Multi-extreme-working-condition erosion test device applicable to multi-field coupling condition

A technology of extreme working conditions and test equipment, which is applied in the direction of measuring equipment, testing wear resistance, instruments, etc., can solve the problems such as the difficulty in the universality of erosion tests, the inability to realize the coupling verification of multiple working conditions, and the single function. To achieve the effect of authentic and reliable experimental test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

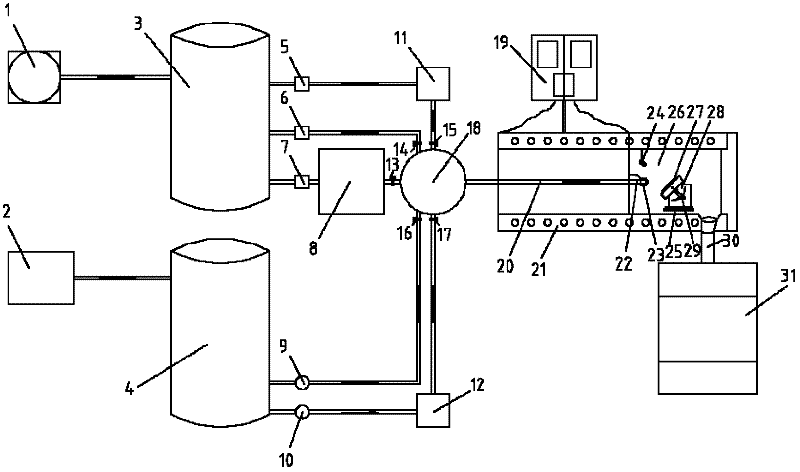

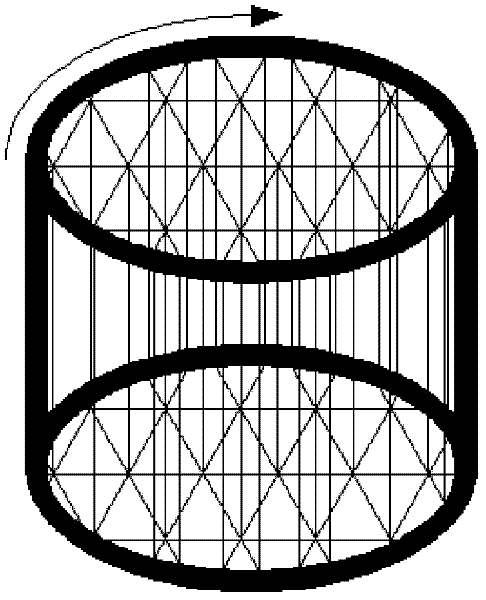

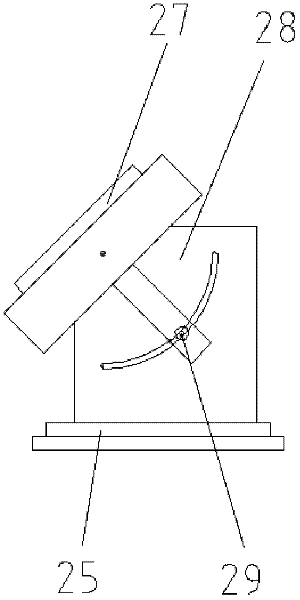

[0023] combine Figure 1-Figure 3 . The multi-extreme working condition erosion test device applicable to multi-field coupling conditions of the present invention is composed of an intake system 1, a booster system 2, a high-pressure gas storage tank 3, a sealed liquid storage tank 4, and a pressure regulation controller 5-7 , Fog making system 8, Flow regulating controller 9-10, Adding device 11-12, Valve 13-17, Mixing device 18, Heating temperature control panel 19, Erosion fluid preheating pipe 20, Heating device 21, Erosion Test nozzle 22, thermocouple 23, high temperature camera 24, high temperature electronic balance 25, erosion laboratory 26, sample to be tested 27, test bench 28, positioning nut 29, erosion fluid overflow pipe 30, erosion fluid cooling Recovery device 31 and cooperate some pipelines and fittings to form. The gas in the high-pressure gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com