Fireproofing sealing material

A technology of fireproof sealing and resin, applied in the field of sealing materials, can solve the problems of poor water resistance, fireproof performance, physical and chemical properties, etc., and achieve good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

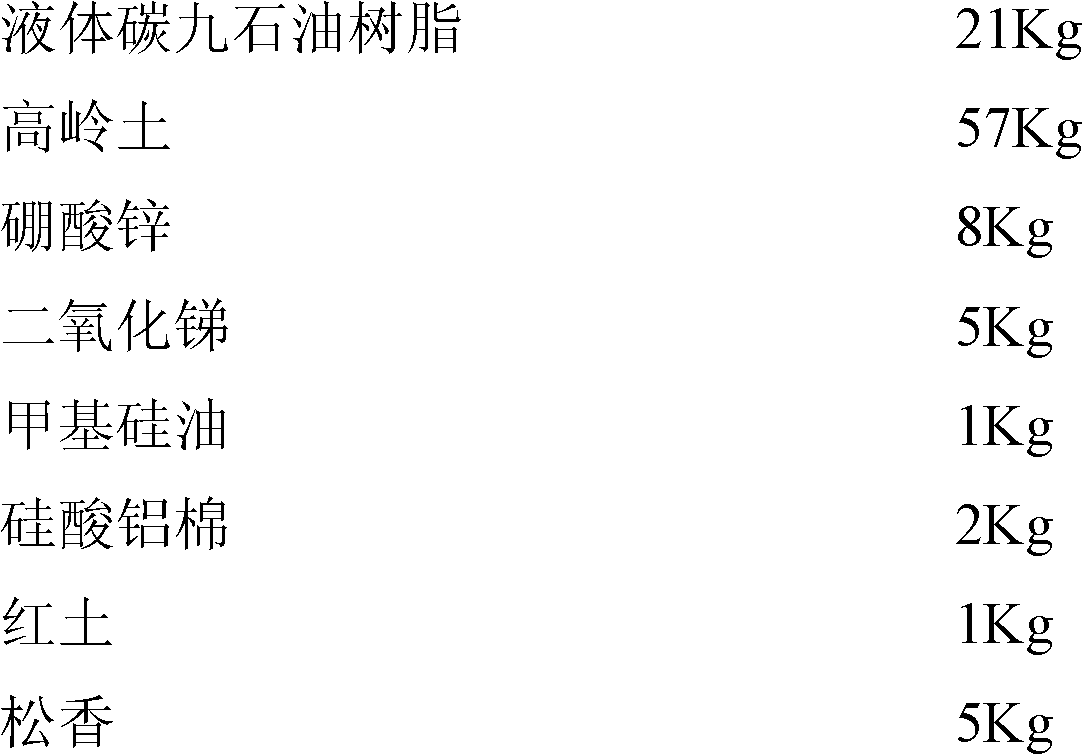

[0024] Weigh each composition according to the following ratio:

[0025]

[0026] First take the resin (liquid carbon nine petroleum resin), additives (methyl silicone oil), tackifier (rosin) and mix and stir for 20 minutes to prepare the bonding resin; then the filler (kaolin and red clay), flame retardant (zinc borate and Antimony dioxide), anticracking fiber (aluminum silicate wool) were mixed and stirred for 30 minutes to obtain a mixed powder; the prepared bonding resin and mixed powder were added to a kneader and kneaded for 30 minutes; the kneaded The plastic solid is put into an extruder for extrusion molding, and the fireproof plugging material is obtained.

Embodiment 2

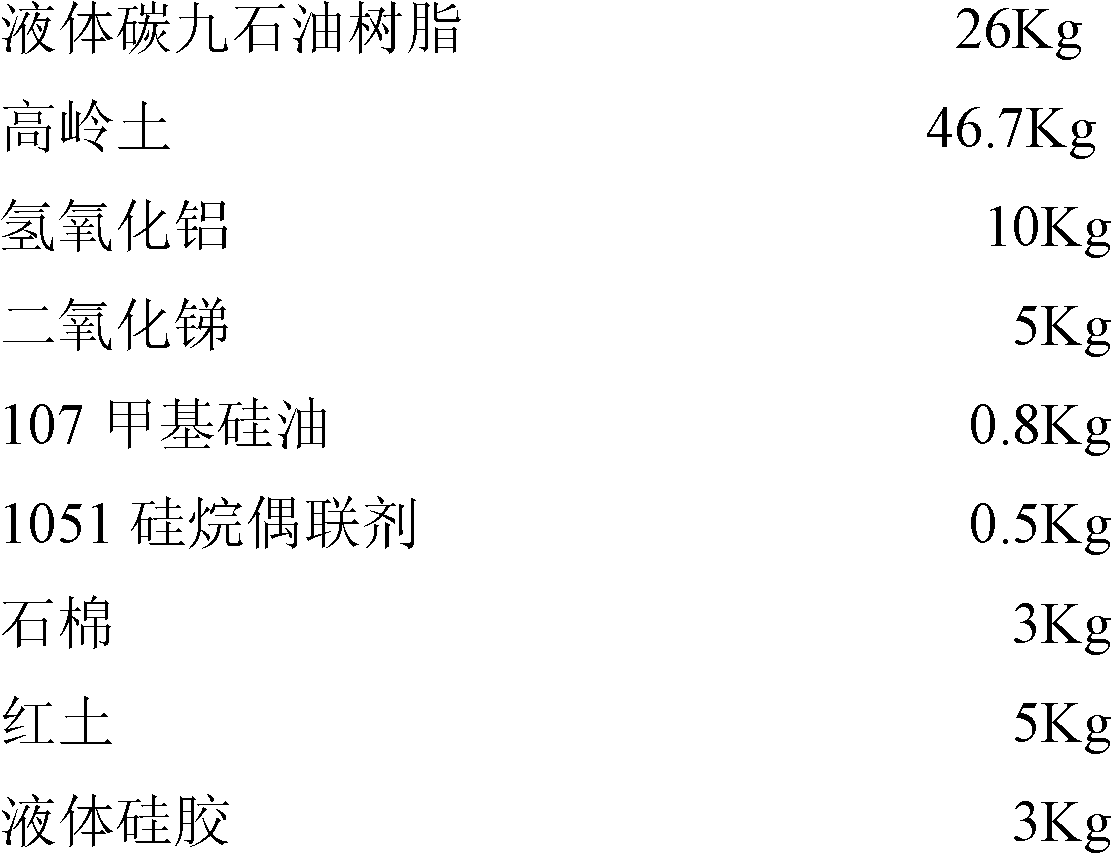

[0028] Weigh each composition according to the following ratio:

[0029]

[0030] The preparation method of this embodiment is the same as that described in Example 1.

Embodiment 3

[0032] Weigh each composition according to the following ratio:

[0033]

[0034] The preparation method of this embodiment is the same as that described in Example 1.

[0035] According to the detection standard of fireproof sealing material: GB23864-2009 detects the fireproofness obtained by the present invention

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com