Process technology aiming at strengthening treatment of waste water in chemical engineering centralizing area

A process technology and technology for concentrated areas, which are applied in the field of enhanced pretreatment of sewage in chemical concentration areas, can solve the problems of large changes in water quality and water quantity, inability to adapt to the impact of influent water quality, and low biodegradable B/C values. Achieve the effect of reducing wastewater toxicity, facilitating centralized management and improving B/C value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

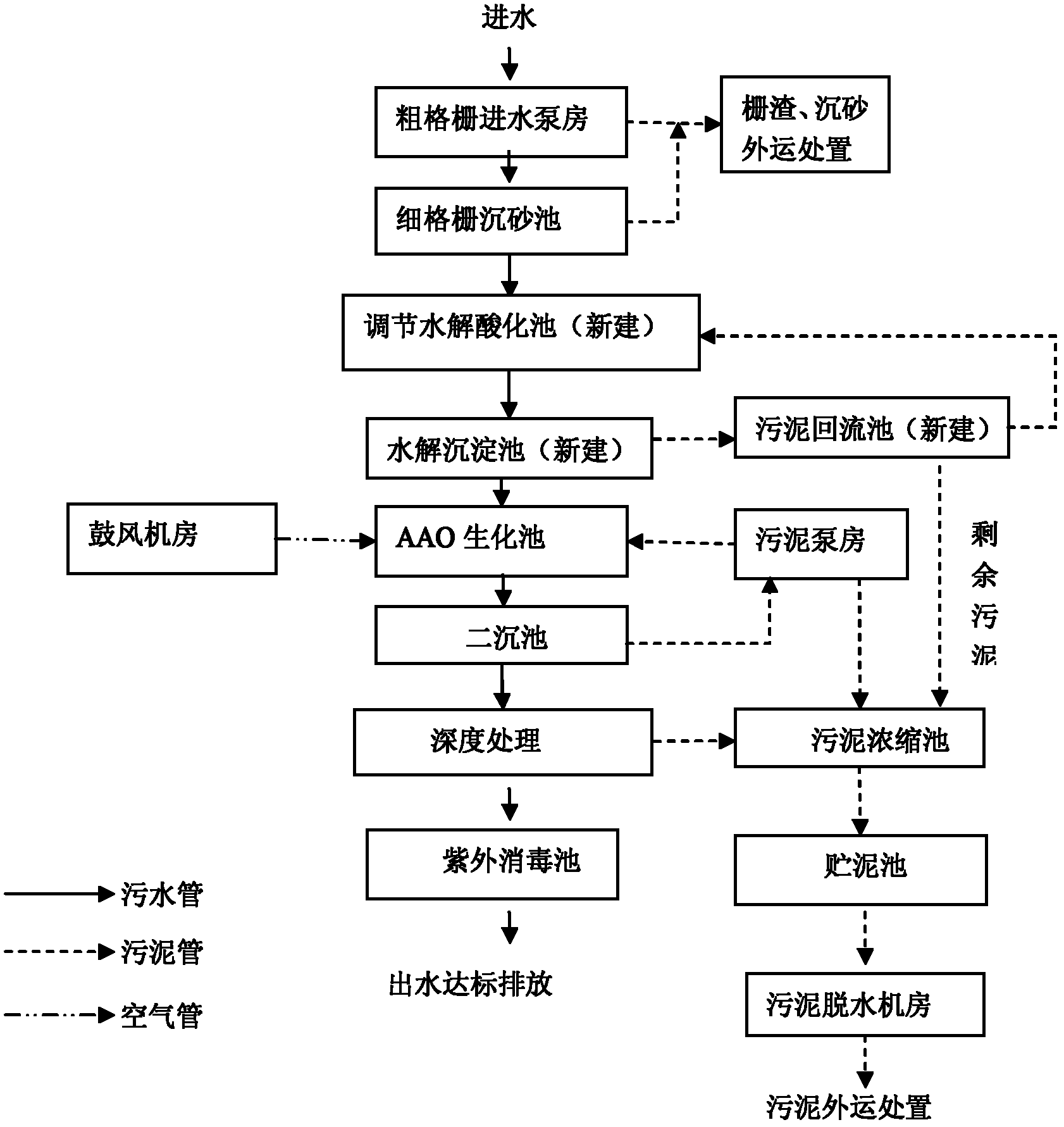

[0014] The sewage treatment process of the present invention is as figure 1 As shown, an enhanced pretreatment process is added between the first-level physical treatment (coarse grid inlet pump house-fine grid grit chamber) and the second-level biochemical treatment (AAO biochemical tank-secondary sedimentation tank), that is, the adjustment Hydrolytic acidification tank - hydrolysis sedimentation tank - sludge return tank.

[0015] The regulating hydrolysis acidification pool adopts the oxidation ditch pool type, and 2 to 5 low-speed submersible flowmakers are arranged in sections in the pool to generate circulating water flow in the pool and prevent sludge deposition in the pool. The circulating water flow is mixed, so as to play a homogeneous role. At the same time, the anaerobic activated sludge in the pool is used to degrade th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com