Electric arc spraying multilayer metal composite plate production line

A production line, multi-layer metal technology, applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of high pollution, shortage, high cost, etc., to achieve convenient manufacturing, smooth board surface, good bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: The multilayer metal composite board produced in this embodiment is an iron-copper-aluminum composite board.

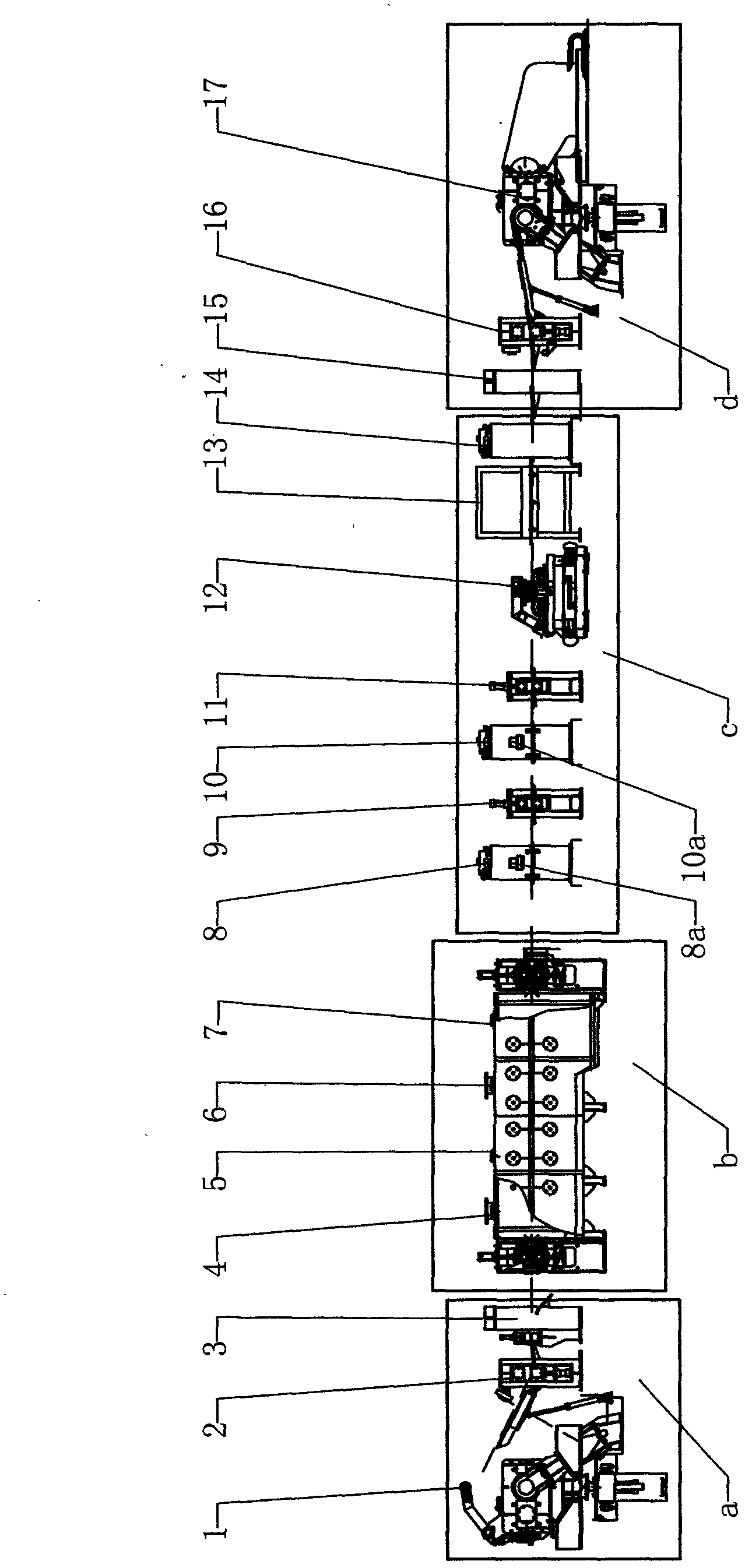

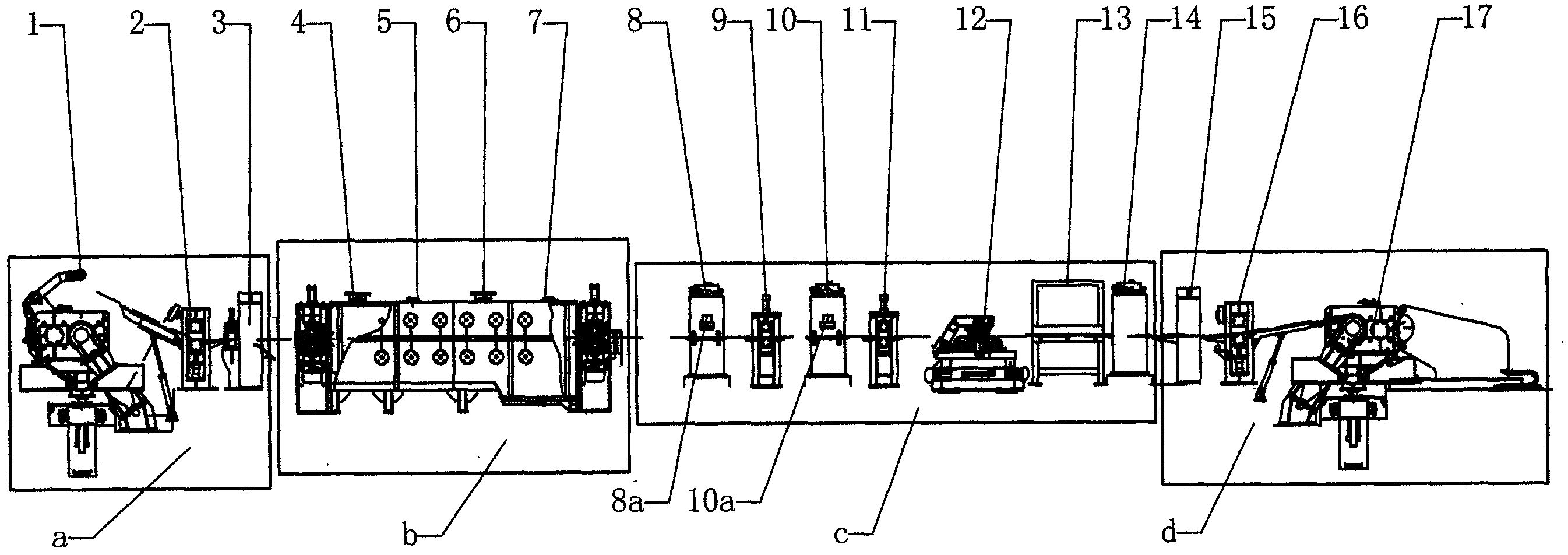

[0015] like figure 1 As shown, a production line for arc spraying multi-layer metal composite panels, which includes an uncoiler 1, an entrance pinch 2, and an entrance shear 3 arranged at the entrance part a of the production line, and a three-roller deviation correcting machine arranged at the processing part c of the production line 12 and detection station 13, the outlet shear 15, outlet pinch 16 and coiler 17 arranged in the production line outlet part d, arranged in the production line passivation part b ultrasonic cleaning machine 4, the first clear water cleaning machine 5, passivation machine 6 and the second clean water cleaning machine 7, and the arc copper spraying machine 8, the first cold rolling mill 9, the arc aluminum spraying machine 10, the second cold rolling mill 11 and the electrostatic oiler 14 arranged in the processing par...

Embodiment 2

[0022] Embodiment 2: The difference between this embodiment and this embodiment 1 is that the multilayer metal composite board it produces is an iron-zinc-aluminum composite board.

[0023] An electric arc zinc spraying machine is used in conjunction with the first cold rolling mill 9 , which completes the compounding of zinc and iron plates after the cleaning and passivation processes. The arc zinc spraying machine can also be a hot-dip machine, which completes the compounding of zinc on the iron plate by hot-dip method.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap