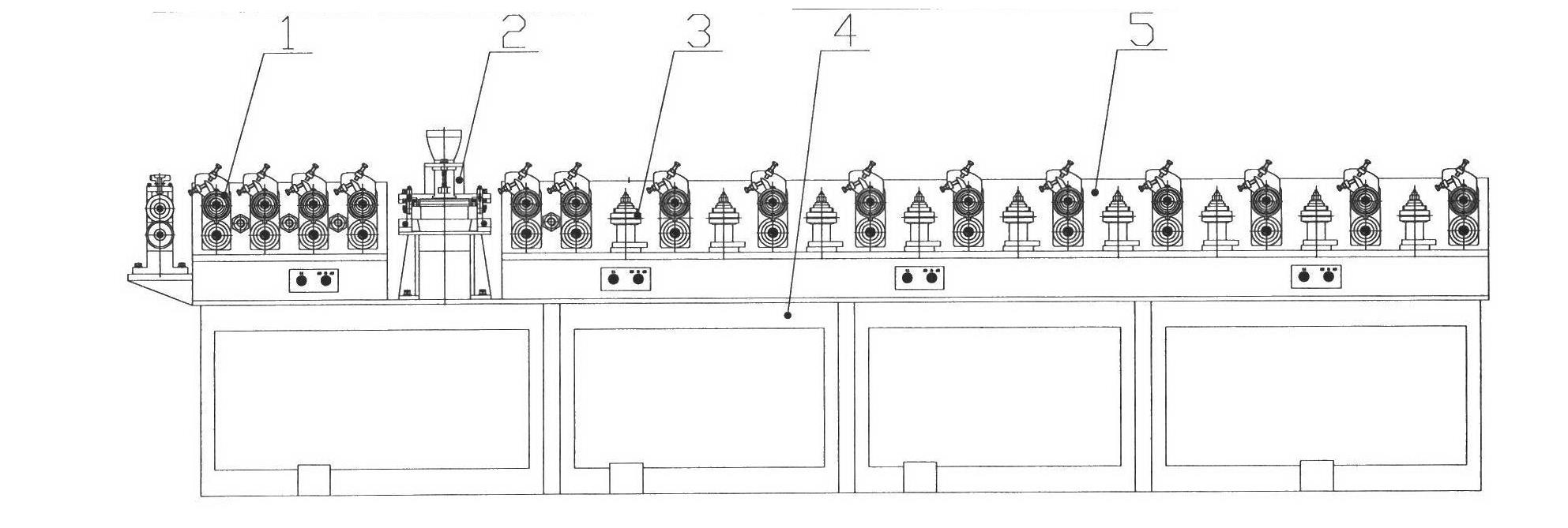

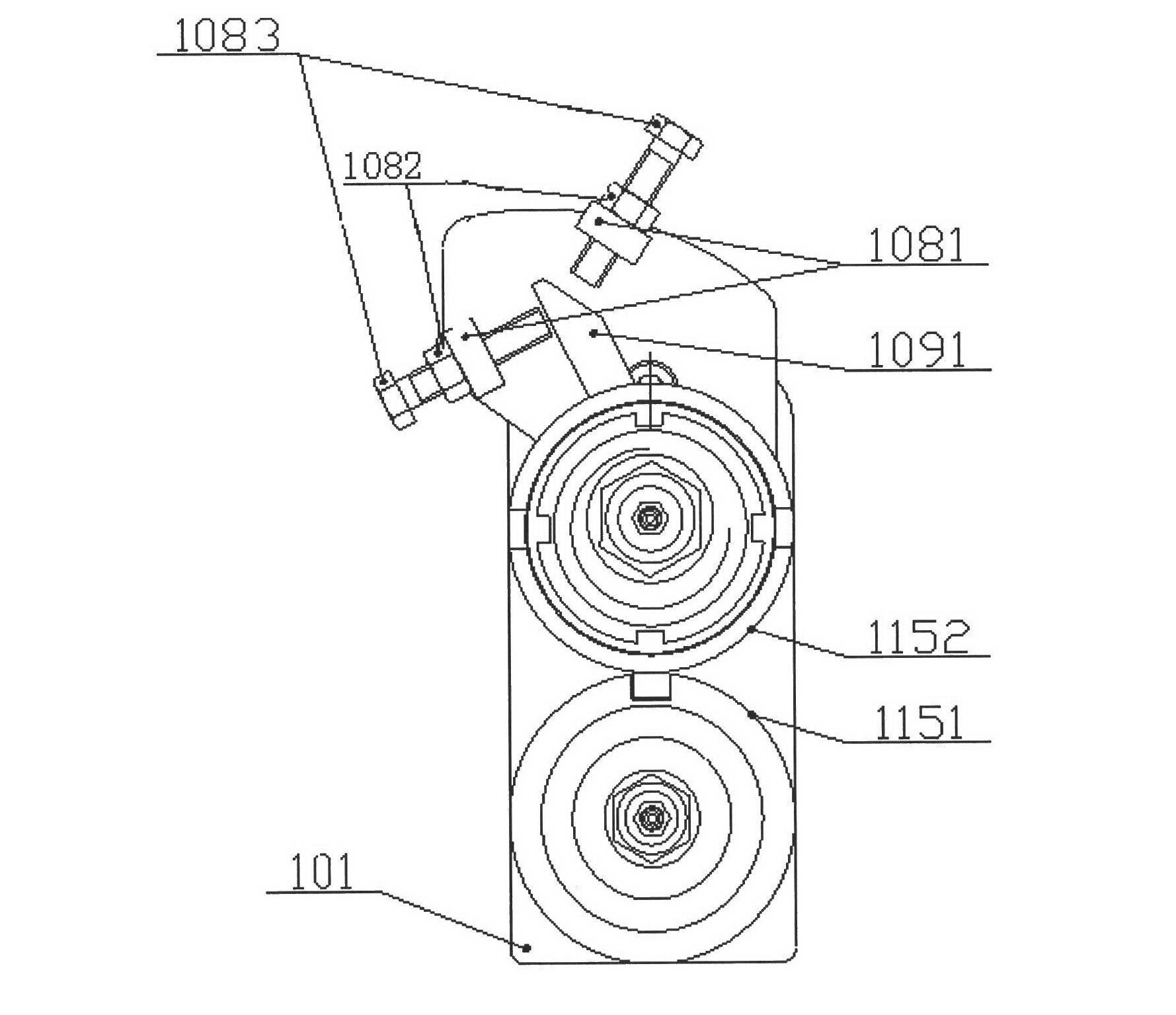

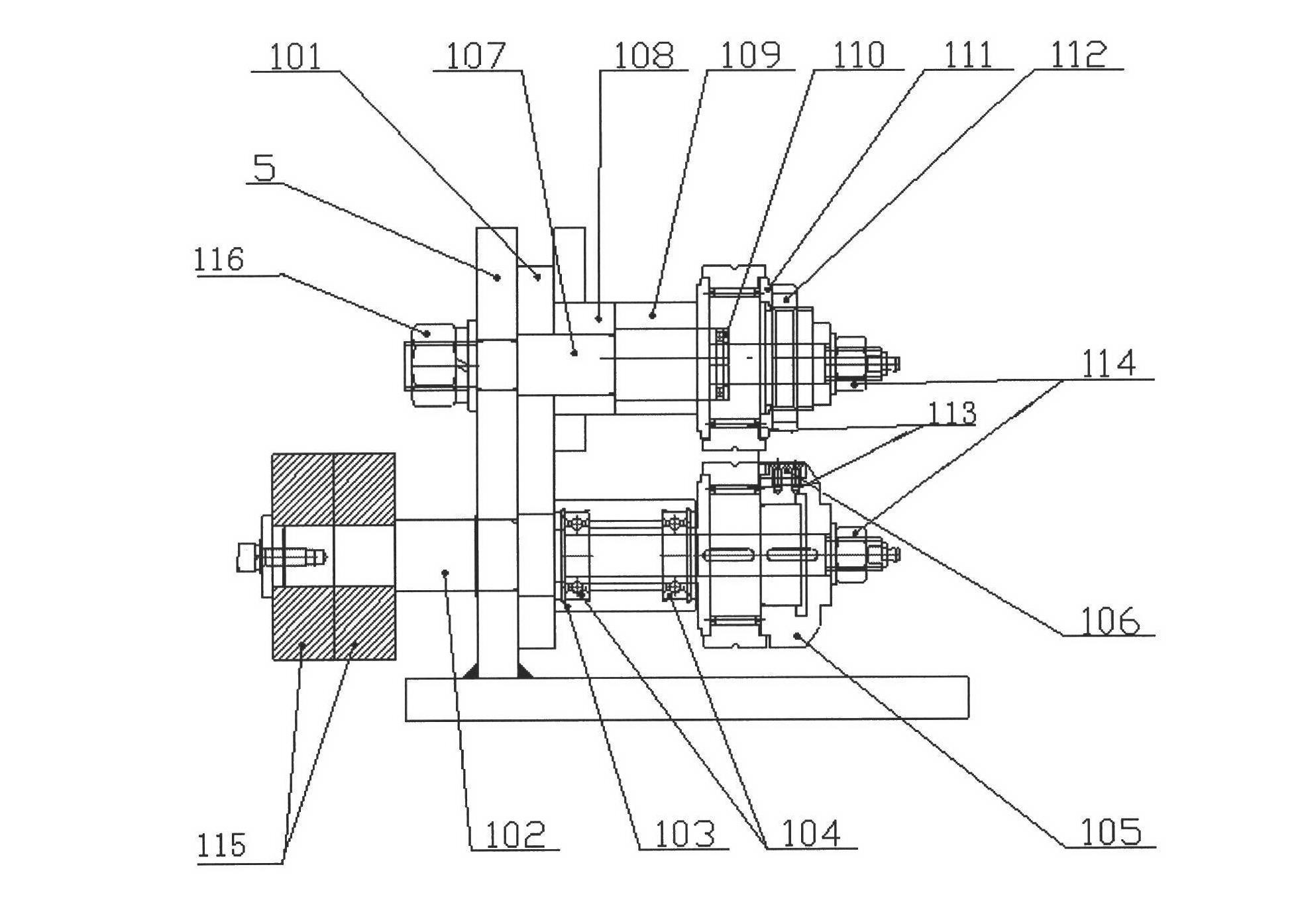

[0036] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6. The aluminum alloy flux-cored wire forming machine provided by the present invention includes a deformation device, a powder adding device, a closing device and a diameter reducing device. side; the deforming device is 2 to 4 groups of adjacent vertical rolls 1, the closing device is 1 to 2 groups of adjacent vertical rolls 1 and a set of horizontal rolls 3 and 1 set of vertical rolls 1, and the reducing device is 1-8 groups of horizontal rolls 3 and 1-8 groups of vertical rolls 1. The present invention is provided with frame 4 and roll support plate 5, and deformation device, powder adding device, closing device, reducing device and roll support plate 5 are arranged on frame 4. Wherein, the vertical roll 1 includes two roll shafts, a first vertical roll shaft 102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com