Design method of wind power blade in view of pneumatic and structural balance

A wind power blade and design method technology, applied in wind power generation, wind power generator components, engines, etc., can solve problems such as large amount of calculation, separation of design process by structure priority method, no mature method, etc., and achieve the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

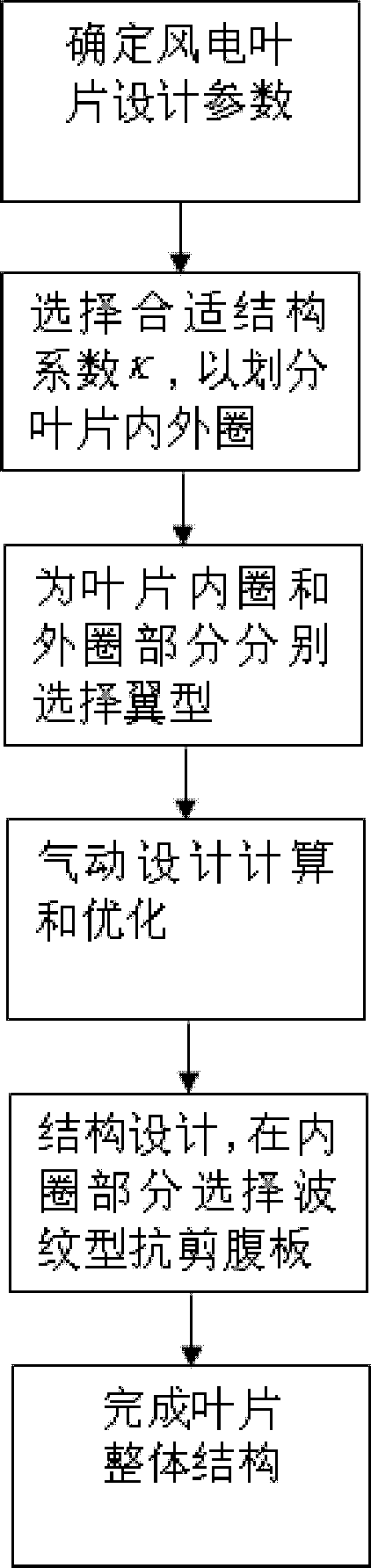

[0043] 101) Determine the design parameters of the wind turbine blades. In this exemplary design, the blade of a certain 1.5MW wind turbine is designed, and its parameters are shown in Table 1.

[0044] Table 1 Design parameters of wind turbine blades

[0045]

