Brick kiln type biomass gas production furnace

A biomass and gas-making furnace technology, applied in the field of stoves, can solve the problems of high cost and difficult maintenance, and achieve the effects of low cost, long gas production time and large furnace capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

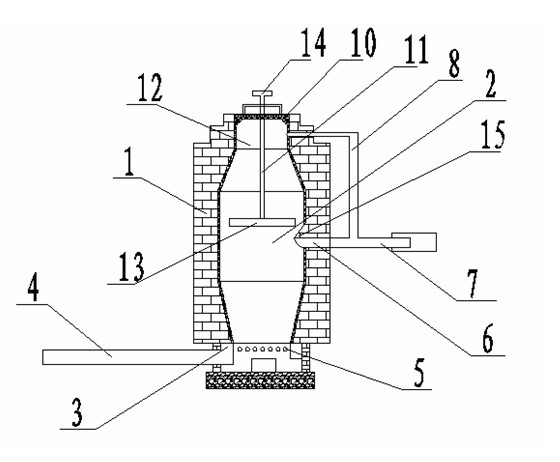

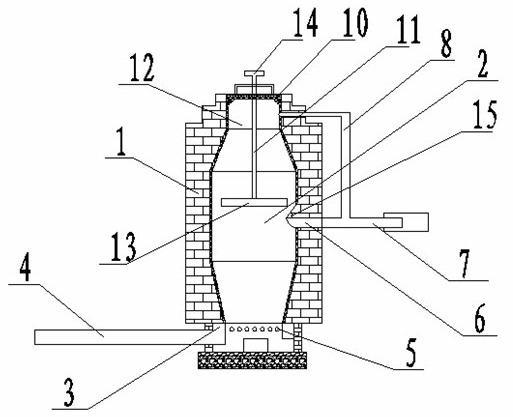

[0010] Such as figure 1 As shown, the brick cellar biomass gas furnace, the furnace body 1 is a brick-concrete structure made of refractory bricks. built. Around the bottom of the furnace 2, an air inlet ring 3 is arranged, the air inlet ring 3 communicates with the air inlet pipe 4, and the inner wall of the air inlet ring 3 is evenly provided with air inlet holes 5, so that the air inlet ring 3 communicates with the furnace 2 A gas outlet channel 6 is provided on the side wall close to the middle part of the furnace 2, the gas outlet channel 6 is connected to the gas delivery pipe 7, and an anti-blocking protrusion 15 is provided on the inner wall of the furnace at the upper part of the gas outlet channel 6. A water return pipe 8 is provided on the upper side of the furnace 2 , and the water return pipe 8 communicates with the gas outlet channel 6 . There is the seal cover 10 that cement steel wire is made on the top of furnace 2 movable. A blanking device 11 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com