Steelmaking method suitable for small power electric arc furnace

An electric arc furnace, low-power technology, used in electric furnaces, process efficiency improvement, furnaces, etc., can solve problems such as personal safety threats to workers, affecting continuous safe operation, and high oxygen content, improving the safe working environment and saving blowing blows. The effect of oxygen tube consumption and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

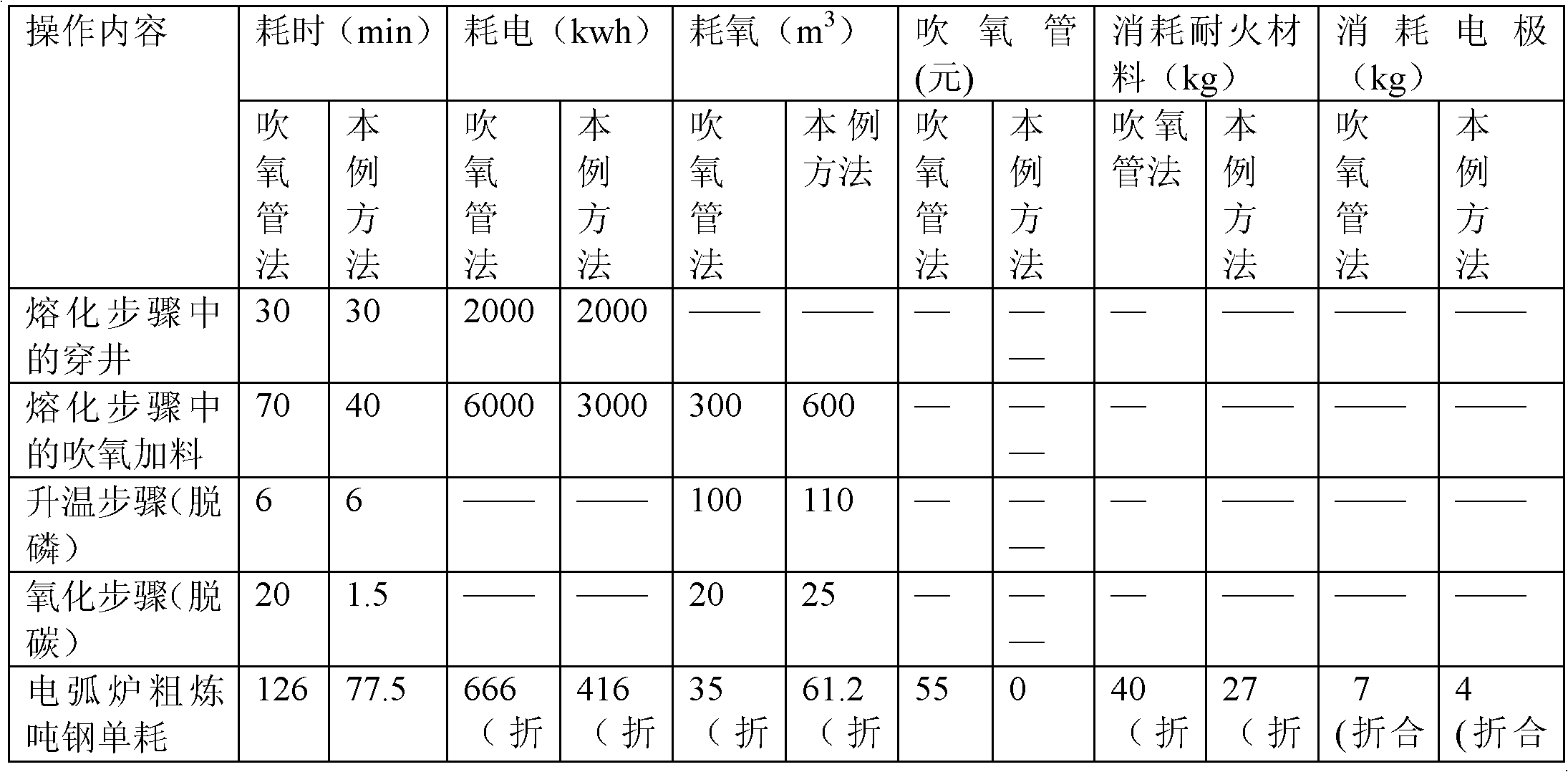

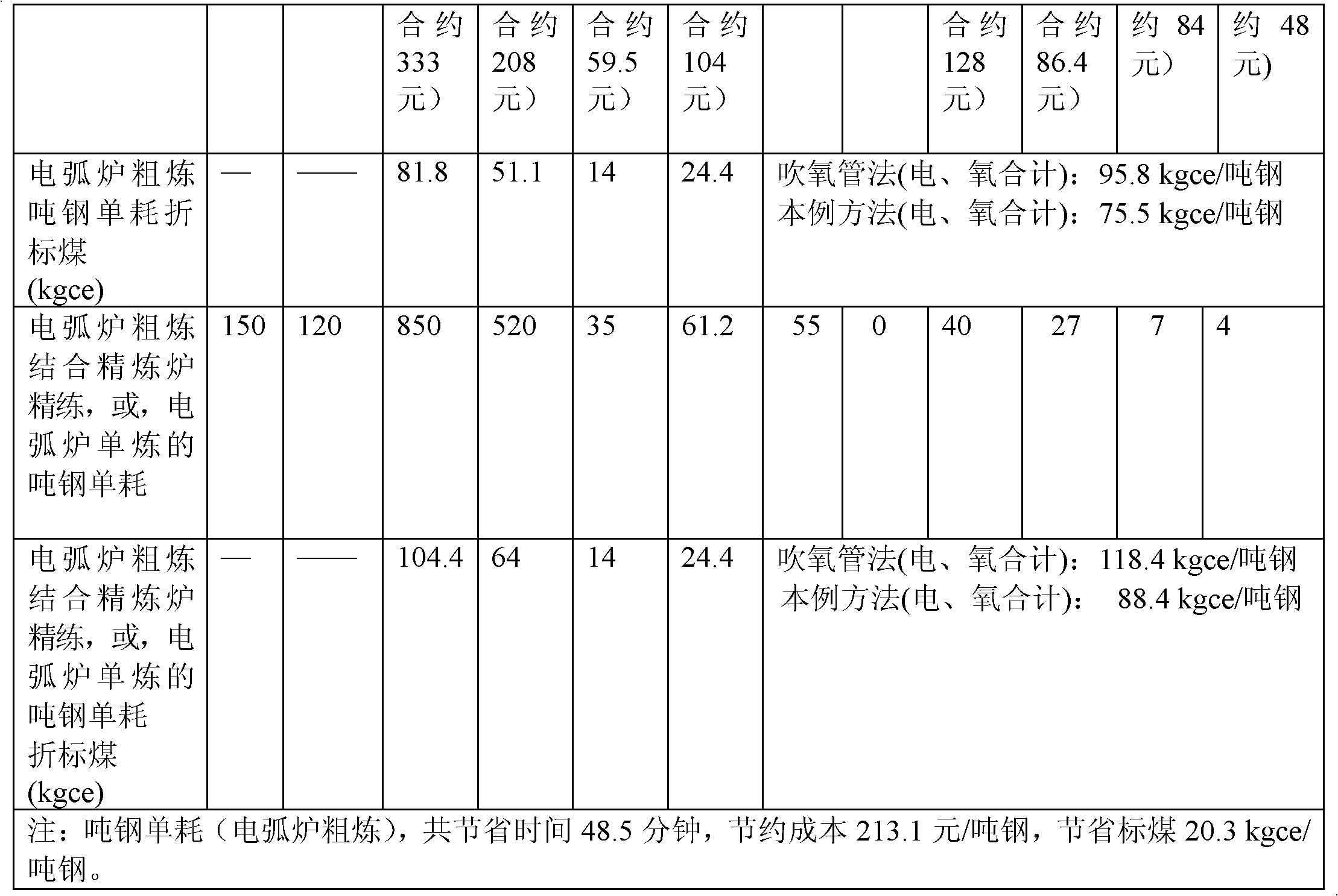

Examples

Embodiment

[0022] A steelmaking method suitable for small-power electric arc furnaces, which includes raw material preparation, melting, oxidation, reduction and tapping, using an electric arc furnace with a nominal capacity of 5 tons and a capacity of 12 tons of molten steel.

[0023] Raw material preparation: 7 tons of fine material (containing 95% lump iron), 5 tons of powder material (0.5mm<grain size<20mm, containing 70% iron), 3.5 tons of other materials (containing 70% iron), iron The total content is 12.6 tons, with 202kg of pure carbon and 300kg of block lime (20mm<grain size<60mm); add the concentrate and other materials mentioned above to the lower layer of the furnace in large blocks, and add medium and small blocks to the upper layer of the furnace ;

[0024] Melting steps: turn on the power of the electric arc furnace, the charge gradually melts, go through the well until there is a molten pool in the furnace, and generate foamy slag; start the furnace door oxygen lance to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com