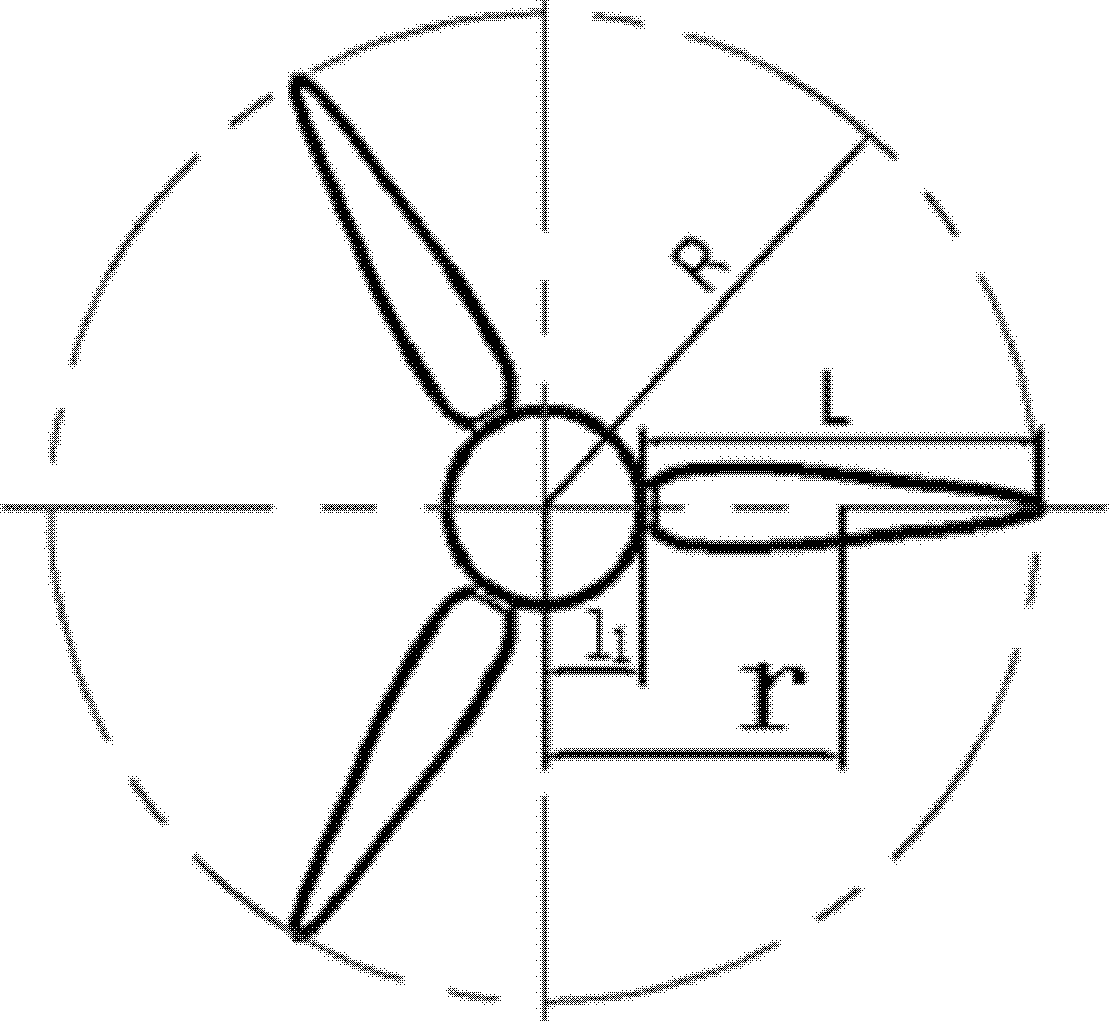

[0046] 102) In this exemplary design, κ=0.55 is selected as the blade boundary, and the blades of the wind turbine are divided into inner ring blades and outer ring blades. 19.25 meters from the root of the leaf to the tip of the leaf.

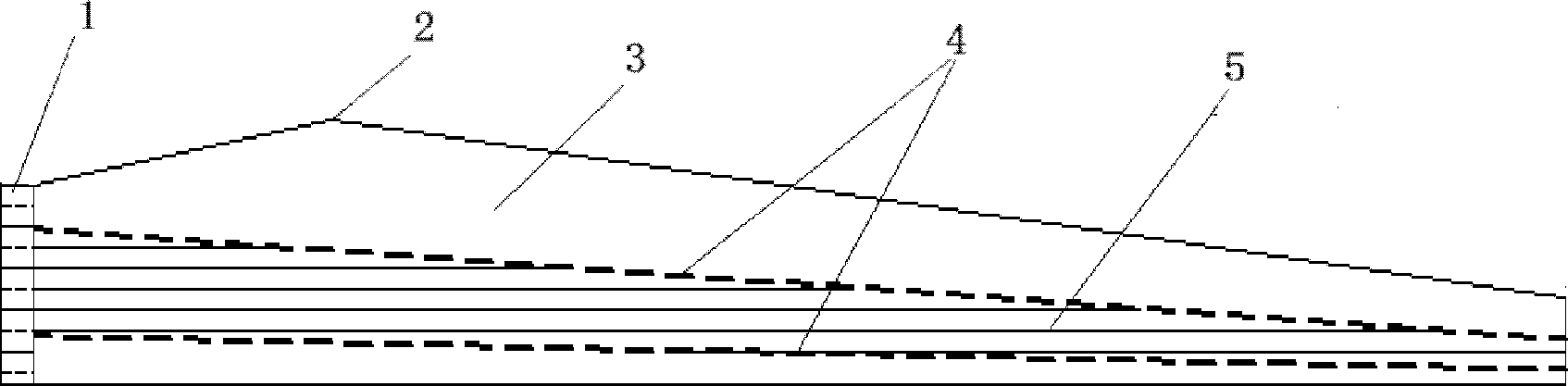

[0047]103) Select airfoils for the inner and outer rings of the blade respectively. In the design process, the wind turbine blades are divided into multiple sections along the span direction to arrange the airfoil. Within the range of 5%~7% of the blade radius is a cylindrical blade root with a relative thickness of 100%; within the range of 7%~25% of the radius, the cylinder gradually transitions to the airfoil, and the relative thickness is 100~33%; 25%~40% of the radius The S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com