Multi-stage anaerobic anoxic aerobic biological reaction tank

A biological reaction pool, anoxic and aerobic technology, applied in the field of biological pools, can solve the problems of increasing connecting pipelines or hydraulic equipment, difficult to reduce construction investment or operating costs, etc., to reduce operating costs, save carbon sources, and process processes. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

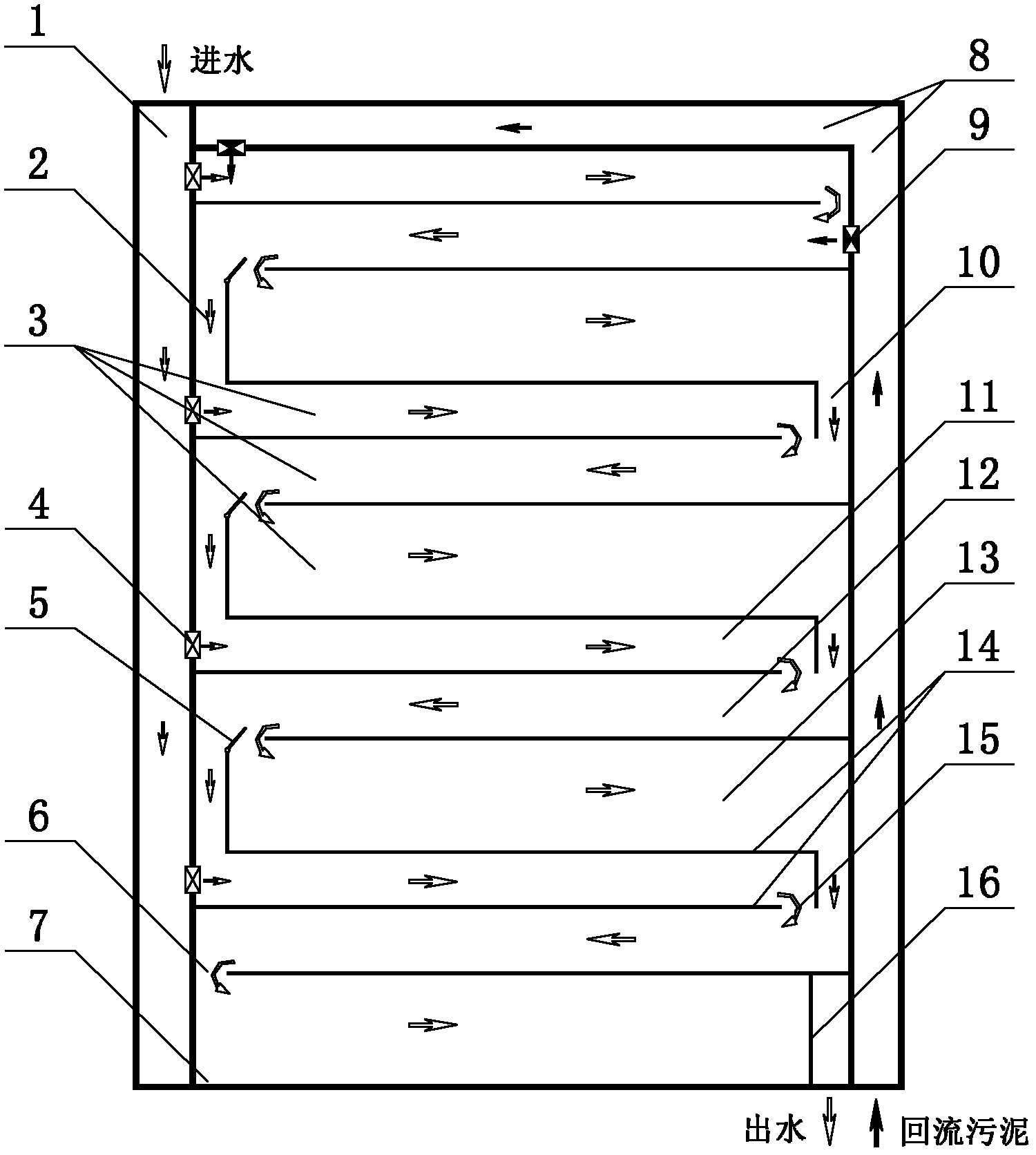

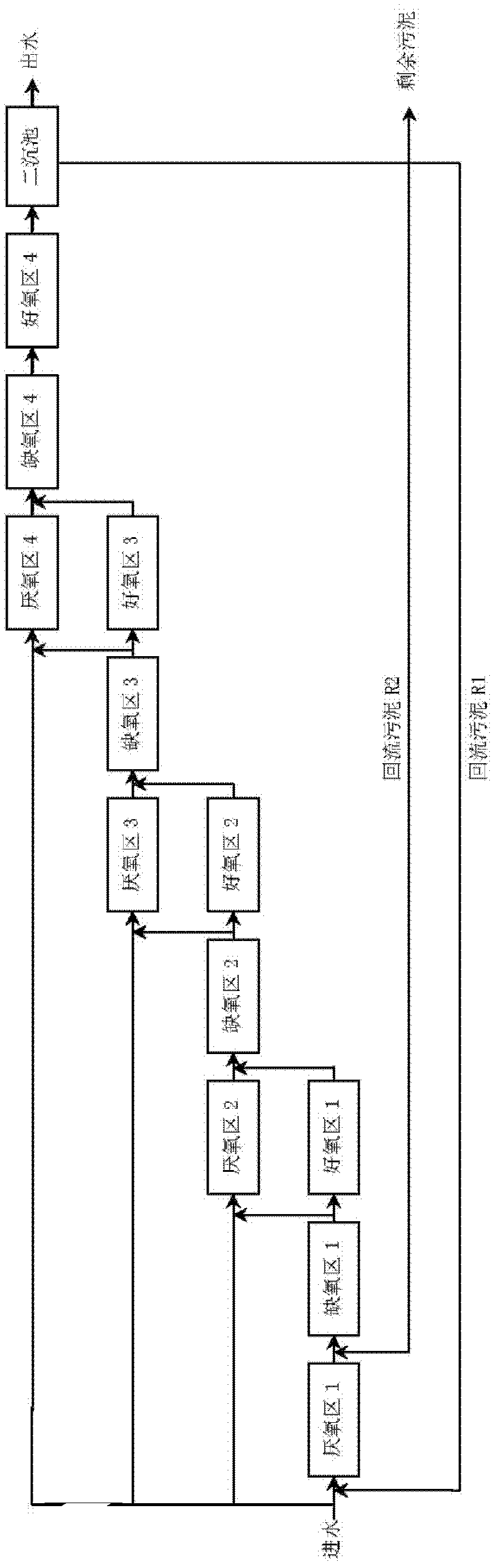

