Dephenolizing and decoloring refining process and device for cottonseed oil

A cottonseed oil and dephenolization technology, which is applied in the dephenolization and decolorization refining process and equipment field of cottonseed oil, can solve the problems of large amount of entrained oil, reduced evaporation efficiency, and difficult separation of soapstock, so as to reduce refining loss and energy consumption, Improve evaporation efficiency and facilitate the separation of soapstock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

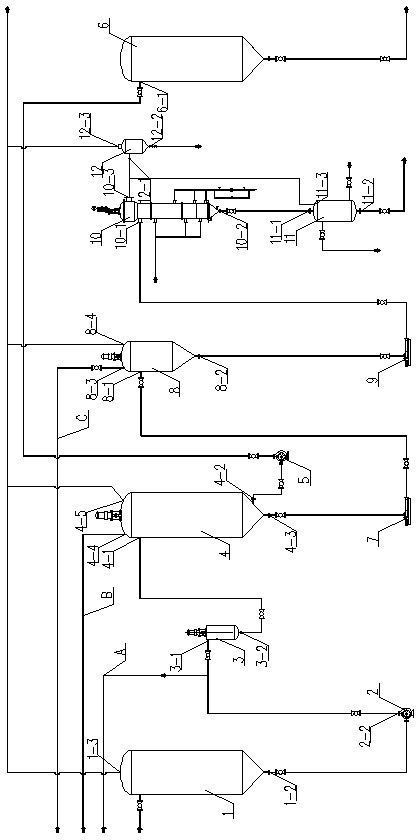

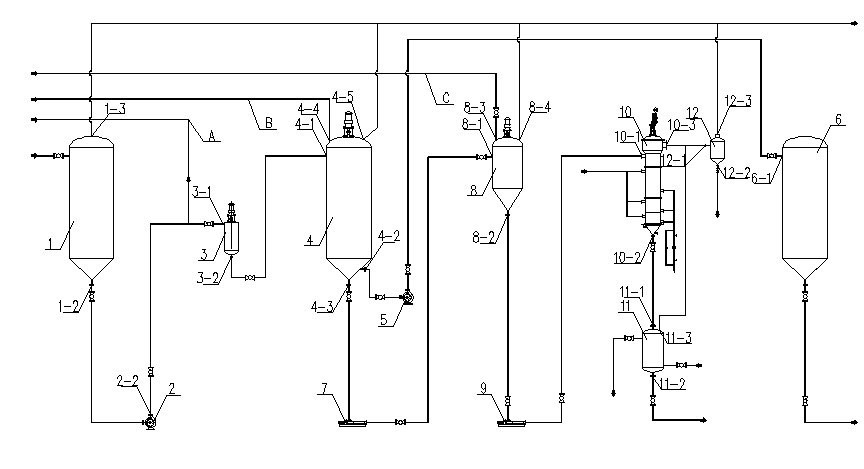

[0017] Such as figure 1 As shown, the dephenolization and decolorization refining process of cottonseed oil, the mixed cottonseed crude oil enters the mixed crude oil temporary storage tank 1, and the pump 2 is pumped out of the mixed crude oil temporary storage tank, fully mixed with quantitative phosphoric acid in the mixer 3, and then enters the reaction tank 4 ; Add quantitative lye in reaction tank 4 to complete degumming, alkali refining, settling and separation after the reaction finishes, mixed oil is pumped into mixed oil temporary storage tank 6 through mixed oil extraction pump 5 from reaction tank mixed oil outlet 4-2, in order to prepare Subsequent refining: the soapstock is pumped into the soapstock temporary storage tank 8 through the soapstock extraction pump 7 from the soapstock outlet 4-3 of the reaction tank, and the soapstock containing solvent is pumped into the desolventization tower through the soapstock temporary storage tank extraction pump 9 10. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com