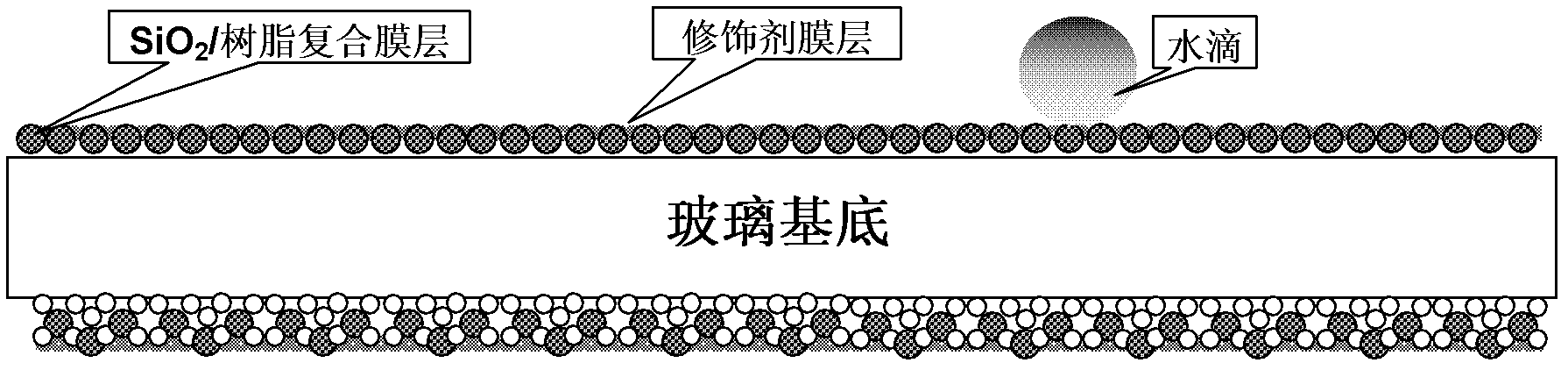

A kind of modified nano-sio2 sol, its preparation method and its application method on automobile glass

An automotive glass and sol technology, applied in the field of modified nano-SiO2 sol, can solve the problems of poor anti-fog aging, poor wear resistance of super-hydrophobic film, difficult to combine super-hydrophobicity and light transmittance, etc. Anti-fog performance, excellent wear resistance, good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1) Measure 50ml of absolute ethanol, 3ml of concentrated ammonia water, 4ml of tetraethyl orthosilicate, and stir at 150r / min for 90min at 60°C to obtain SiO 2 Sol; Then add Dow 350 curing agent in Dow epoxy resin 301 with the ratio of 28wt%, stir to SiO 2 Add 0.5% epoxy resin to the sol, and continue to stir at 300r / min for 30min to obtain a uniform resin / SiO 2 Sol.

[0056] 2) Measure 50ml of absolute ethanol, 3ml of concentrated ammonia water, and 4ml of tetraethyl orthosilicate, and stir at 150r / min at 60°C for 90min after sealing to obtain a uniform SiO 2 Sol A: Measure 50ml of absolute ethanol, 1.5ml of concentrated ammonia water, and 1.5ml of tetraethyl orthosilicate, seal and stir at 250r / min for 90min at 60°C to obtain a uniform SiO 2 Sol B.

[0057] 3) Add KH-550 to Sol A at a mass ratio of 0.5%, and stir at 150 r / min for 20 min at room temperature to obtain Sol C.

[0058] 4) Stir sol C at a stirring speed of 300r / min, and slowly add sol B at the same tim...

Embodiment 2

[0061] 1) Measure 50ml of absolute ethanol, 3ml of concentrated ammonia water, 4ml of tetraethyl orthosilicate, and stir at 150r / min for 90min at 60°C to obtain SiO 2 sol; then a 10% polyvinyl butyral resin / ethanol solution was added to SiO at a ratio of 1.0% 2 In the sol, continue to stir at 300r / min for 30min to obtain a uniform resin / SiO 2 Sol.

[0062] 2) Measure 50ml of absolute ethanol, 3ml of concentrated ammonia water, and 4ml of tetraethyl orthosilicate, and stir at 150r / min at 60°C for 90min after sealing to obtain a uniform SiO 2 Sol A: Measure 50ml of absolute ethanol, 1.5ml of concentrated ammonia water, and 1.5ml of tetraethyl orthosilicate, seal and stir at 250r / min for 90min at 60°C to obtain a uniform SiO 2 Sol B.

[0063] 3) Add KH-550 to Sol A at a mass ratio of 0.5%, and stir at 150 r / min for 20 min at room temperature to obtain Sol C.

[0064] 4) Stir sol C at a stirring speed of 300r / min, and slowly add sol B at the same time, adjust the stirring spee...

Embodiment 3

[0067]1) Measure 50ml of absolute ethanol, 3.5ml of concentrated ammonia water, 3.5ml of tetraethyl orthosilicate, and stir at 150r / min for 90min at 60°C to obtain SiO 2 sol; then a 10% polyvinyl butyral resin / ethanol solution was added to SiO at a ratio of 1.0% 2 In the sol, continue to stir at 300r / min for 30min to obtain a uniform resin / SiO 2 Sol.

[0068] 2) Measure 50ml of absolute ethanol, 3.5ml of concentrated ammonia water, and 3.5ml of tetraethyl orthosilicate. After sealing, stir at 150r / min for 90min at 60°C to obtain a uniform SiO 2 Sol A: measure 50ml of absolute ethanol, 2.5ml of concentrated ammonia water, and 1.5ml of tetraethyl orthosilicate, seal and stir at 250r / min for 90min at 60°C to obtain a uniform SiO 2 Sol B.

[0069] 3) Add KH-550 to Sol A at a mass ratio of 0.5%, and stir at 150 r / min for 20 min at room temperature to obtain Sol C.

[0070] 4) Stir sol C at a stirring speed of 300r / min, and slowly add sol B at the same time, adjust the stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com