High-porosity porous ceramic and preparation method thereof

A technology of porous ceramics and high porosity, which is applied to ceramic products, other household utensils, household utensils, etc., and can solve the problems of separate preparation process and complexity, and achieve the effect of increasing pore content, simplifying manufacturing process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

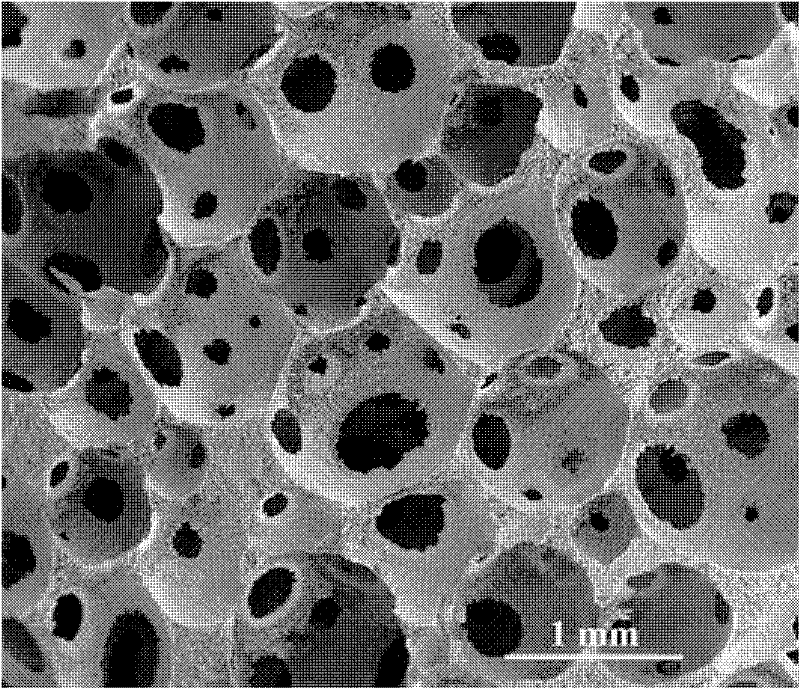

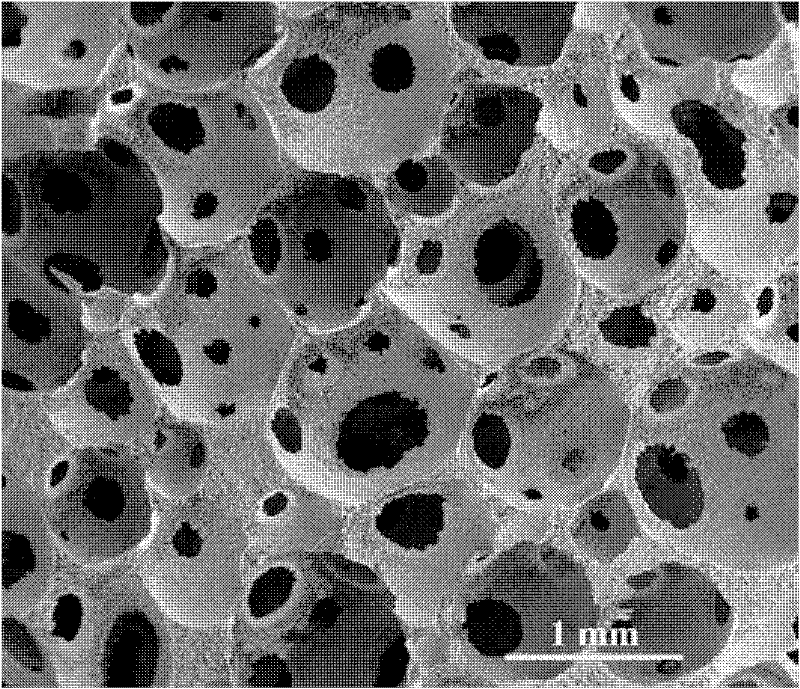

[0021] Embodiment 1: In this embodiment, a high-porosity porous ceramic has uniform spherical honeycomb pore structure units, the pore walls are connected to each other through porous windows, and the porosity P satisfies 90%<P<100%.

[0022] The beneficial effect of this embodiment is: the porosity of the high-porosity porous ceramics of this embodiment can reach more than 90%.

specific Embodiment approach 2

[0023] Specific embodiment two: a kind of preparation method of high porosity porous ceramics is carried out according to the following steps:

[0024] 1. Weigh 45% to 70% of submicron ceramic powder, 0.9% to 1.8% of binder, 0.5% to 0.9% of dispersant and 26.3% to 53.6% of solvent according to mass percentage, and ball mill after mixing. Obtain a uniformly dispersed slurry;

[0025] 2. Put the slurry obtained in step 1 in a vacuum chamber, and vacuum degassing for 10-20 minutes;

[0026] 3. Test the supercooling point of the slurry treated in step 2, and obtain the supercooling point as T 1 ;

[0027] 4. Cool down the slurry treated in step 2 to T 2 ,T 1 +1℃≤T 2 ≤ T 1 +2°C, supercooled ceramic slurry is obtained;

[0028] 5. Place the supercooled ceramic slurry obtained in step 4 in a closed container with a decompression device, and within 0.5 to 1 minute, reduce the pressure in the closed container to 400 to 10 Pa to obtain a solidified foam material;

[0029] 6. The...

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the submicron ceramic powder in step 1 is oxide ceramics or non-oxide ceramics with a particle size of 0.1-0.9 μm. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com