Aluminium base built-in raceway roller guide pair

A roller guide rail and raceway technology, applied in the field of linear guide rails, can solve problems such as high environmental requirements, high processing costs, and large inertia, and achieve the effects of simple heat treatment and grinding processes, simple processing and installation, and increased movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

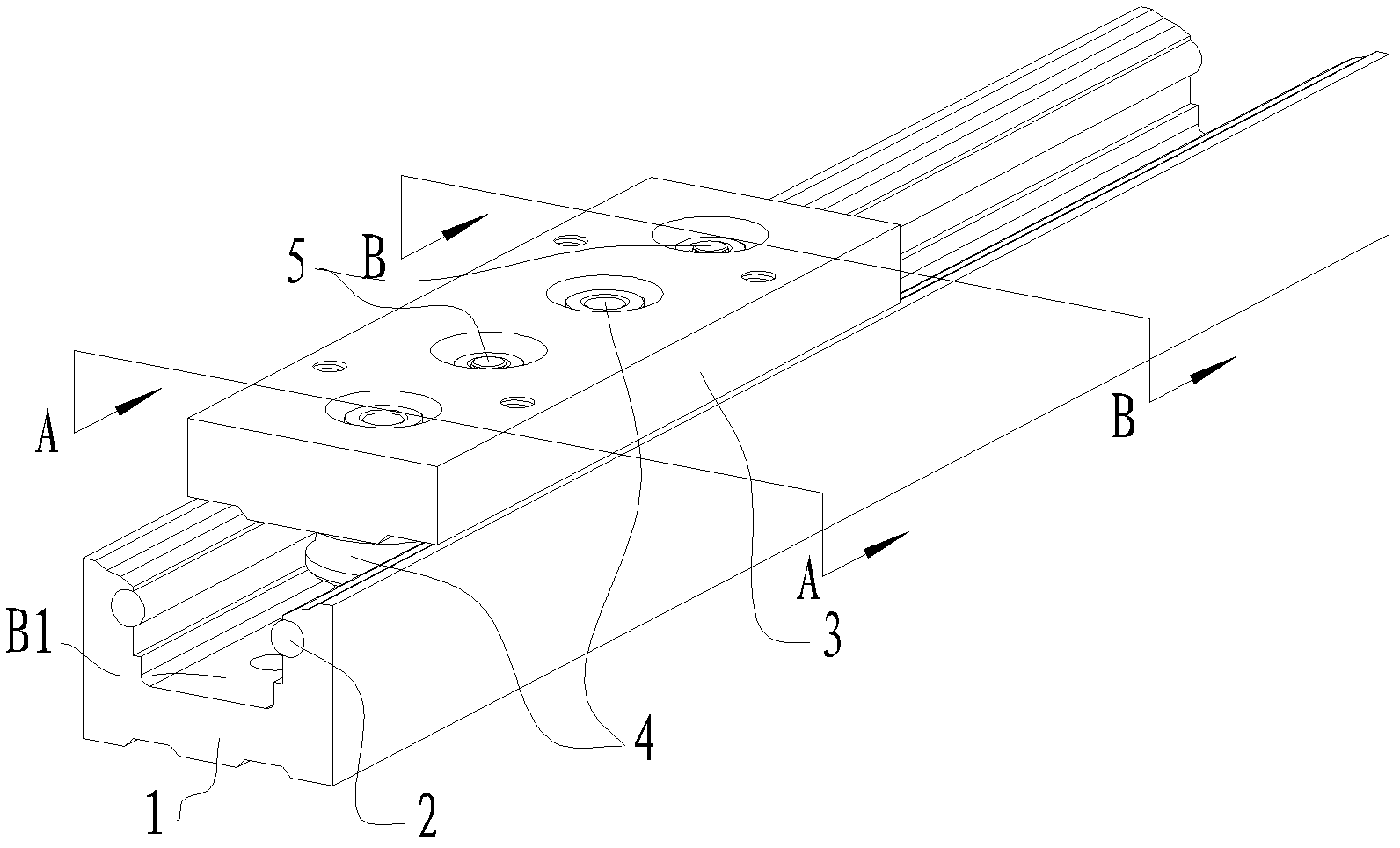

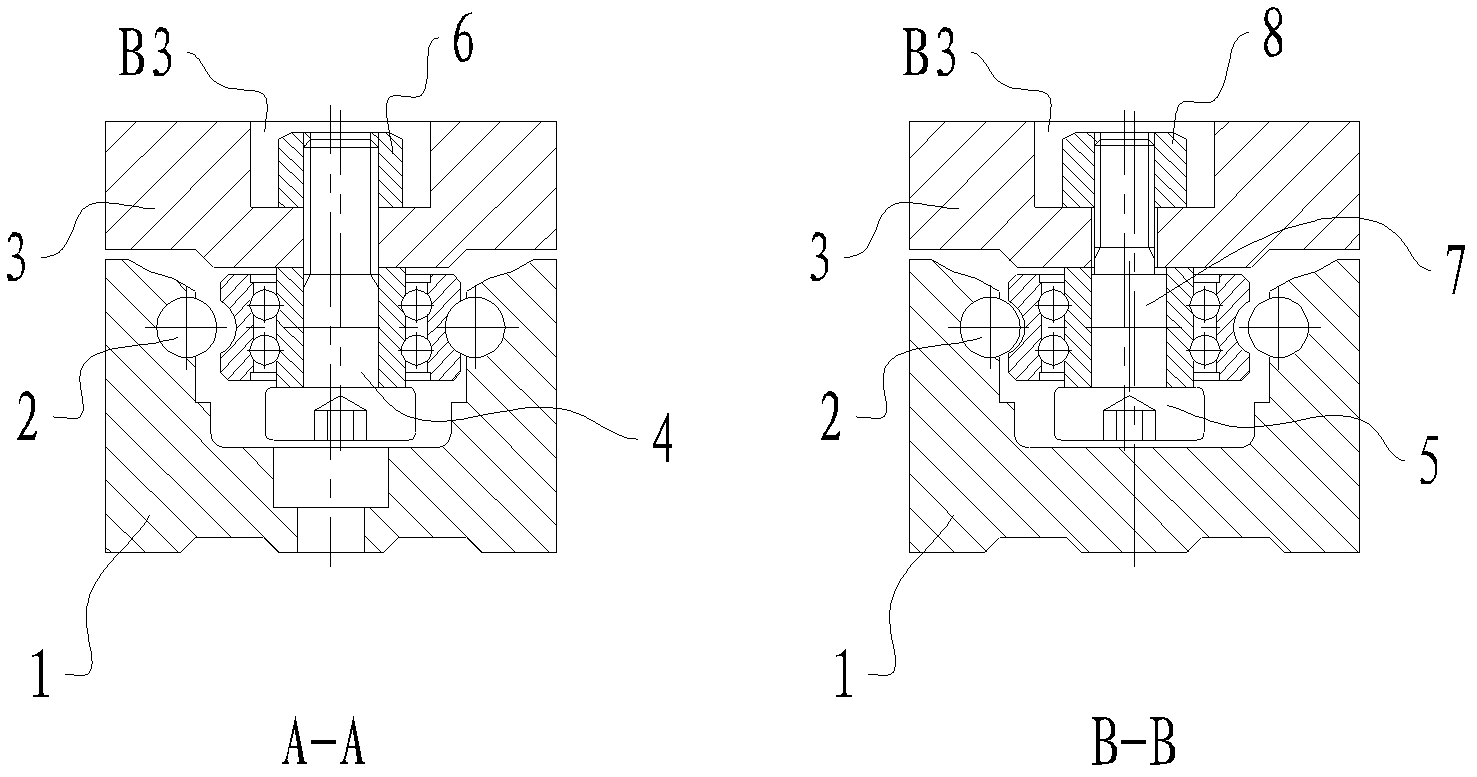

[0023] An aluminum-based built-in raceway roller guide pair, such as figure 1 As shown, there are two parts: an aluminum-based guide rail and an aluminum-based slider. The guide rail part is composed of a guide rail base 1 and two high-hardness steel raceways 2 embedded on both sides of