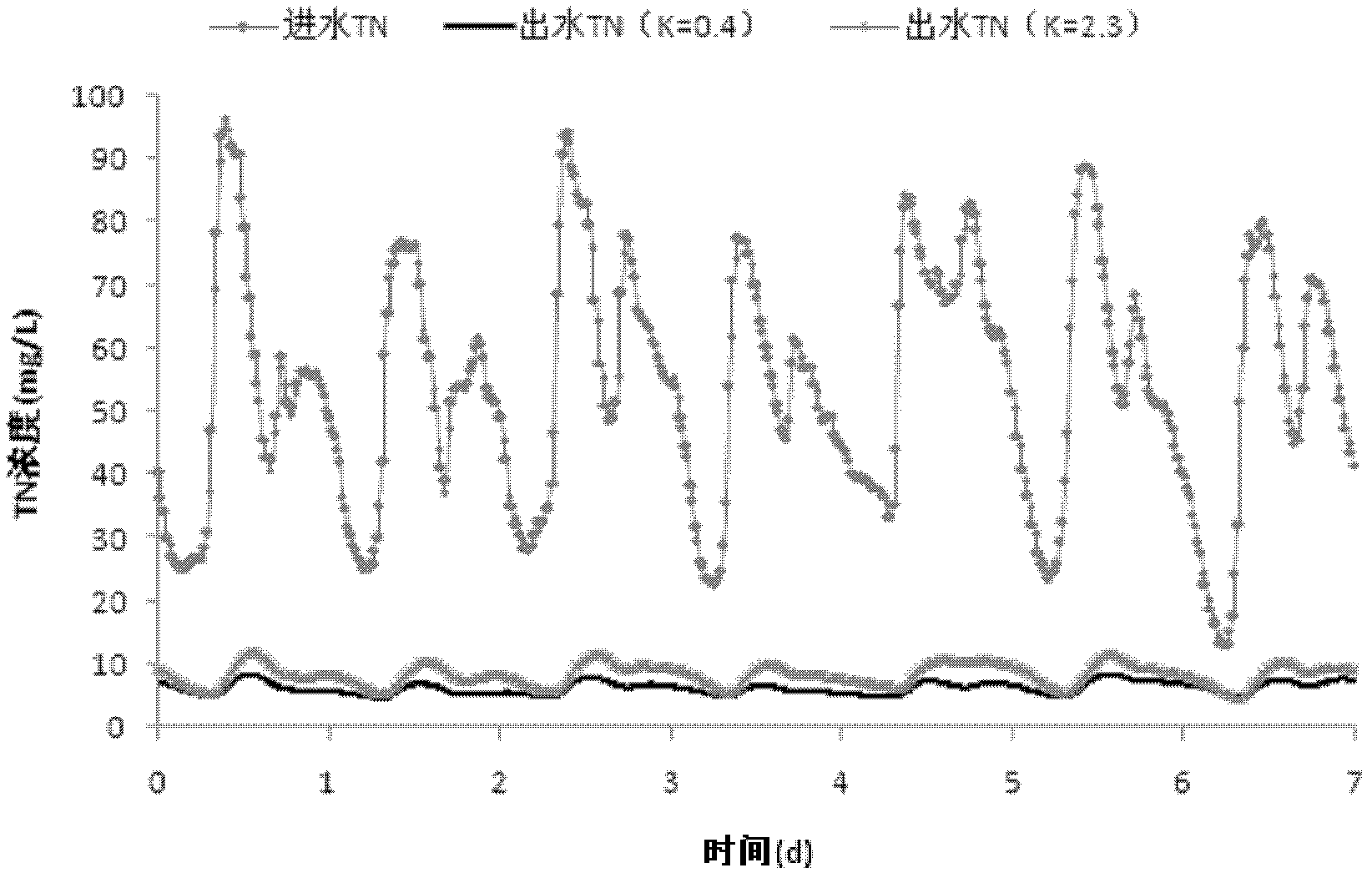

[0016] Below in conjunction with the preferred embodiments, the specific implementation provided according to the present invention is described in detail as follows: See the accompanying drawings for details, a multi-stage anaerobic anoxic aerobic biological reaction tank, including an anaerobic tank, an anoxic tank and An aerobic tank is a single-stage anaerobic-anoxic-aerobic biological reaction tank arranged in the order of anaerobic-anoxic-aerobic and interconnected, and the single-stage anaerobic-anoxic-aerobic biological reaction tank is connected along the direction of water flow M-level anaerobic-anoxic-aerobic biological reaction tanks, the first to (M-1) level aerobic tanks are respectively equipped with anoxic diversion ports, and the anoxic diversion ports are provided with shunt adjustment devices ; The tail end of the anoxic pool of this level is communicated with the head end of the aerobic pool of this level through the anoxic diversion port, and the tail end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com