Large grained fertilizer granulation equipment

A granulation equipment and technology of large granules, applied in fertilizer forms, fertilizer mixtures, fertilization devices, etc., can solve the problems of difficulty in accurately grasping the amount of fertilization, short residence time, easy crushing, etc. The effect of reducing labor intensity and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] manual production

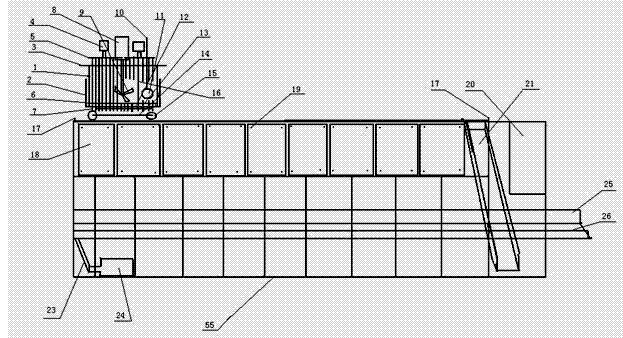

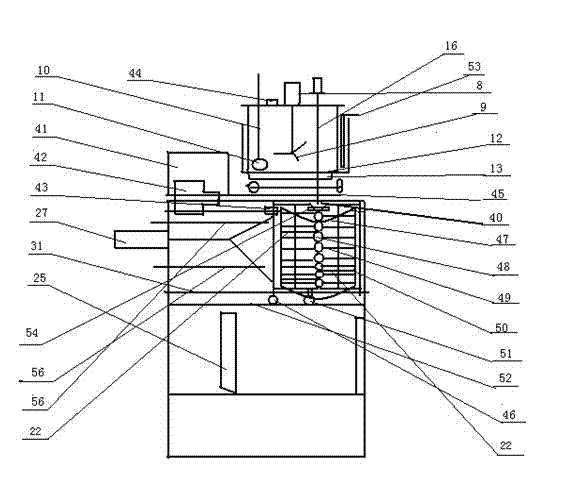

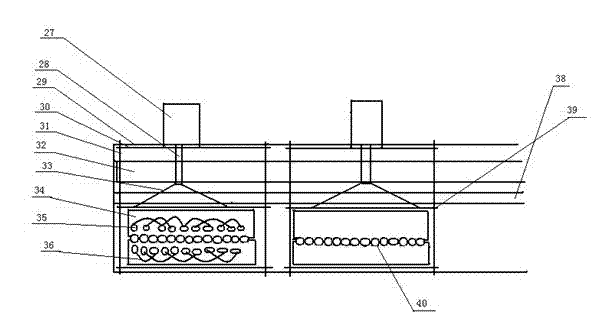

[0024]First fix the clamping frame base 55 firmly to the ground, adjust the height of the control positioning plate 6 in the charging box 1; push the trolley to walk around on the track 29 by hand, and adjust the gear of the trolley motor 42 and the gear rack 38. Tightness. Load onto heat conduction oil to charging box insulation interlayer 2. Turn on all the power, and the PLC computer is designed in manual mode through the PLC handheld programmer. At this moment, the speed-regulating motor 8 of the charging box drives the stirring paddle 9 and starts to rotate. Conveyor belt speed regulating motor 24 and gear chain 23 drive conveyer belt 26 and start running. The circulating water enters the mold cooling circulating water channel 35 through the cooling circulating water pipe 36 through the high pressure water pump and starts to circulate. The electric heating plate 13 and the heat conduction oil heating pipe 53 are energized and heated, so that...

Embodiment 2

[0027] automatic production

[0028] First, fix the clamping frame base 55 firmly to the ground, adjust the height of the control positioning plate 6 in the charging box 1, push the trolley to walk around on the track 29 by hand, and adjust the gear and rack of the traveling motor 42 38 tightness. Heat conduction oil is loaded onto the insulation interlayer 2 of the feeding box. Turn on all the power, and set the PLC computer in automatic mode through the PLC handheld programmer. At this moment, the speed-regulating motor 8 of the charging box drives the stirring paddle 9 and starts to rotate. Conveyor belt speed regulating motor 24 and gear, chain 23 drive conveyer belt 26 and start running. The circulating water enters the mold cooling circulating water channel 35 through the cooling circulating water pipe 36 through the high pressure water pump and starts to circulate. The electric heating plate 13 and the heat conduction oil heating pipe 53 are energized and heated, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com