the inner groove of the guide rail base, such as figure 2 , The slider part includes a slider base 3 , a fixed roller set 4 , and an adjustment roller set 5 .

[0024] The guide rail base 1 and the slider base 3 are made of aluminum alloy, and are generally drawn and formed by using precision molds and processed by cutting.

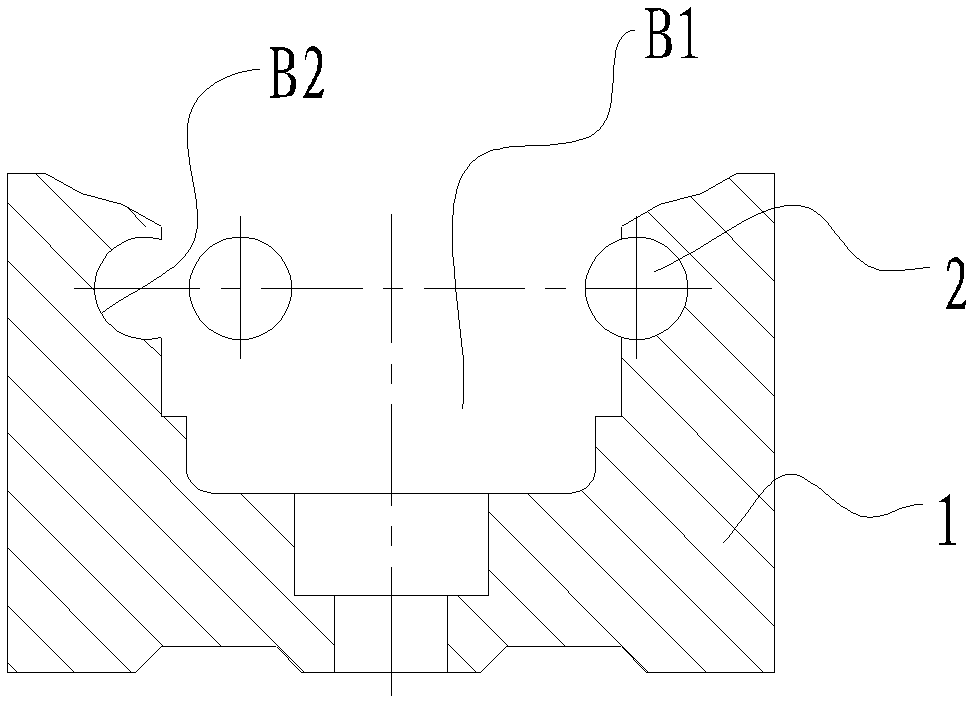

[0025] Such as image 3 As shown, the cross-section of the guide rail base 1 is "concave" and is provided with an inner groove B1. The two sides of the inner groove B1 are provided with grooves B2 conforming to the cross-sectional shape of the raceway 2, and the raceway 2 is embedded in the groove B2. When the load force is small, a guide rail with only 2 raceways can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com